Introduction to Milling Machines

A milling machine is an equipment in manufacturing operations that is used in cutting and shaping of material such as metal, wood and plastic. It operates by moving a cutting tool around a workpiece that is held firmly in position. This process forms accurate parts and intricate designs since the force exerted is smooth and controlled. If your company or industry requires precision and accuracy, Milling machines could be your best choice.

Core Components of Milling Machines

You have to be familiar with the basic parts of a milling machine before you can operate one. Therefore, We have prepared a short list of essential core components. You can view them below:

- Base: That is the lowermost portion of the device and this indicates it’s going to keep your machine strongly on floor. It is what holds the whole vibration and dampens it, while keeping the machine stable during its operations.

- Column: Act as the base and stand upright on a column to allow lifting of vertical motion of the machine. It supports main functions that allows the movements of structure of the machine.

- Knee: This is placed on the column, supports to the table and enables its vertical movement. This change helps set the height of your piece.

- Saddle: A Saddle is placed over the knee. Following that, this moves in the X-axis direction and it is useful to place with precision of work-piece from the tool.

- Table: The table supports the object and functions in X (left), Y (right) directions. its accuracy is the key factor, it only has to make positional and machining corrections.

- Spindle: It is the part which rotates and holds cutting tool in its position and guide during an operation. The spindle ideally controls the rotational rate, which is vital in selecting proper cutting methods and materials.

- Cutting Tool: The cutting tool is a component, which removes material by doing the actual cutting. It is usually placed on a spindle. The type and form of a cutting tool have an effect on the output achieved in a machining process.

Essential Milling Machine Operations for Manufacturers

You can perform various operations on a milling machine, and all these operations are characterized by specific purposes and outcomes.

- Face Milling: This operation entails using a tool to shave the surface of a workpiece to produce a flat surface. It is used for cutting material rapidly and making other surfaces ready for a different process.

- Peripheral Milling: Peripheral milling utilizes the face of the cutter whether a flat cutting tool or a mill cutting tool. It is useful for creating slots, grooves, and contours it offers the user complete control of the structure that is being cut.

- Slotting: Slotting operation involves producing slots on a workpiece usually of a narrow width and may be used in creating keyways or grooves. This operation needs specific tools to create slot with the right size and shape.

- Drilling: Drilling is the process of making holes which could be of different sizes and could be made to different depths as well. It is one of the basic operations for making holes for fasteners or other parts which are essential during the assembly and use of the product.

- Threading: Threading involves making internal or external threads on a workpiece. This operation is required for the production of screw threads which can be used for joining two or more parts.

Safety Guidelines for Milling Machine Operation

Practical measures of safety are crucial in using milling machines in order for you to avoid all accidents.

- Personal Protective Equipment (PPE)

You should always wear safety glasses such that in the event debris and small particles of metal are thrown all over they will not harm your eyes.

- Machine Maintenance

Regular checking and inspection for signs of wear and tear are crucial.

- Safe Operating Procedures

Locked up or fixed the work piece properly so that there is no likelihood of the work piece shifting its position when the machine has been turned on.

Pros and Cons of Using Milling Machines

It is necessary for you to understand the advantages and disadvantages of the milling machines in order to make a better decision for your business needs. Pros

- Working on materials such as metals, milling machines are valued for their accuracy.

- They provide more flexibility.

- Since milling machines are versatile, you can complete several operations with just a 4. single machine and enhanced efficiency.

- They ensure correct cuts and reduces human errors.

Cons

- The acquisition cost for a milling machine is relatively high.

- These machines need professional operators who understand their numerous functions and parameters.

- Some machines regular require dedicated resources who ensure that the machines are in proper working condition.

- High maintenance cost is required.

Industry Applications of Milling Machines

Different Industries use them in various different forms. Let’s discuss them below:

1. Manufacturing Sectors: These machines are crucial for the production of parts like gears, shafts, and housings.

2. Automotive Sector: Manufacturers for example use milling machines for the development of vital power train elements like engines, transmissions and the like. These product have to sustain severe working environments, therefore high accuracy and reliability of these parts are mandatory.

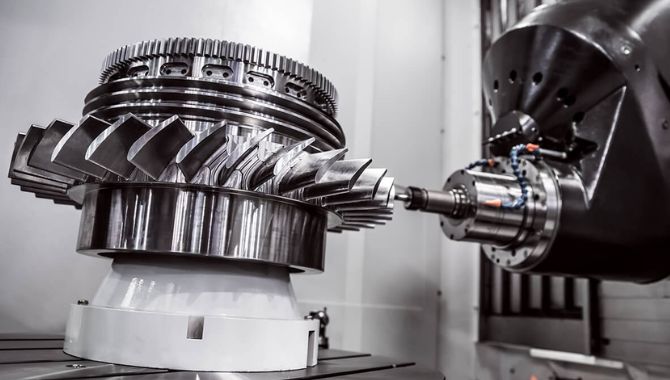

3. Aerospace Industry: Milling machines are also used in the aerospace industry for manufacturing parts with high degree of accuracy. Such things commonly include blades for turbines and gears of landing. The level of accuracy necessary in aerospace parts for safety and reliability makes milling machines crucial for aerospace applications.

4. Product Development: Milling machines are also essential in the prototyping cycle of product development. You may be able to design prototypes that must be tested and refined. Not only that, You can also improve the speed of product development and ensuing corrections and innovations.

Choosing the Right Milling Machine for Your Business

Choosing the right milling machine often depends on your requirements and uses that are to be met in the milling process.

- Vertical Milling Machines: These machines have an upright shaft or axis. The presence of shafts and axes makes them good for common tasks like boring and drilling. They are very convenient, and you can frequently employ them where the size of the work is relatively small and detailed.

- Horizontal Milling Machines: A horizontal spindle enables these machines to accommodate larger and heavier work pieces. You can use them for wide cuts as they are very good at that and are commonly employed for making big parts.

- CNC Milling Machines: CNC (Computer Numerical Control) executes the operations through programming codes in controlling the milling machines. They are very accurate and you can use them in a range of applications where high levels of repetition are required, ensuring a high level of standardization.

- Universal Milling Machines: It is a modification of the vertical and the horizontal mills and it offers versatility in use. They are versatile and can help you serve in a wide variety of operations, which makes them ideal for varied uses in machining techniques.

FAQs

How Often Should I Consider Servicing My Milling Machine?

Regular maintenance is crucial. You have to conduct day-to-day operational checks, weekly greasing and other periodic examinations as recommended by the manufacturer’s user manual.

What Kinds of Problems Are Encountered When Using a Milling Machine?

These are some of the common problems that are associated with tool wear, misaligned, and vibration. You can solve these issues as soon as possible to ensure accuracy and protect the machines.

How Many Years Can a Milling Machine Be Expected to Last?

The service life of a milling machine depends on its usage and maintenance or lack of it. Generally, You can use a milling machine for 10–20 years, according to its brand and how is it being maintained.

If you do proper servicing, keep in a well maintained environment and conduct timely repairs if needed, then this may help get the optimum use out of the equipment and increase its overall life.

Conclusion:

Whether you’re a factory manager, business owner or student, knowing the different types and applications of milling machines helps you make informed decisions to improve your business production. When used properly, a milling machine can boost productivity and enhance accuracy and efficiency.