Looking for a portable welding solution? I would suggest you go with MMA welding straightway.

It is an affordable manual welding process that doesn’t require any external shielding gas. However, experience is needed to run this manual process.

So, if you are a beginner and want to learn about MMA welding, this guide is for you-

What Is MMA Welding?

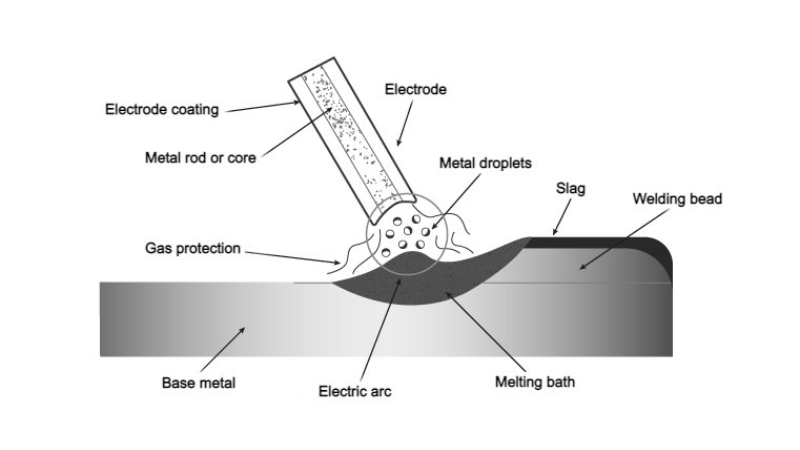

The Manual Metal Arc Welding (MMA welding) is also known as stick welding. In this process, flux-coated electrodes are used to join the metal pieces together.

Here, a welding machine forms an electric arc. This melts the electrode and the working piece, which joins metal parts on cooling.

MMA welding is cheaper because it doesn’t require external shielding gas. The flux coating of the electrode acts as a shielding gas, protecting the weld pool from contamination.

Application of MMA Welding

- Construction of bridge, building, and joining pipes

- Welding different parts of ship and automotive

- Welding metal furniture like chairs, tables, beds, etc.

- Join the pipelines of oil and gas fields

- Fabrication of heavy machinery and other manufacturing equipment

Equipment Required For MMA Welding

Welding Machine

The welding machine supplies the current required to form the electric arc. Depending on the requirements, this can be Alternating (AC) or Direct (DC). Other equipment, such as the electrode holder, electrode, and welding cables, is connected to this device.

Electrode

In MMA welding, electrodes act as a filler metal. It is coated with flux that acts as a shielding gas when heated. The most common types of electrodes used in MMA welding are as follows:

a. Basic Electrode

Basic electrodes have a coating composed of titanium dioxide (TiO2), calcium carbonate (CaCO3), and calcium fluoride (CaF2). These electrodes have a fast-freezing property that solidifies the weld quickly, speeding up the process.

Besides, basic electrodes have low hydrogen content, which makes the weld crack-resistant. E7018 is the widely used basic electrode variant used for welding heavy-duty steels in the construction of bridges, ships, etc.

When to choose?

- For medium penetration

- Faster welding speed

- Medium to heavy fabrications

- High crack-resistant requirement

- Welding challenging parent metals, e.g., thick-walled metals

b. Cellulosic Electrode

The coating of cellulosic electrodes is composed of organic materials, accounting for 30% of their coating weight. They penetrate 70% deeper than other electrodes. So, you can use them for applications that need deeper penetration.

Cellulosic electrodes like E6010, E6011, and E7010 are used in welding large-diameter pipes and maintenance works. However, the major drawback is the massive generation of hydrogen, which increases the possibility of cracking.

When To Choose?

- For deep penetration

- Vertical down welding

- For oil and gas pipeline welding

c. Rutile Electrode

Rutile electrodes are ideal for welding thin to medium-thick metals. Their outer coatings contain a high amount of titanium dioxide (TiO2); more than 95%.

They create a smooth arc and a neat weld finish. Besides, removing slag and working with rutile electrodes is also easy.

When To Choose?

- For horizontal or vertical welding position

- Medium penetration

- When you require a neat weld look

- Final passes and fillet welds

d. Metal Powder Electrodes

These electrodes contain an additional layer of metal powder that melts during welding. Different types of metal powder are used here, e.g., iron, copper, nickel alloy, aluminum, etc. They increase the metal deposition on the weld and make the joint stronger.

Compared to other electrodes, these electrodes can boost the welding speed to 130%- 140%. Besides, they offer easy slag removal and less material waste.

When To Choose?

- Fast welding speed requirements

- Robust and large-scale welding projects

- Welding thick metals

- Flat, horizontal, and vertical positions

Electrode Holder

Holding the electrode in your free hand is not possible as it conducts electricity. So, using an electrode holder is essential.

They come with an insulated handle that protects you from electric shock. This handle basically works as a bridge connecting the electrode to the power source via a cable. It also gives you greater control in positioning the electrode.

Welding Cables

The current flow between the welding machine, electrode holder, electrode, and the working piece is connected via welding cables. However, the diameter of the welding cables depends on the welding current.

For higher current flow, you need welding cables with larger diameters. The distance between the welding metal and the power source also matters here. If the distance is greater, there will be voltage drop issues. To minimize this, you need to use cables with large diameters.

Safety Equipments

In MMA welding, you have to work with electric arcs, heat, and direct fire sparks, which can cause life-threatening situations. So, for safety, use a welding mask or helmet to protect your face from heat. Also, wear fireproof clothing and safety footwear.

How To Do MMA Welding? – Learn The Process

Step 1: Connecting the Equipment

The welding machine is connected to two wires—the welding cable and the return cable. The welding cable joins the electrode holder to the power source, while the return cable connects the working metal to the power source. Thus, it forms a complete electrical circuit while welding.

Step 2: Creating an Electric Arc

As you bring the electrode close to the working metal, the current flowing from the power source forms an electric circuit. This generates sparks as you take the electrode at a certain distance. The heat of the sparks melts the electrode and the metal piece.

Step 3: Electrode Adding Filler Metal And Creating Slag Layer

The molten electrode adds filler metal to join metal pieces together. The electrode’s flux coating also melts, forming a shielding gas that protects the weld from atmospheric contamination. As this gas mixes with the weld pool, it forms slag. It is a non-metallic byproduct produced by reacting with the surface of the molten metal and atmospheric impurities.

Step 4: Slag Removing

On cooling down, the slag settles at the top surface of the metal joint. You must remove this slag using a hammer, needle scaler, or wire brush. This will bring out a neat weld.

However, if one electrode is not enough and you need to add more, you must remove the slag before adding the next electrode.

Advantages of MMA Welding

Versatile Application

MMA welding techniques allow you to weld different metals like iron, aluminum, steel, etc. Besides, you can use this on thin and thick metal sheets, making the process ideal for welding in construction projects, automobiles, furniture, and more.

Portability

MMA welding requires no bulky equipment. It only deals with a welding machine and electrode, which can be easily carried anywhere. This adds portability to MMA welding.

Cost-effective

The equipment for MMA welding is cheaper than that used in other welding processes. You can also use the same welding machine for both small and large-scale production. So, you need not invest in new machinery as you scale your production. Again, no external shielding gas is needed in this process, which saves you money. All these facts make MMA an affordable welding option.

Suitability for Thick Materials

MMA welding supports deep metal penetration. So, it is a process to choose if you are working with thick metals.

Disadvantage of MMA Welding

Slower Process

As MMA welding is a manual process, it is slower than other automated methods like- MIG or TIG welding. Here, changing the electrode, removing the slag, and other processes consume a lot of time.

Requires Professional Skill

MMA welding requires professional skills. You must learn to maintain arc stability using accurate arc length and welding angle. Handling electrodes is also challenging for beginners.

Difficult To Weld Thin Metals

Controlling the heat generation of MMA welding is difficult. The high heat from the welding can deform or burn thin metal sheets. So, as a beginner, ensure the thickness of the metal must be at least 1.6mm.

Slag Removing Hassles

Slag removal is an additional step in the welding process. After the weld pool solidifies, slag is formed, which you need to remove using wire brushes.

Basic Things To Know About MMA Welding

Before attempting MMA welding, you must have this basic knowledge about the process:

Determining Welding Current

The welding current requirements depend on the diameter of the electrode. You will find this information in the manufacturer’s specifications for the electrode. However, here are the general current requirements for varying electrode sizes:

| DC Electrode Diameter (mm) | Min Current (amp) | Max Current (amp) | Average Current (amp) |

| 1.6 | 25 | 45 | 40 |

| 2.0 | 34 | 65 | 50 |

| 2.5 | 50 | 90 | 90 |

| 3.2 | 60 | 130 | 115 |

| 4.0 | 100 | 180 | 140 |

| 5.0 | 150 | 250 | 200 |

| 6.0 | 200 | 310 | 280 |

Arc Length

While welding, the gap between the metal piece and the electrode is called arc length. This impacts the intensity of heat that falls directly on the metal piece. The thumb rule is to keep the length 0.5~1.0 times larger than the diameter of the electrode.

Arch Temperature

The arc temperature for MMA welding ranges from 2700–5500°C. A short arch length generates more heat, which is ideal for deep penetration. Again, for low penetration, you must go for a long arc length, which produces limited heat.

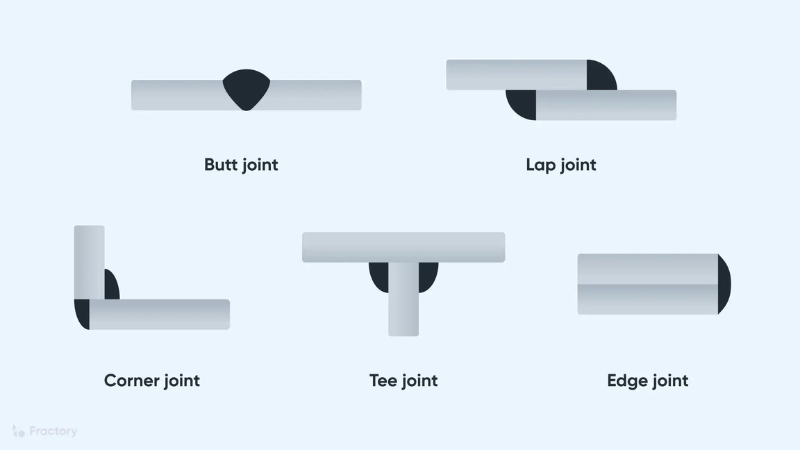

Work Angle For Different Welding Joint Types

Welding joints can be of different types, e.g., T-joint, butt joint, and lap joint. You must hold the electrode at a particular angle to achieve these joints. The chart below shows you the work angles for different welding joint types:

| Joint Type | Join Angle | Work Angle |

| T-joint / Fillet Joint | 90° | 45° |

| Butt Joint | 180° | 90° |

| Lap Joint | 90° | 60°/70° |

Welding Position

The welding speed and voltage depend on the welding position. You need to consider whether you are wielding against or toward gravity. For example, in a flat position, welding is easy as you are doing it toward gravity. This position is best for the beginner or learning stage.

However, in a vertical, horizontal, or overhead position, you are welding against gravity. So, in this process, you must increase the traveling speed to ensure the weld pool doesn’t drip over. This further requires lowering the amps rating and maintaining a tight arch throughout welding.

Travel Angle

Travel angle refers to the angle at which the electrode is moved to run the welding process. For example, if you are doing T-joint welding, keep the electrode at 45 degrees at the joint’s place. Now, slightly hold the electrode holder at 10° to 15° and pull it.

Tips For Beginners Conducting MMA Welding

1. Use the Correct Current Setting

In MMA welding, you need to apply high current and low voltage. The current can be either AC or DC. But remember, not all electrodes support AC. So, check the manufacturer’s specifications before connecting the electrode to the power source. However, the amount of current also depends on the size and type of electrode you use.

| MMA Welding Current & Voltage Requirements | |

| Current | 50-350 Amps |

| voltage | 10-50 Volts |

2. Maintain Constant Travel Speed

The speed of travel determines the penetration depth. Slow the speed of travel for deeper penetration. Traveling faster will penetrate less.

Whatever speed you choose, you must maintain consistency to ensure even welding.

3. Clean The Surface

Before you start welding, make sure the metal is clean. Don’t run the electrode over rusted metal; this will contaminate the entire joint. Instead, use a wire brush to remove the rust or unwanted materials from the working metal. This will result in polished and contamination-free welding.

4. Store The Electrode In a Dry Place

It is essential to keep the electrode in a dry place, especially when using basic or low-hydrogen electrodes. Excessive moisture will damage the electrode, and the welding will not be perfect.

5. Run A Test Welding

If you are a beginner, don’t directly run the welding on the workpiece. Instead, do a test welding on some other metal piece. Learn the angles and position and keep a constant arc length and speed. This will help you do the welding on the workpieces easily.

Wrapping Up

So, MMA welding is a slow process that works great for thick metal welding. Learn about the different welding joints and welding angles required for them. Also, ensure proper current setting, arch length, traveling speed, and distance.

Lastly, don’t forget to take safety measures to protect yourself from the heat and fire sparks of welding.

FAQs

What is the difference between MMA and MAG welding?

MMA is a manual welding process using flux-coated electrodes. In contrast, the MAG method uses wire electrodes and is an automatic process.

Do you push or pull when welding MMA?

As MMA welding produces slag, you should always use the pull technique. The electrode will get stuck in the slag if you push it.

What are the other names of MMA Welding?

MMA welding is also known as stick welding and SMAW welding.

Does MMA welding require gas?

No, MMA welding doesn’t require gas; the flux coating on the electrode produces shielding gas.