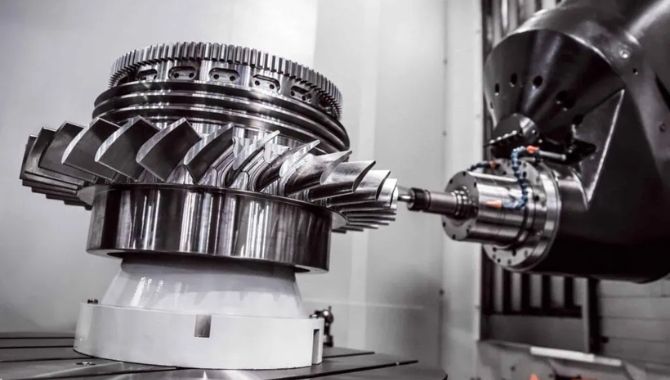

CNC machining is an important stage in many manufacturing industries. For purchasing specialists, understanding the elements that influence CNC milling costs can help them achieve exceptional practices and undoubtedly lower the normal manufacturing charges for their enterprise. There are a number of unique fees in CNC milling that, if not already managed, can add up and lead to higher costs. Acquiring machines, choosing the right materials to mill parts with cost-effective options, manufacturing and maintenance costs all continue to be difficult to turn CNC milling into a successful business. This blog will provide an explanation of the most important elements in determining the cost of CNC milling and help you make the right choice primarily for your business enterprise.

Cost Breakdown for CNC Milling

There are different categories with their respective contribution to the overall cost and you should be aware of them to make sure that your expenses do not spin out of control.

- COST OF THE MACHINE AND LABOR BEHIND THIS: The most predictable upfront cost you will have is that of your machine. Their price ranges from $50000 to 500000$ (depends on capacity, dimension of the machine as well used technologies) When you are pumping out production every day it certainly makes more sense to invest in the correct machine, but that has be weighed with dollars and other business priorities. One of the cons here is labor costs. Yes, You need right expertise for using these kind machines. The labor costs, of course, will depend largely on the project itself and what is unique about it. They will also provide you with the guaranty that these machines are properly being used and your assignments done in time.

- Overall Tooling Costs: The CNC milling needs to be carried out by using cutting tools, drills and other set of accessories necessarily. Most of the same tools are beat up and constantly in need of replacing with better steel. The cost of the tooling is vast and varied, depending on what materials are needed for a specific component], as well how much work needs to be done.

- General Material Costs: Furthermore, the type of material plays a significant role in how expensive it is going to be. A steel or aluminum product will be less expensive than a higher-end material (like titanium) which is more costly. The second group is that some materials may need other specific tools or might also have longer cycle time on the machine, which hikes up cost.

Factors Affecting CNC Milling Costs

The complete costs of a project are affected by numerous factors to be considered with CNC milling costs. All such factors should be thoroughly understood by enterprises to maximize their budgets and take data-driven decision-making. Below is an in-depth explanation of the different factors that could affect your CNC milling cost.

1. Complexity of the Design

The more complex the part is being manufactured, the longer and more difficult a job would going to be, thus increasing costs. Factors like: Number of Axes: Operating the less expensive 3-axis machine will be cheaper than a more complex 5-axis machines. Parts that have been designed with intricate features, tight tolerances or more complex geometries will generally require greater detail and effort in machining them which ultimately increases the machining time and the costs.

2. Tooling Costs

What else can drive more costs is the type and wear of tooling used during milling. The complex shapes and materials may demand specialized or custom tools that are pricier than usual tooling. Machining through harder materials can cause a tool to wear at an accelerated rate and require more frequent replacement or re-sharpening.

3. Labor Costs

CNC machines are complex and automated machinery, Programming to setup and monitoring of the machine could need a specialized person. Bearing the cost of these experienced professionals can also have an impact on the overall costs.

4. Geographic Location

There are costs associated with the machining service location that vary along labor rates and material availability, as well as overhead in different regions. While running manufacturing overseas leaves you with lower labor costs, the cost and time for shipping as well as communication issues need to be taken into account.

5. Machine Repairs and Ratings as Selected

You can expect associated overheads, including machine maintenance and energy consumption among other expenditures covered in the operating costs of the CNC facility to be factored into its overall price. Machines that are well maintained can have more efficient operation, which could reduce costs — breakdowns or outdated equipment might lead to increased cost.

Budgeting for CNC Milling

A key factor to control manufacturing costs is by developing a budget for CNC milling. This way you can easily create a coherent and sound budget and avoid any surprises with regards to the cost factors. First, costs should be predicted with a focus on materials, time spent on machines, tools, and labor. In case of doubts, you should always consult with your CNC provider for precise quotations to stick to the given budget.

Control is another factor that has to be focused on while dealing with expenditures. Reduce the cost of materials and tooling by negotiating with the suppliers for better rates. Also, ensure the maximum utilization of the machines by planning the production runs correctly and correctly maintaining the machines. These steps enable you to control costs greatly.

You should still acquire multiple quotes from various CNC service providers. So that you can compare the quotes which are given and the most effective prices for your work. And, as with any project information, you should try to be as detailed in your explanation so that the quotes are both accurate and they do not surprise good or bad. This method is going to assist in the improvement of the overall budgeting as well.

Cost Comparison: In-House vs. Outsourcing CNC Milling

Before we discuss the strategies for working with CNC milling, you have to decide whether to work with this process in-house or outsource it. Each option also has its strengths and weaknesses in terms of costs and business characteristics.

In-House CNC Milling

The major drawback of doing CNC milling in-house is that it requires a significant investment in machines, tools and labor. BUT, allows you to make changes in the production process rapidly and standardize the results. But for companies where work is coming in constantly, doing the milling in-house could be less expensive.

Outsourcing CNC Milling

It can also be advantageous when you have low-volume production and in case your manufacturing process requires specific machinery which is expensive. Outsourcing processes means fewer costly equipment installations performing the same function and maintenance. On the flip side, however, this means we will see decentralization of production and also longer delivery times as a result.

Frequently Asked Questions

How to Cut Down on the Costs of CNC Milling?

The price range of CNC milling should then be considered to the extent of how much time will a CNC mill take to do its stuff, what quantity of material becomes waste and how effective this process is. Nonetheless, if you have small workloads or particular tasks that require very precise cuts, then perhaps it would be better to outsource.

What Circumstances Can Lead to Higher CNC Milling Costs?

Anything that increases the cost of manufacturing is of importance here; this includes using costly materials, developing intricate part shapes, high time spent on setting up machines, and high wages. Knowledge of these factors will help you to better control your expenses.

How to Calculate the Cost Effectiveness of CNC Milling?

Cost-benefit analysis is the process of determining and comparing costs among all production processes. Factors such as opening hours, consumption of resources/materials, labor costs and productivity. This is to assist you in making the perfect decisions with very good value and at a low cost as well.

Conclusion

The CNC milling cost is the essential information to have in mind while choosing how much it gets to achieve a certain capacity of production. A detailed breakdown of costs also allows you to identify problematic areas, thereby highlighting opportunities for cost improvement in the actual production process. In the process of managing CNC milling (internally or externally), you wish to obtain value at the minimum possible cost. When put to use with solid strategy and tireless procedural execution, CNC milling can be a magnificent chance for you to take your production into the future and come up with formidable business consequences.