Do you want to use 430 stainless steel for multiple purposes? Read this guide.

It will explore everything from the composition of this ferritic stainless steel to its unique properties. Whether you want to manufacture aircraft appliances or domestic equipment with 430 stainless steel, this article will guide you through everything.

Let’s dive into it:

What is 430 Stainless Steel?

430 stainless steel contains 17% chromium and 0.75% nickel. Each component performs a specific role in the specialty of 403 stainless steel. This stainless steel is known as ferritic stainless steel.

The corrosion resistance of this material is increased due to presence of chromium, hence life of this material extends. This stainless steel does not require any hardened work to form; you can get it simple by stretching, bending, or drawing operations.

430 stainless steel performs well in a neutral pH and a slightly acidic environment. This ferritic stainless steel performs better in conditions where the corrosion resistance of metal matter is higher than its strength. That’s why this material is applicable in the cosmetic industry. We can use 430 stainless steel to form kitchen gadgets and industrial appliances.

430 Stainless Steel’s Composition

| 430 Stainless Steel Components & Percentage(%) | |

| Chromium | 16.0-18.0 |

| Nickel | 0.75 |

| Carbon | 0.12 |

| Manganese | 1.00 |

| Silicon | 1.00 |

| Phosphorus | 0.04 |

| Sulfur | 0.03 |

Properties of 430 Stainless Steel

Corrosion Resistance

You can use 430 stainless steel to form chemical handling apparatus because of its cossosion resistance applications. This material is also usable in saltwater, there it form a brown layer.

Heat Resistance

This ferritic material can be used at 815°C. Besides this, it’s little applications could be found up to 877 °C. This material could not deformed, therefore you can get prolonged services at 400-600°C.

Formability

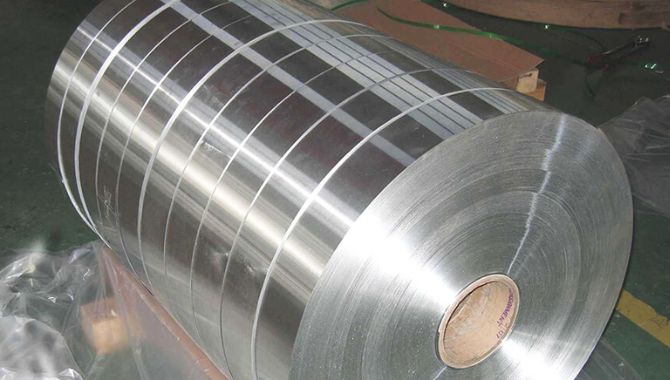

Another excellent property of 430 stainless steel is formability. You can easily turn this stainless steel into various shapes like sheets, coils, plates, or whatever you want.

This stainless steel has the ability to be bent , drain and rolled. As a result, you can use this stainless steel for industrial purposes where different steel shapes are needed.

Welding

430 ferritic stainless steel offers fair weldability services. All types of welding techniques are applicable to this stainless steel, so you can opt for resistance welding or fusion welding.

But before welding, preheating is recommended at 150 to 200°C. When annealing of 430 stainless steel is done at 790 to 815°C, the heat-affected area may relieve embrittlement.

Heat Treatment

The 430 stainless steel become hardened, when heat treated. Heat treatment is a process in which the material softens or hardens under high temperature.Annealing of 430 stainless steel processes consist of:

Heat the material at 815°C then soak it for 30 minutes. Keep in mind that the thickness of the material should retain 25mm, then cool down the material at 600 °C in the furnace. After this do air cooling. If you want more brittle components then cool down the material between 540 to 400°C.

Machinability of 430 Stainless Steel

430 stainless steel is machieneable. You can enhance your stainless steel machining for industrial purposes by following these tips:

- Dull edges can cause the work to be hard, so keep the cutting edges sharp.

- To prevent work from hardening, try to set the cuts light but deep.

- To ensure that the swarf stays away from the work, you can use chip breakers.

- Because austenitic alloys have low thermal conductivity, heat concentrates at the cutting edges. Therefore, coolants and lubricants are required in significant amounts.

Specific Properties of 430 Stainless Steel

| Annealed and Thermal Properties and Values | |

| Annealed Temperature | 790–835 °C |

| Stress Relief Annealing | 430–595 °C |

| Density | 7.62 to 7.82 Mg/m3 |

| Hardness | 1500 to 1950 MPa |

| Melting Point | 1,425 to 1,510 °C |

| Specific Heat | 450 to 530 °C |

| Yield Strength | 345 MPa |

| Tensile Strength | 430 to 600 MPa |

| Modulus of Elasticity | 195 to 205 GPa |

| Thermal Conductivity | 23 to 27 W/mK @ 23 °C |

| Maximum Service Temperature | 815 °C |

| Minimum Service Temperature | -40 to -70 °C |

| Coefficient of Thermal Expansion | 10.4 to 10.8 x 10-6/°C |

Benefits of 430 Stainless Steel

430 stainless steel exhibits various significant benefits interlinked with its usage in multiple fields. Here are some key benefits:

- Corrosion Resistance: 430 stainless steel can’t corrode, therefore used in multiple industries such as in the food industry to make food processing appliances. Moreover, these alloys give protection against moisture and a salty atmosphere; hence, could be used in weather resistant applications.

- Strength: The strength of 430 stainless steel is another factor that offers various benefits in industrial usage. Alloys exhibit good mechanical properties like ductility, which is why the formation of various shapes is possible. Furthermore, manufacturing your products with the aid of this alloy can enhance their longevity, thus eliminating the need for extra maintenance. Hence, you can get cost-effective products in the long run.

- Magnetism: Because of magnetic behavior, this ferritic stainless steel is beneficial to use in various machinery and electromagnetic applications, such as forming different solenoids, magnetic sensors, etc.

- Thermal Conductivity: 430 ferritic stainless steel has 26.1 W/mK heat resistance, these materials are beneficial to use in areas that are closer to engines, where temperatures can exceed.

- Aesthetic Appeal: This property contributes to a wide range of applications of 430 stainless steel. The alloy offers advantages in places where seamless visual consistency is required.

- Recycling: the 430 stainless steel is recyclable, therefore giving advantages in sustainable manufacturing. The material melts down without losing its chemical properties; therefore, the need for new raw materials is reduced. Ultimately, we can say 430 stainless steel is less costly than other aesthetic stainless steels.

Different forms of 430 Stainless Steel

430 stainless steel could be formed in various shapes according to the needs of the industrial application. The forms also rely on the processes you applied to the material. Here are some common forms:

Sheet

To make sheets of 430 stainless steel, it’s cut down in rectangular shapes. 0.5 to 3.5 mm should be the thickness of the sheets. These are formed from both hot and cold rolls.

To get a hard and strong sheet, choose the cold-rolled technique, where ferritic stainless steel undergoes degrees of work hardening. In contrast, if you choose a hot-rolled method, you can get soft, annealed sheets with maximum ductility.

The edge of the 430 stainless steel sheets can be different with different rolling processes. To get fully round edges, just roll them as they are. If your purpose is to get skived edges, just single pass cut the sheet, and in the third case, if you want slit edges on your sheets, cut the edge in square.

Bar

This is a product of 430 stainless steel in a hexagonal strip shape. You can form this shape of 430 stainless steel by cold or hot rolling. The choice of method depends on the specific hardness that you require. Bar shapes are available in regular and irregular profiles, and you can get them according to your industrial needs.

Plate

Plate stainless steel products are manufactured in exactly the same way as sheets. Plate shapes are similar to sheets; the difference lies in thickness. A thickness of up to 3 mm is considered a plate rather than a sheet. This ferritic stainless steel is supplied to you in a rolled thickness of 100mm, where work-hardened, annealed states are required.

Hot Rolled

Reduce the thickness of the plate, sheet or stripe by using pinch rollers to form hot rolls. You can get variable thickness through this process with an unprofessional black or blue surface on the material. This material comes with full softness and maximum ductility.

Cold Rolled

If you want more precise material, you can opt for the cold rolling technique, which is processed after hot rolling. This technique is applied for operations where a reduced thickness is required. Cold rolling also improves the surface finish of the stainless steel.

Annealed

The annealed material comes with full softness. Annealed material is gradually cooled down from red heat to get crystal material. When you proceed with cold work, it breaks large crystal bodies into small ones and produces high stress on crystal boundaries. As a result, you become able to achieve higher hardness, stiffness, and strength but lower ductility.

What are the Applications of 430 Stainless Steel?

430 stainless steel is used in multiple industries related to its properties. Here are some applications:

- Automotive Industry: manufacturers of automotive industries use 430 stainless steel to manufacture the frames of airplanes, grills, trims or exhaust systems. These stainless steels are also used as structural components in aerospace.

- Machinery Component: 430 stainless steel is ideally used to craft solenoids, actuators and other magnetic sensors. The magnetic properties facilitate their usage in motors and transformers.

- Domestic Appliances: 430 stainless steel is used to manufacture domestic equipments because of its unique properties. As 430 ferritic stainless steel can handle moderate temperatures without excessive heat, it is therefore effectively used in other kitchen equipment. The appliances may include oven liner, pots, pans, sinks, and other items. You can use 430 stainless steel to form other domestic equipment, such as dishwashers and washing machines.

- Architectural Applications: As discussed earlier, this grade of stainless steel comes in various forms with a finished touch, therefore giving your products a bright, polished look. As a result, you can use them in a variety of design contexts, including handrails, window frames, door frames, and decorative trim.

- Chemical Industry: 430 stainless steel is ideally used by some chemical industries, who use it to manufacture chemical storage tanks and heat exchangers, because of its corrosion resistant property.

Conclusion

As you have read, 430 stainless steel plays a crucial role in many industries that manufacture various appliances.

Knowing the composition, benefits, forms, and properties is necessary when dealing with 430 stainless steel.

If you want 430 stainless steel for any of the above applications, contact us. At KDMFAB, we will provide you with the best 430 stainless steel material.

FAQs

Compare 430 Stainless Steel with 316 Stainless Steel.

316 stainless steel is generally more resistant to chemicals and is used in various applications, such as dealing with salt and strong acids. However, 430 is good for food-grade steel sheets that need moderate resistance. Because of their corrosion resistance and recyclability, they offer a less-cost alternative for the manufacturing process.

Is 430 Stainless Steel Better than 304 Stainless Steel?

Grades 430 and 304 both come with rust and corrosion resistance. Grade 304 provides more corrosion resistance because of nickel, but these are more expensive. Grade 430 stainless steel is where cost and appliance longevity is considered.

Differentiate 410 and 430 Stainless Steel?

These stainless steels differ from each other because of chromium concentrations. 430 stainless steel has 18%, then 410 stainless steel, which includes 16%. The amount of chromium differentiates their usage as well, as more chromium means more resistance to corrosion and more wide applications.

How is 430 Stainless Steel Magnetic?

The magnetic properties of this ferritic stainless steel are due to its structure. Unpaired electrons and iron atoms in 430 grade give it natural magnetic behavior. In annealed as well as cold rolled, these are magnetic.

Is 430 Stainless Steel Food Safe?

430 stainless steel’s chromium content is about 16 to 18% chromium, therefore it is ideal for applications where moderate corrosion resistance is required. Therefore, this ferritic material is considered good for food-grade appliances.