Silk Screen Printing on Metal

Probably, when you heard the word silk screen printing, you may think about printing emblems, logos, or designs on fabric or clothing. However, silk screen printing is also an important process in metal fabrication. This guide will help you understand the role of silk screen printing when it comes to metal fabrication.

We will discuss the definition, process, technical aspects, suitable ink, advantages, and metals that are used for silk screen printing. The goal of this article is to give you a better understanding and knowledge about silk screen printing on metal. Scroll down to read and learn more!

What is Silk Screen Printing in Metal?

Silkscreen printing is a process for metal finishing. Most people know this process as serigraphy. In this process, a certain design and paint are applied to a metal. The materials that are used for silk screen printing are blades and squeegee. It also uses a fine polyester mesh for applying the paint to the metal.

To ensure that the ink is not messed up on the metal surface, the section that is not included is guarded by a stencil. By using a stencil, a perfect design or exact printing can be achieved.

Common Applications of Silk Screen Printing on Metal

Silkscreen printing is an affordable and easy way to customize different metal products such as:

- Metal stamps

- Panel graphic overlays

- Nameplates

- Metal enclosures

- Advertising items

- Aerosols

- Industrial components

- cutlery

- Cans, and more

The silkscreen printing process is commonly used for customizing metal products such as logo and design printing.

Applicable Metals for Silk Screen Printing

Silkscreen printing is applicable for different metal substrates such as:

- Stainless steel

- Powder-coated metals

- Painted and anodized metals

- Cast iron

- Aluminum

- Brass

- Bare or varnished metals, and more

Metal Silk Screen Printing for Excellent Color Matching

When performing silk screen printing on metal, the most common challenge that will encounter is the matching of the exact color. To achieve the desired finish, the most manufacturer uses U.V cured inks.

Also, with the use of a color matching system and advanced equipment, excellent color matching can be achieved. With the use of all these high technologies, accurate color schemes will meet industry standards.

Why You Should Understand Different Metal Substrates Before Screen Printing on Metal

When it comes to screen printing on metal surfaces, it involves printing on different substrate types such as treated or coated metals. Understanding the different metal substrates before silk screen printing allows for a successful finish. There are two categories of metal coatings.

Thermoplastic Coating

The metal that has thermoplastic coatings will not react chemically when dried. This makes the coating very soft and can absorb more ink. However, this type of coating is not resistant to aggressive solvents, scratch, and high heat.

Due to the strong solvent or heat produced by screen printing, the thermoplastic coating can be melted again.

Thermoset Coating

To achieve a metal with a thermoset finish, the material will undergo a baking process at a high temperature. It offers heat resistant and scratch-resistant. Therefore, this type of coating is more durable. These are also resistant to scuffing and solvents.

These two coatings (thermoset and thermoplastic) have a big effect on your silk screen printing finish on metals.

Different Types of Ink Used for Silk Screen Printing on Metal

UV-cured inks are less common ink that is used for metal silk screen printing. However, its unique properties such as chemical bonding makes it popular recently. This ink offers a scratch and scuffing resistance final result.

If baked, this type of silk screen printing ink offers a very secure bond. Examples of heat-cured solvent inks are the following:

- Acrylics

- Enamels

- Polyesters

- Epoxies

The heat-curing technique used in this ink allows it to offer extreme durability. Whether you need to screen print a metal product that will be used for outdoor applications, heat-cured solvent ink is the ideal choice.

When using air-dried solvent ink, the air curing process is eliminated. Therefore, it is ideal for screen printing metal products for outdoor applications. It is available in different formulations such as:

- Lacquer-base

- Acrylic-base

- Vinyl-base

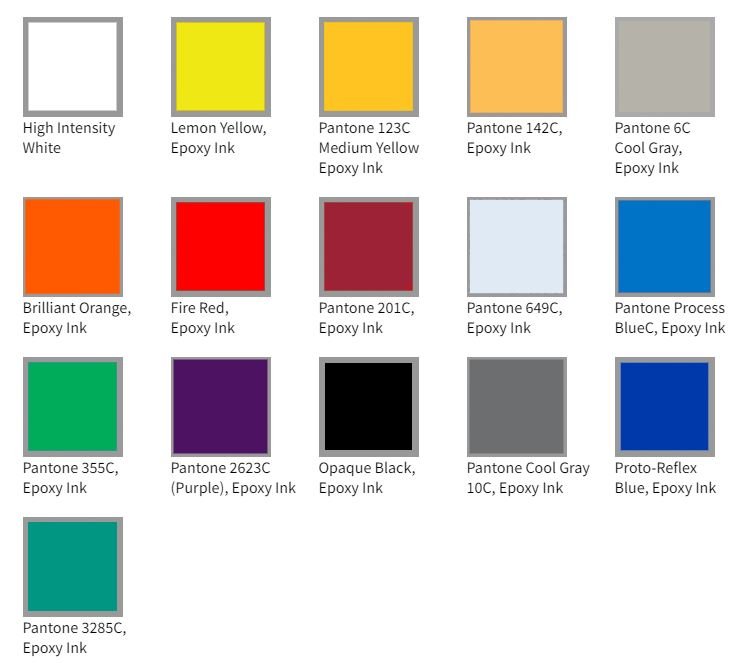

- Different Colors for Metal Silk Screen Printing

Project Gallery

How to Choose a Suitable Ink for Metal Silk Screen Printing

Whatever type of ink you will use, you should make sure that it will meet specific job requirements. Different ink types should be used to match different metal coating and applications.

If the metal product to be silk screen printed is intended to use for interior applications, you can use epoxy-based inks. A resin-based heat-cured ink is also ideal for metal products for indoor applications.

You can also choose solvent-based ink that is air-dried for metal products that don’t require solvents. On the other hand, if the metal component is used for applications that require durability and solvent resistance outdoor, choose a UV-cured or conventional heat sink rather than an epoxy-based one.

Ink selection is very important when it comes to silk screen printing on metal. When working with different ink types, the process should be monitored carefully.

Metal Silk Screen Printing Process

Below are the different processes when working with silk screen printing on metal.

- Making of artworks and designs to be printed on the metal surface.

- The artwork is printed on the transfer film.

- Choosing a specific size of the screen and placing a liquid emulsion in a dark environment.

- The baking process is the next step. The baking process is used for solidifying the screen emulsion.

- The transfer film that is printed with the design is placed on the screen.

- This time, the screen should be ready for printing.

- Then, the silkscreen is placed on top of the metal surface.

- The chosen type of ink is placed on the screen and is wiped and pushed through the negative image using a blade or squeegee.

- The last step is the screen removal to let the complete printed metal dry.