KDM offers full sheet metal fabrication services to produce high precision and complex parts using different sheet metal materials.

KDM offers full sheet metal fabrication services to produce high precision and complex parts using different sheet metal materials.

KDM offers full sheet metal fabrication services to produce high precision and complex parts using different sheet metal materials.

KDM – Professional Sheet Metal Fabrication Factory in China

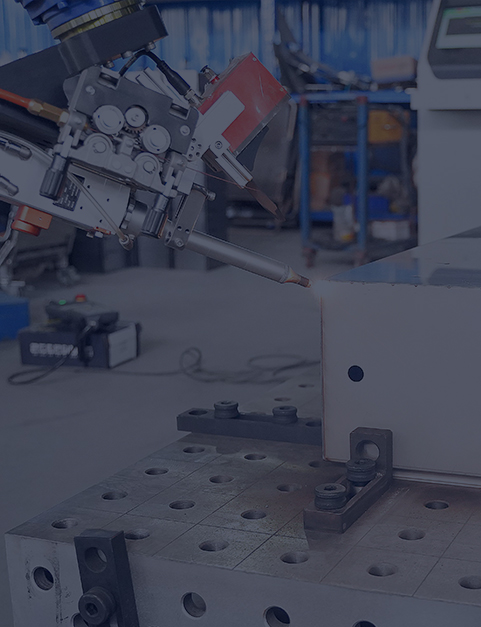

KDM offers sheet metal fabrication for producing different products, structures, and parts. We can provide different fabrication processes including stamping, welding, bending, assembly, laser cutting, and more. Our engineers can bend, fold, or cut different sheet metal materials to form any shape.

We are equipped with advanced fabrication equipment such as special tools. KDM has high-quality chop saws, band saws, and other tools that are essential for sheet metal fabrication.

KDM is also integrated with world-class press brakes. It allows us to create a very sharp angle and bend to the sheet metal. Different industries such as aerospace, automotive, and construction can benefit from our sheet metal fabrication.

If you need custom sheet metal fabrication services, choose KDM as your manufacturer!

Custom Any Sheet Metal Parts for Your Project

KDM has full capabilities in customizing any sheet metal parts through our fabrication services. We can manufacture according to your specific designs, shapes, sizes, surface finishes, thicknesses, and more. Our engineers can customize your orders through the following services and processes:

- We use laser cutting for easy and precise sheet metal cutting.

- KDM uses punching techniques for forming perforations such as countersinks, ribs, etc.

- We offer to bend or folding process by using press brakes.

- KDM uses different welding techniques such as spot welding, TIG welding, etc.

Aside from that, KDM is also an expert in sheet metal assembly, burning, hole punching, drilling, shearing, and more.

Recent Sheet Metal Fabrication Parts

These sheet metals are lightweight and suitable for low temperatures. It is widely used for electrical devices, automotive, and more.

KDM offers stainless steel mailbox with rust protection features, easy installation, large capacity box, fully assembled drilled holes.

Our sheet metal picture frames are available in a wide range of material selections such as alloy, iron, aluminum, stainless steel, and more.

The first aid cabinets feature a powder-coated body and locking key. Some first aid cabinets feature a frosted glass door with a medic cross symbol.

KDM manufactures custom metal nameplates including overlaminate aluminum, screen printed aluminum, engraved aluminum, and more.

We manufacture stainless steel fuel tanks with high-pressure resistance. It also features lightweight and sustainable materials.

Our custom aluminum front panel is constructed with a two-part or one-part panel option. It features corrosion resistance, is lightweight, and is strong.

KDM is a supplier of LED screen cabinets with modular units, large size capacity, lightweight aluminum, and more optimal features.

Custom Sheet Metal Fabrication for Different Industries

KDM can fabricate any sheet metal parts for your applications, just send us your drawing and get our best quote.

Our fabrication services can produce aluminum and steel parts that are ready to use for spacecraft or aircraft.

KDM can produce automotive parts such as side panels, fenders, and hoods through our sheet metal forming capabilities.

We can provide sheet metal fabrication for producing construction parts such as corrugated siding, roofing, and more.

Why KDM is Trusted by 1000+ Clients

Our sheet metal fabrication covers a lot of benefits to many industries, businesses, or projects. Below are the advantages of our services.

We can quickly produce different sheet metal prototypes and final products. KDM offers speedy production while assuring high precision. Our high-volume production also allows us to have cost-effect sheet metal fabrication services.

Through our advanced sheet metal fabrication, we can produce sheet metal parts that are lightweight yet durable. We assure high strength, scratch resistance, and corrosion resistance to all produced sheet metal products.

We are experts in different sheet metal fabrication techniques that allow us to produce complex parts with additional intricate features such as notches, slots, holes, etc. Our wide range of sheet metal materials can also withstand electrical, high heat, corrosion, and more.

Sheet Metal Fabrication Equipment and Tools

KDM is well-equipped with tools and equipment for sheet metal fabrication such as:

- Robotic Welders

- Laser Cutting Machine

- CAD Design Software

- Sheet Bending Machine

- CNC Punch Machines

- Automated Press Brakes

- CMM Technology

- Prototyping Technology

Available Surface Finishes

KDM offers a wide range of custom surface finishes that gives additional protection, durability, and appearance to sheet metal products.

- Sandblasting

- Powder Coating

- Geomet

- Anodizing

- Hot Dip Galvanized

- Electro Coating

- Screen Printing

- Trivalent Zinc Plating

Material You Can Choose for Your Sheet Metal Parts

KDM uses a wide range of material selections for our sheet metal fabrication process. Among our materials are aluminum, stainless steel, brass, magnesium, copper, carbon steel, bronze, galvanized steel, and more. Each material is available in different grades and varieties. Rest assured that all the materials used for your sheet metal parts are durable, corrosion-resistant, long-lasting, rust-proof, wear-resistant, and high-performance. If you want a specific material to be used in the sheet metal fabrication process, don’t hesitate to contact us!

- Carbon Steel

- Stainless Steel

- Aluminum

- Brass

- Copper

- Magnesium

- Bronze

- Galvanized Steel

Our Enclosures Applications

KDM offers custom sheet metal fabrication for creating structures, machines, and parts that includes:

- PLC Enclosure

- Instrument Enclosure

- HMI Enclosure

- Control Station Enclosures

- Traffic Control Enclosures

- climate controlled enclosure

- Push Button Enclosure

- Control Cabinet Enclosure

- Operator Console Enclosure

- Distribution Board Enclosure

- EV Charger Enclosure

- Outdoor Telecom Enclosure

- Solar battery enclosure

- Telecommunications Enclosures

- Network Cabinets

What Our Customer Say

“I am looking for a sheet metal that needs to be formed and KDM did a great job! The turnaround time was very fast and they are very quick to work. KDM team is a very nice supplier to work with.”

Karlfrom Thailand

Karlfrom Thailand“I always approved KDM sheet metal fabrication services for producing different quality parts for my business. They are very passionate in every fabrication process and guided me throughout the production.”

Lailafrom U.K

Lailafrom U.K“KDM has the best sheet metal fabrication services. I had the widest options of sheet metal materials at KDM. I have received high-quality sheet metal parts for my hardware. Thank you!”

Markfrom Hongkong

Markfrom Hongkong“KDM has the best sheet metal fabrication services. I had the widest options of sheet metal materials at KDM. I have received high-quality sheet metal parts for my hardware. Thank you!”

Lailafrom U.K

Lailafrom U.K

Related Resource

NEMA Rating for Electrical Enclosure

NEMA Rating for Electrical Enclosurevery electrical enclosure is designed to meet specific safety, protection and environment standard. It is the NEMA ratings that outline these critical standards in the electrical enclosure manufacturing.

Guide to Electrical Enclosure Materials

Guide to Electrical Enclosure Materialslectrical enclosure materials are available in varying grades and standards. Choosing the right electrical enclosure materials ensure durability, safety against heat, water, and other factors. Material selection impacts usage significantly.

Electrical Enclosure Manufacturing Process in 7 Steps

Electrical Enclosure Manufacturing Process in 7 StepsStop wondering how Manufacturers make Electrical Enclosures; we will expose everything about the Electrical Enclosure Manufacturing Process in easy-to-understand steps.

While there are many electrical enclosures, they are made from various materials and undergo different procedures.

Electrical Enclosure Safety

Electrical Enclosure SafetyIt’s essential to see the electrical enclosure safety precautions before choosing any of them for your systems. However, the electrical enclosures are mainly designed to protect your electrical equipment at home or workplace.