Sheet metal deep drawing is an effective and efficient sheet metal forming operation.

In this guide, you will find all information about deep drawing – from step-by-step process, calculations, advantages to defects, just to mention a few.

Keep reading to learn more.

What Is Sheet Metal Deep Drawing?

Sheet metal deep drawing is a metal forming operation.

In this operation, sheet metal blank is subjected to drawing because of compressive and tensile forces.

Sheet metal deep drawing technique

A deep-drawn component has a depth equal to or more than the part radius when drawn.

Learn How Sheet Metal Deep Drawing Process Works

The process of sheet metal deep drawing involves multiple steps. The key steps are as follows:

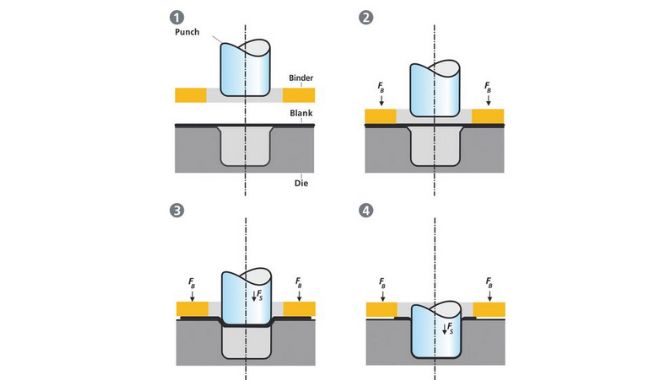

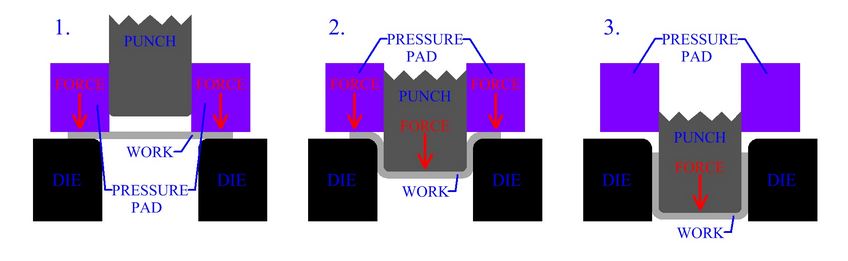

Sheet metal deep drawing process

Step 1: Blanking And Die Placement

Blanking is a process in which you separate a workpiece from a metal sheet.

Then you subject it to press or die.

After this, a blank is ready to place on the die. It would be best if you placed the die on the shank holders.

Step 2: Gripping

In the second step, the shank holder plays their role.

It holds the blank sheet metal right in the center of the die and shank holder.

The optimum pressure aids in this operation.

Step 3: Stretching Inside the Die

After you put your sheet metal blank over the die.

The punch will do its task. It then applies a force over the metal blank.

Consider losing the pressure of the shank holder to ensure a proper stretch within the die.

If you keep the pressure higher, then it will lead to cracking or wrinkling in the final product.

You may also experience thinning during this operation.

Step 4: Part Removal

The last step in the sheet metal deep drawing process is to isolate the final product from the die.

Now it is ready for further finishing processes.

More Resource:

Advantages Of Sheet Metal Deep Drawing

Several benefits exist for the process to make it stand out.

The most noticeable advantages of the sheet metal deep drawing are as follows:

- An option exists to manufacture any geometries you want.

The popular types include rectangular, cylindrical, square, etc. - The cost of manufacturing sheet metal deep drawing is low.

- You can save up a lot of material if you employ using this technique

- The accuracy associated with this process is remarkable.

Each part features high precision. - The sheet metal deep drawing can increase or enhance your productivity level. Using this technique, you can produce more or larger parts per unit of time.

- The parts manufactured using this process are impact resistance.

They have high hardness. - The weight of the products manufactures through this process is low. You can easily handle them.

This method’s cost is also low compared to other methods like progressive stamping.

Limitations Of Deep Drawing Sheet Metal

Some aspects result in certain limitations to the deep drawing sheet metal. The key limitations include the following:

- The method is not cost-effective when it comes to smaller product quantities.

The main reason behind this is the higher cost associated with setting up the press.

Besides this, the level of skill, experience, and expertise requirement is crucial. These things limit the use of this technique for shorter runs. - You cannot use this method for certain industrial products because of defects formation on the specific part.

Factors Affecting the Cost Of Deep Drawing Sheet Metal

Stages in sheet metal deep drawing

Several factors affect the cost of deep-drawing sheet metal. Some of the key factors are as follows:

- If the feature requirement for the specific part is more, then it may lead to the higher cost incorporation

- The location of the feature on the part also matters. Complex locations may also lead to the more cost association

- The next thing is the list is the direction where you want to embed a specific feature

- The size of the part also matters. If you go for greater size, then it will lead you to more costs

- The thickness of the material means if more the thickness, the more usage of material, ultimately leading to more cost

Common Sheet Metal Deep Drawing Defects

Certain things lead to the number of defects in deep drawing sheet metal.

This happens only if you are not following guidelines and incorrectly setting parameters.

Some of the common defects are as follows for your reference:

i. Wrinkling

Tangential compressive and radial stresses are responsible for wrinkling in deep-drawn sheet metal.

Wrinkling takes place in flanges or walls of sheet metal.

Proper process design and appropriate tools can lead to the prevention of this defect.

ii. Thinning and Tearing

These two phenomena result only because of excessive pressure in the shank holder. The excessive pressure prevents the metal blank from moving freely within the die.

This leads to impeccable tensile stresses in a specific region. Les corner radius also leads to the tearing phenomenon.

iii. Defects on Surface

Improper lubrication and low spacing between the die and tool result in the formation of scratching marks on the tool, product, and die.

iv. Earing

The anisotropic behavior of the specific material leads to irregular flange features, especially on deep-drawn parts.

Deep Drawing Calculations In Sheet Metal Fabrication

While manufacturing and designing deep-drawn sheet metal, you need to follow certain calculations:

Sheet metal deep drawn parts

Size Calculation

You can assume that the blank size of deep drawn sheet metal equals the blank surface area of the finished part.

You can calculate the deep-drawn sheet metal blank size by following these steps:

Step 1: Surface Area Calculation

Surface Area of Blank

Step 2: Finish Part Surface area calculation

Surface Area of Finish Part

Step 3: Keep Both S.A Equal

Reduction Ratio Calculation

If the sheet metal part’s depth is large, you need to subject it to more than one drawing operation.

You can calculate these drawing operations numbers using the following formulae:

The DRR decreases as you increase the drawing operations. If you don’t do so, this will result in multiple defects.

The recommended ratio is 50%, 25%, and 20%.

Force Calculation

The next thing in the calculation is determining the force you need to draw the sheet metal.

You can calculate it by following formulae:

d= punch diameter

t= blank thickness

UTS= Ultimate tensile strength

Examples Of Deep Drawn Sheet Metal Parts

Determine the dia. and number of drawing operations to draw a metal sheet with dia. 50 mm and a depth of 60 mm?

Solution:

Cup dia. = 50 mm

Cup depth = 60 mm

= 60.2

Blank Dia. = 60.2 2 = 120.4

DRR Calculation:

Suppose the first drawing operation: 0.5

0.5 120.4 = 120.4 – Punch Dia.

Punch Dia. = 60.2

Hence this value determines you can withdraw a height of 60.2 mm in a single drawing operation.

Therefore, only a single drawing operation is enough to manufacture this part.

Conclusion

Sheet metal deep drawing is a practical and effective in metal fabrication process.

With the information in this guide, certainly, you can get high quality and reliable parts.

For any questions or inquiry in sheet metal deep drawing process, contact us now.