Introduction to Grinding

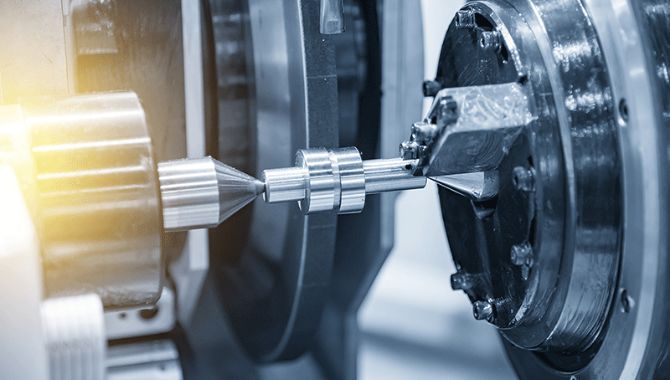

The process of removing material from the workpiece is called Grinding, it is one of the important operations in the manufacturing process. It is vital in attaining high accuracy and fine surface finish, especially when dealing with metals. Grinding therefore can and should be used to improve the quality of a product; as a result, it needs to be integrated into any manufacturing process.

Business Benefits of Grinding

Here are a few of the key advantages of grinding in your manufacturing process:

- Increased product quality: Grinding is an accurate method and delivers good results, therefore there are few defects or flaws during the production of products, leading to smooth surfaces.

- Reduction of cost: It reduces production costs as well as waste material and re-runs.

- Grinding increases precision: By grinding, it is possible to achieve better tolerance in this manufacturing line of developing parts with precision and quality.

- Increased Efficiency: Grinding operations can be optimized for speed and accuracy, thereby increasing the value of what comes off the production line.

- Longer Tool Life: With sound grinding practices, you get to save some of the tools and equipment from replacement or repair jobs.

Most Common Uses of Grinding in Manufacturing Workplaces

Grinding is portable and can be used in any area of production and manufacturing. Here’s how it can be applied:

- Widely Used In Metalworking: It is widely used in the metal fabrication for producing tight tolerance parts such as bearings or gears. These are critical in achieving the precision dimensions and smooth finishes required for metalworking applications.

- Electronics Industry: Grinding shapes small precise parts for electronics. This process is essential for manufacturing parts that have to meet the high demands of modern electronics, and therefore the reliability factor of the finished product is paramount.

- Aerospace and Automotive: In these industries, grinding is critical in developing small parts like those used in the engines and turbines. Because they work at high temperatures and pressure, these parts must be strong and precise.

- Devices In The Medical Industry: Grinding is employed in the production of accurate parts of a medical device. It helps maintain the cleanliness and quality of these parts, which is important since they are used in medical applications.

- Sharpening The Tools: Another major use of Grinding is controlling the sharpness, and this is where grinding comes into play. Maintenance through grinding enables the tool to be in service and functional for a longer time.

How to Choose a Right Grinding Method

The best grinding method will vary widely depending on what your business needs. If you are looking to get more of a final finish you will likely want the fine, flat finishes only the surface grinding will provide these things. Cylindrical grinding can be better for things like making deeper cuts or shaping parts. Internal grinding is suitable for internal surfaces of tubes or holes.

Bench grinding: Its a good general-purpose tool maintenance. Take a look at what your needs are in speed, tolerance and material type you cut. Using the right mechanism of grinding adapted to the nature, size and amount of work you have will give better results.

Safety Considerations in Grinding

When it comes to ensuring safety in grinding operations, there are several key practices you should follow:

- PPE (Personal Protective Equipment): And once again it is important to stress on the fact that before your employees get to work they should have on proper personal protective equipment some of which could be; eye protection glasses and hand gloves. This gear is very essential in protecting them from flying and sharp objects in a bid to reduce on incidences of mishaps.

- Machine Maintenance: It is pertinent to always do a check on the grinding machines and make sure that they are well serviced. Maintenance prevents accidental situations resulting from mechanical failure or fault that would otherwise have been occasioned by the wearing out of equipments. The preparation therefore implies that equipment has to be well maintained for them to function to the expectation and without any challenge.

- Operating Procedures: Operational measures of business shall embrace efficiency and security measures. Ensure that the work pieces are adequately clamped and ensure to choose the right wheel depending on the task at hand. By so doing, you are able to reduce on such cases and ensure provision of safety at workplace to all concerned.

- Training and Supervision: It is also important to train your operators on the most appropriate manner to approach the grinding process. To ensure they are embracing all the safety measures and handling the equipment in an efficient manner probation is important. This reduces a good opportunity of crashing hence improving on the safety aspect as compared with the other car types.

- Emergency Protocols: They only have to have procedures that they need to follow in case of an emergency well defined. Make sure all its employees comprehend as to the actions to be taken in the aftermath of an event for instance how to switch-off a machine, where Medical aid can be obtained among others. This show it is almost easy to handle emergences and thereby reducing the risks which affect everyone in society when there is preparedness.

Frequently Asked Questions

What can I do to Improve the Production Quality through Grinding?

This process enhances the quality of your production since it provides a superior level of accuracy and a smooth surface. This results in the generation of correct parts and reduced errors, and you are able to produce perfect products consistently.

What Are Some Potential Issues to Expect When Grinding?

Such complications include wearing out of the wheels, vibrations, and poor alignment. To cope with these, perform periodic overhaul and adjustment of the machines. It is necessary to resolve such issues when they emerge but before they escalate to an extent that the company’s productivity is affected.

How often Should I Be Servicing My Grinding Machines?

As a rule, it is recommended to complete daily operational tests, during which you need to take a look at different components to make sure that everything is okay. However, a more detailed examination and checkups should be done every week or as recommended by the manufacturer of the machines. When machines are well maintained this means that the likelihood of a sudden failure is reduced and the machines are in a healthy state.

Conclusion

For business owners in manufacturing, grinding is not only an activity but a tool that can be used to improve the value and quality of products, cut costs and improve organizational efficiency. Through proper grinding and maintenance procedures, one can increase productivity, reduce wear and tear on the tool, and in the long run, increase profitability. To improve the grinding effectiveness, training employees and creating awareness of standard operating procedures also fosters the safety of your operations. Competition is high within the manufacturing industry, however; by optimising the full grinding potential, you will find that your business has the upper hand and will achieve more profits.