Before choosing a titanium alloy, it is necessary to understand its grades for industrial applications!

Whether you need titanium alloy for aerospace appliances or medical implanting devices, read this guide. It will give an explanation of everything you should know about titanium alloy, its properties, grades, and applications.

Let’s move into it.

Understanding Titanium Alloy

A titanium alloy is a combination of titanium metal with trace metals such as vanadium, molybdenum, manganese, iron, cobalt, nickel, and copper. With their high density of approximately 4420 kg/m3 and tensile strength of 1000 MPA, these alloys can withstand intense temperatures.

Titanium alloys have many applications in multiple fields, from biomedical and aerospace to the car industry. All uses of titanium alloys are linked to their properties, like good electrical conductivity, biocompatibility, and corrosion resistance.

Properties Of Titanium Alloy

When titanium comes in the form of alloys, the properties of pure titanium are enhanced or lessened. Here are some:

- Density: Titanium alloys are usually hard and strong, but their density is relatively low, around 4.51 g/cm³. This combination offers them a sturdy strength-to-weight ratio and allows their usage in numerous fields.

- Tensile strength: On the besis of different grades, the tensile strength of titanium alloy ranges from 600 MPA to 1200 MPA.

- Corrosion resistance: Titanium metal alloys have sturdy corrosion resistance, due to which they’re resistant to acids or bases. These alloys even perform better in seawater in comparison to stainless steel, and copper-nickel alloys.

- Biocompatibility: Titanium alloys are matched with human tissues, consequently used in various medical implant devices. Titanium’s specific high strength and electric conductivity help its biocompatibility.

- Ease of Machining: Some titanium alloys have great formability because of their superelasticity, making them beneficial in diverse technical tasks like spinning or casting.

- High-Temperature Performance: The titanium alloy has stability at high temperatures as much as 600°C and even longevity at -196 to -253°C. Thus, it is specifically utilized in aerospace, gas mills, etc.

Grades Of Titanium Alloy

The grades of titanium display metal resistance when it comes to conductivity. Although titanium is long-lasting, when mixed with other metals, it becomes more potent. Here are some titanium alloy grades:

Grade 5 Titanium Alloy

Grade 5 is a common titanium alloy used for welding appliances due to its high conductivity. This alloy is used in home equipment, which can be stress-bearing. This alloy is used in the petroleum and chemical industries. These alloys are ideally used in environments where high performance and corrosion resistant material are required, just like in nuclear reactors.

Grade 6 Titanium Alloy

Titanium alloys of grade 6 contain aluminum and tin however are frequently used in excessive-temperature bearing environment. These alloys are specially used in airframes and jet engines.

Grade 7 Titanium Alloy

Grade 7 titanium alloy is used for low-temperature and pH environments because of its severe corrosion resistance.

Grade 11 Titanium Alloy

These titanium alloys are preferably utilized in situations where high temperatures and excessive corrosion resistance are required. Grade 11 titanium alloys are utilized in petroleum processing systems. Such titanium alloys are used in the production of turbines and liquid hydrogen storage tanks. .

Grade 12 Titanium Alloy

It applies to the manufacture of cryogenic vessels, heat exchangers, distillation columns, and other gadgets working at excessive temperatures. Grade 12 titanium alloy is ideal for the production of valves, fittings, and different opperations that need corrosion resistance.

Grade 23 Titanium Alloy

The titanium alloy grade 23 has accurate fracture longevity and ductility. It mainly works within the medical implant manufacturing industry.

Different Alloys of Titanium

As mentioned earlier, a titanium alloy is formed when titanium metal is combined with different metals, on basis of their constitution, here are a few alloys of titanium:

Titanium Aluminum Alloy

Titanium aluminum alloy is considered a high-temperature material. These alloys exhibit excessive-temperature properties like excessive stiffness, and precise yield strength. Aluminum is lightweight as well as corrosion-resistant; on the other hand, titanium is well-known for its excessive conductivity of 50,000 to 200,000 psi. The combination of these two metals comes with an excessive strength-to-weight ratio. These properties of titanium aluminum alloy permit their utilization in extensive industrial functions like:

- Manufacturing of plane structures, aero-engines, discs, and casings.

- Utilized in the production of sports equipment, which includes golf clubs, bicycle frames, tennis rackets, and many others.

- Titanium aluminum alloys are used for medical implants because of their biocompatibility.

Titanium Tungsten Alloy

Titanium tungsten alloys are formed with a combination of 9 to 20% tungsten and 99% to 80% titanium. These alloys show off outstanding properties, which include 210000 psi yield strength, hardness, heat resistance, and corrosion resistance, because of their wonderful relative strength-to-weight ratio.

- With a 1.000 MPA tensile power, these alloys can flawlessly perform high performance operations.

- Tn-Ti alloys can undergo compression operations up to 1500 MPA and are therefore used in load-bearing appliances.

- The aggregate of these alloys makes them hard enough to shape drilling appliances.

- Titanium-tungsten alloys are utilized in kitchen home equipment because of their excessive corrosion resistance and heat conductivity.

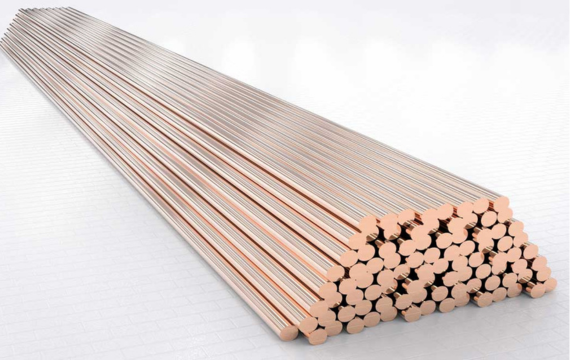

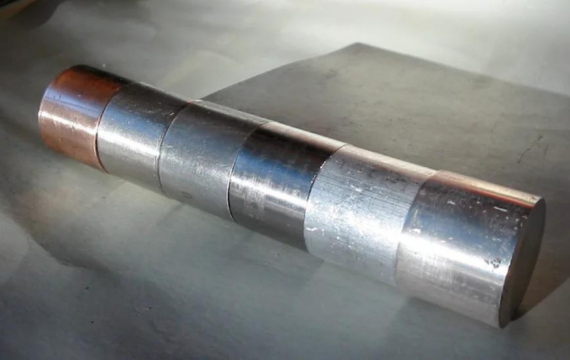

Titanium Copper Alloy

Titanium copper alloy has the main element titanium, combined with copper. These alloys have stress relaxation, high strength, and band formability properties.

- Due to their high strength, these alloys are used in connectors, smartphones, computers, or other electronic appliances.

- Titanium copper alloys are also used in the automobile industry.

- With extremely-high performance, these alloys are exceptionally conductive, therefore utilized in conductive springs, and so forth.

Titanium Iron Alloy

Titanium iron alloys are generally called ferrotitanium alloys with 10 to 20% iron and up to 75% titanium composite with other trace metals. These alloys are regularly used in powder form, where they have combined properties like hardness, conductivity, ductility, corrosion resistance, and many others.

- Steelmaking organizations use titanium iron alloys as cleaning supplies.

- Titanium is exceptionally reactive with sulfur and different elements like carbon, and nitrogen, it forms an insoluble compound and isolates them in slag.

- Titanium iron alloy, when utilized in steel as an alloying agent, will increase steel’s hardness and strength.

- Titanium iron alloys play a role in steel’s finer grain shape.

Titanium Nickle Alloy

Titanium nickel alloys are usually called nitinol compounds and feature a shape memory. When these alloys are subjected to macroscopic deformation, they instantly get back to their shape.

- Titanium nickel alloy is widely utilized in biomedical programs, car actuators, and micro-electromechanical structures.

- Archwires and root canals use these alloys for orthodontic and endodontic treatment, respectively.

Titanium Vanadium Alloy

When vanadium is selected to make an alloy with titanium, the strength of titanium is enhanced. These alloys exhibit welding and fabrication characteristics.

- Ti-V alloys are utilized in diverse programs, including radiation protection, step soldering, casting, and many others.

Titanium Gold Alloy

These alloys consist of titanium and gold. Due to excessive tensile strength, excessive yield strength and hardness, utilized in ceramics, and jewelry.

Applications of Titanium Alloy

Titanium, when combined with other elements like aluminum, chromium, vanadium, etc, form alloys. The properties of titanium alloys are improved in comparison to pure titanium. Therefore, these alloys are used for diverse commercial applications. Some applications are here:

Aerospace Industry

Titanium alloys, especially Ti-6Al-4V alloy, are used in aerospace, to make aerospace fasteners, aircraft frames, and engine compressors because of their strength-to-weight ratio.

With the use of titanium alloys, the performance of the jet engine has been enhanced by up to 45%. However, these alloys aren’t used in high temperature bearing parts especially up to 400 degrees, because of combustion issues.

Medical Industry

In titanium alloys have strong biocompatibility with human tissues and, consequently used in various medical applications. Titanium has the ability to fuse with bone, that’s why it’s utilized in gadgets like artificial joints or hip replacements.

Some alloys of titanium have superelasticity; they can’t fracture or crack.Therefore, these alloys are ideal for making surgical appliances such as forceps or scalpels. Titanium alloys are utilized in medical implanting instruments.

Electrical Industry

Titanium alloys have high heat, electrical conductivity, and corrosion resistance, therefore used in the electrical industry. Electronic applications may include connectors in batteries.

Chemical Industry

Various titanium alloys are used in chemical industries like steel formation. These alloys form an inert ceramic layer, making them highly demanded in corrosive chemical plants. Usually, titanium alloys are used in an oxidizing environment. But when titanium alloy with palladium is used in reducing the environment like acids. Due to their high-temperature resistance, titanium alloys are used in electrolytic cells.

Fashion Accessories

Titanium alloy applications are popular in fashion accessories too. These alloy’s lightweight and durable properties make them ideal for fashion items. The wallets, belt buckles, and phone cases industries preferably use titanium alloys.

Additional Applications

Titanium alloys are also used in high-performance car exhaust systems. In nuclear power reactors that require corrosion resistance, titanium alloy plays a crucial role. In Marine engineering, titanium alloys are utilized to make pumps and Maine oil drilling machines due to their high specific strength.

Conclusion

As you can see, titanium alloy is an essential component for various industrial purposes. I hope that with the information in this guide, you can choose the suitable alloy for your industrial desires.

FAQs

Is Titanium Alloy Stronger than Simple Titanium?

Titanium is a strong metal, titanium alloy comes with equal energy and a corrosive nature with more flexibility and malleability. Therefore, titanium alloys are used in more operations than natural titanium.

Is Titanium Alloy Bulletproof?

Yes, titanium has a bulletproof or bullet-resistant nature. The army, aerospace, automotive, and marine industries regularly use titanium due to its bulletproof and bullet-resistant qualities, as well as its lightweight and warmth resistance.

Compare Titanium Alloy With Aluminum Alloy?

In the assessment of aluminum alloy, the titanium alloy’s performance is right. With their high strength-to-weight ratio, these alloys are used for big applications instead of aluminum alloys. Titanium alloys are used in aircraft and submarine appliances due to their corrosion resistance. On the other side, aluminum alloy is used for doorways and home windows.

What Are The Advantages Of Titanium Alloy Over Steel Metal?

For harsh environments, titanium alloy’s advanced corrosion resistance stands out over steel. Titanium alloy charges are less than steel, making it a famous desire for big-scale projects and packages in which price is an enormous factor.

Is Titanium Alloy Magnetic?

No, titanium is not magnetic, because it has a crystalline structure without unpaired electrons, which are required for a material to exhibit magnetic properties. This means that titanium alloy does not have interaction with magnetic fields and is considered to be a diamagnetic fabric.