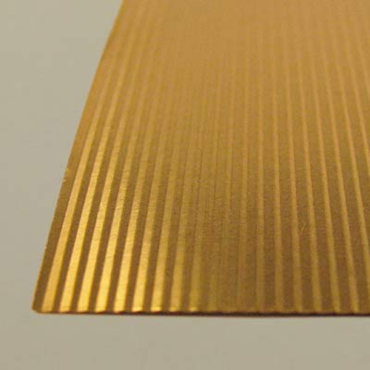

About Brass Sheet

Brass sheet is a slim, flat material crafted from brass, an alloy primarily of copper and zinc. The specific composition of brass can vary, but it typically consists of varying proportions of these two metals, with copper making up the majority of the alloy.

Brass sheets are easily cut, machined, and fabricated, allowing them to be shaped into various sizes and forms using our precision plate saws, shears, bar saws, and water jets for cutting sheets and plates to your exact specifications.

KDM-Your Exclusive Customized Solution

At KDM, we are dedicated to meeting your requirements for different sizes, thicknesses, and surface finishes.

| Thickness | 0.1~25mm |

| Grades | C26000 (Cartridge Brass), C28000 (Muntz Metal), C35300 (High Leaded Brass), C36000 (Free-Cutting Brass), C46400 (Naval Brass), C51000 (Phosphor Bronze), C68700 (Aluminum Brass), C46400 (Naval Brass), C21000 (Gilding Metal), C26000 (70/30 Brass), etc. |

| Surface finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Size | 100mm x 100mm, 600mm x 250mm, 200mm x 150mm(A5), 250mm x 250mm, 300mm x 200mm(A4), 400mm x 300mm(A3), 500mm x 250mm, 500mm x 500mm, 600mm x 500mm, 1000mm x 250mm, 1000mm x 500mm, 1000mm x 600mm, 1000mm x 1000mm 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm |

Brass Sheet Makes Your Projects Perfect

Brass sheets offer a range of features that make them well-suited for various applications, including decorative, industrial, and functional uses. Some of the key features of brass sheets include:

- Attractive Appearance: Brass sheets have a distinctive gold-like color and a lustrous finish, making them aesthetically pleasing for decorative and ornamental purposes.

- Corrosion Resistance: Brass is naturally resistant to corrosion and tarnishing, which ensures the durability and longevity of brass sheets, particularly in outdoor or marine environments.

- Malleability: Brass is a highly malleable material, which means that brass sheets can be easily formed, bent, stamped, and engraved to create intricate designs and shapes.

- Electrical Conductivity: Brass is a good conductor of electricity, making brass sheets suitable for electrical and electronic applications, including connectors and terminals.

- Thermal Conductivity: Brass has good thermal conductivity, which makes it appropriate for use in applications where heat transfer is important, such as radiators and heat exchangers.

- Ductility: Brass sheets are ductile and can be stretched or drawn into various forms without fracturing, making them versatile for manufacturing processes.

- Workability: Brass is relatively easy to work with using common metalworking tools, including cutting, drilling, and soldering, making it accessible for craftsmen and manufacturers.

- Sound Properties: Brass is valued for its acoustic properties and is commonly used in musical instrument construction due to its resonance and tonal qualities.

- Low Friction: Brass has a low coefficient of friction, which makes it suitable for use in applications where low wear and reduced friction are important, such as bushings and bearings.

- Biocompatibility: Brass is generally safe for contact with skin and is often used in jewelry, watch cases, and other items worn on the body.

- Recyclability: Brass is a highly recyclable material, which aligns with sustainability and environmental considerations.

- Antimicrobial Properties: Some brass alloys exhibit antimicrobial properties, which can be beneficial in applications where bacteria and microorganism control is important.

- Hygienic: Brass is non-porous and easy to clean, making it suitable for applications where cleanliness and hygiene are essential, such as food equipment.

Brass sheets are valued for their combination of aesthetics, corrosion resistance, malleability, and conductivity properties. These features make them adaptable for various industries, from art and design to construction, engineering, and manufacturing.

Types of Brass Sheet

Brass Sheet Applications

Brass sheets find a wide range of applications across various industries due to their unique properties, including their attractive appearance, corrosion resistance, and malleability. Some common applications of brass sheets include:

- Architectural and Decorative: Brass sheets are used for decorative elements in architecture, such as ornamental railings, door handles, trim, and fixtures, adding an elegant touch to buildings.

- Musical Instruments: Brass sheets are essential for crafting musical instruments, including trumpets, trombones, saxophones, and various percussion instruments, due to their acoustic properties and resonance.

- Nameplates and Plaques: Engraved or etched brass sheets are used for manufacturing nameplates, plaques, and commemorative markers, often seen in buildings, memorials, and institutions.

- Jewelry: Brass sheets are sometimes used as a base for jewelry, allowing for intricate designs and enameling.

- Electrical and Electronics: Brass sheets are used in electrical components, connectors, terminals, and switches due to their good electrical conductivity.

- Heat Exchangers: Brass sheets are used in the manufacture of heat exchangers for various applications, including HVAC systems and industrial machinery.

- Radiators: Radiators in automobiles and buildings often incorporate brass sheets for their thermal conductivity and corrosion resistance.

- Marine Applications: Brass sheets are employed in marine environments for their corrosion resistance, used in boat fittings, ship propellers, and nautical equipment.

- Plumbing and Pipe Fittings: Brass sheets are used for plumbing fixtures, pipe fittings, and valves due to their resistance to corrosion and water exposure.

- Clock and Watchmaking: Brass sheets are used for crafting clock dials, watch casings, and other components in horology.

- Craft Brewing and Distilling: Brass is utilized in the construction of brewing and distilling equipment, such as kettles and fermenters.

- Automotive Components: Brass sheets find use in automotive manufacturing for items like gaskets, ignition components, and decorative trim.

- Aerospace and Aviation: Brass sheets may be employed in aircraft for various applications, including parts that require corrosion resistance.

- Craftsmanship and Detailing: In woodworking and cabinetry, brass sheets are used for inlays, accents, and detailing in furniture and cabinetry.

- Sound and Lighting: Brass sheets are used in the entertainment industry to support audio and lighting equipment for concerts, theaters, and events.

- Food and Beverage Processing: Brass sheets can be used in food processing equipment and brewery tanks for their hygienic properties.

- Art and Craft Projects: Artists and craftsmen use brass sheets for a variety of creative projects, including sculptures, jewelry, and metal artwork.

- Switchgear and Electrical Panels: Brass sheets are utilized in the construction of switchgear cabinets and electrical control panels.

- Telecommunications: Brass sheets are used to mount and house equipment in telecommunications facilities, data centers, and network cabinets.

The versatility of brass sheets, along with their aesthetic appeal and functional properties, makes them a popular choice for numerous industries and applications. Their corrosion resistance, malleability, and electrical conductivity contribute to their widespread use in various manufacturing and artistic endeavors.

To anneal a brass sheet:

- Clean the sheet.

- Place it on a fire-resistant surface.

- Heat it evenly with a propane torch until it turns dull, cherry-red.

- Quench it in water.

- It will become softer and more malleable for further processing or shaping.

To bend brass sheet:

- Mark the desired bend line on the brass sheet.

- Secure the sheet in a bench vise or with clamps.

- Use a straightedge to guide the bending process.

- Tap gently along the marked line to create a crease.

- Gradually increase the tapping force to initiate the bend.

- Adjust the angle as needed, using a wooden or plastic block if necessary.

- Check the bend angle periodically.

- Complete the bend along the entire marked line.

- Double-check the angle before removing the brass from the vise or clamps.

To cut brass sheet:

- Measure and mark the cut line on the brass sheet.

- Choose an appropriate cutting tool:

– For thinner brass sheets, use a hacksaw or jeweler’s saw.

– For thicker brass sheets, use metal shears, tin snips, or aviation snips.

- Secure the brass sheet and align the cutting tool with the marked line.

- Make a clean, straight cut along the marked line.

- File the cut edge to smooth any rough spots.

- Remove any protective coating if necessary.

- Clean and inspect the cut brass sheet for accuracy.