Are you considering using ASTM A500 structural steel tubing for your next project? This guide gives you important details on grades, features, applications etc. We’ll also cover comparisons to other steels and quality control to help you make better choices for your structural needs.

What is ASTM A500?

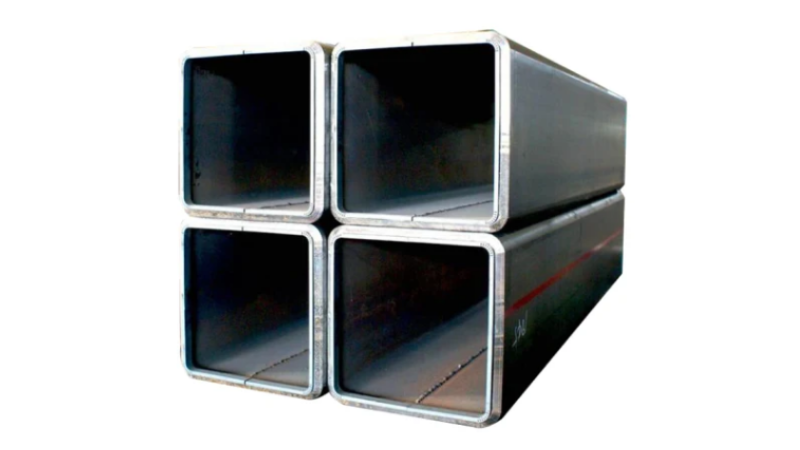

ASTM A500 is an industry standard that ASTM has published. This standard covers cold-formed welded and seamless carbon steel structural tubing. It includes many shapes like rectangular, square, round etc. This specification makes sure that quality is consistent across manufacturers which makes it easier for you to choose the best tubing for your projects.

The standard defines four grades of ASTM A500 steel tubing based on chemical makeup and strength. These grades are A, B, C and D.

It has a wall thickness of 1 inch or less than an inch. And a perimeter of 88 inches or less.

What are the Grades of A500 Steel Tubing?

ASTM A500 steel piping is available in four main categories: A, B, C and D. Each grade has special chemical makeups and mechanical properties for different structural uses. Let’s examine these grades closely:

Grade A

Grade A is the most basic A500 steel grade. It provides moderate works and strength for general structural applications. Grade A piping has a minimum yield strength of 33 thousand psi. It makes it good for projects with lower load needs.

Grade B

Grade B is the commonly used A500 grade. You will see it in many building projects because it balances formability and strength well. With a minimum tensile strength of 58 thousand psi, this grade gives reliable performance for many structural uses.

Grade C

Grade C provides higher strength than both A and B grades. This grade is perfect when more load-bearing capacity is needed. Grade C piping keeps 21% elongation in 2 inches for both round and shaped profiles which makes sure of good ductility.

Grade D

Grade D is the strongest grade in the A500 standard. Use Grade D when maximum strength is important for your structural design. It has minimum yield strength of 50 thousand psi. This makes it suitable for heavy-duty structural applications.

Comparison Table

| Grade | Tensile Strength (minimum) | Yield Strength (minimum) | Elongation (2″) Round | Elongation (2″) Shaped |

| A | 45,000 psi or 310 MPa | 33,000 psi or 228 MPa | 25% | 21% |

| B | 58,000 psi or 400 MPa | 42,000 psi or 290 MPa | 23% | 21% |

| C | 62,000 psi or 427 MPa | 46,000 psi or 317 MPa | 21% | 21% |

| D | 65,000 psi or 448 MPa | 50,000 psi or 345 MPa | 20% | 20% |

What are the Key Features of ASTM A500 Structural Steel Tubing?

This tubing has many important features that make it popular for engineering and construction. Let’s look at these features and why they matter.

Improved Structural Integrity

ASTM A500 tubing has extraordinary structural integrity from its precise chemical makeup and cold-formed manufacturing. The high yield strength, from 33 thousand psi for Grade A up to 50 thousand psi for Grade C in shaped tubing increases load capacity. Controlled manganese (max 1.35%) and carbon (max 0.26%) levels improve weldability and overall performance.

Strict Control over Tolerances

ASTM A500 has strict dimensional tolerance rules which makes sure of reliability and consistency in structures. For round tubing, outside diameter variations are within ±0.5% for sizes up to 1.900′′ (48.26mm) and ±0.75% for larger. Wall thickness tolerances stay within ±10% of the value. It guarantees uniform load distribution and integrity across the cross-section.

Broad Range of Steel Grades

ASTM A500 includes diverse shapes (round, square, rectangular) and four grades (A, B, C, D) to meet varied structural requirements. This flexibility comes from controlled alloying ingredients and manufacturing processes. For example, Grade C’s higher manganese content (0.90-1.35%) gives superior 50,000 psi yield strength in shaped tubing. The standard lets makers optimize chemical composition within set limits which allows a wide range of mechanical properties.

Standardization

ASTM A500 gives a unified framework for structural steel tubing which make sure of consistency across makers and uses. The standard carefully defines testing methods, chemical composition limits and mechanical properties. For example, it requires specific tensile testing (ASTM A370) and minimum elongation needs (e.g. 21% for Grade B round tubing). This standardization aids interchangeability, quality control and reliable engineering calculations in designs.

Performance

ASTM A500 tubing has extraordinary performance mainly for durability and load-bearing. Its high strength-to-weight ratio, with 45,000 psi (Grade A) to 62,000 psi (Grade C) tensile strengths in shaped tubing allows better structural designs. Ductility and controlled carbon equivalent requirements make sure of good weldability and formability which makes the tubing versatile for manufacturing and construction.

Applications of ASTM A500 SS Tubing

ASTM A500 widely used across many industries for its great flexibility, strength and durability. Let’s look at some important applications and why it is used:

Industrial Equipment

ASTM A500 steel tubing is a famous choice for making industrial equipment:

- Conveyor Systems: Its wear resistance and strength make it perfect for conveyor frames and supports. Grade C tubing, with 50,000 psi yield strength is usually used in heavy-duty conveyors.

- Heavy Machinery Frames: The tubing provides a strong skeleton for large industrial machines that resist heavy loads and vibrations.

- Storage Racks: Its load-bearing ability is perfect for warehouse storage and shelving systems. A single Grade B rack can hold up to 20,000 pounds per level.

Structural Applications

ASTM A500 steel tubing is widely used in structures, including:

- Support Structures: It gives reliable support for many engineering and architectural projects. Grade D tubing provides excellent weldability for intricate designs.

- Building Frames: Its high strength-to-weight ratio is perfect for making strong building skeletons. Using Grade B tubing can reduce total building weight of solid steel sections by up to 30%.

- Bridges: The tubing’s load-bearing ability and durability are very important for bridge building. ASTM A500 Grade C tubing is often used in pedestrian bridges which makes it able to support loads up to 90 pounds per square foot.

Energy Sector

In the energy sector, ASTM A500 steel tubing plays a very important role:

- Wind Turbine Towers: The high strength-to-weight ratio of tubing is perfect for making tall and stable wind turbine towers.

- Oil and Gas Pipelines: Its strength and corrosion resistance makes it suitable for moving gas and oil.

Architectural Applications

For architecture, ASTM A500 steel tubing serves both visual and functional purposes.

- Artistic Features: The tubing can create special architectural elements and artsy installations. Its high strength allows open and bold designs.

- Decorative Structural Pieces: Its flexible shapes and clean lines create visually striking structural designs. The smooth surface of tubing needs up to 20% less paint compared to rough surfaces.

Top 3 Considerations to Choose the Right ASTM A500 Tubing for Your Project

When selecting ASTM A500 tubing for your project, three important factors need careful thought. These will greatly impact the cost-effectiveness, durability and performance of your structural design.

1. Grade Selection

The grade of ASTM A500 tubing directly influences its capabilities and strength:

- Grade A: Grade A shows a minimum yield strength of 33 thousand psi. It makes it better for general uses applications.

- Grade B: It gives a higher minimum yield strength of 42 thousand psi. This allows for 27% more robustness than Grade A.

- Grade C: This grade offers a minimum yield strength of 46 thousand psi. It provides 39% more toughness than Grade A.

Studies show upgrading from Grade A to Grade B can decrease material usage by up to 20% in many structural projects which possibly cut overall expenses by 15%.

2. Shape and Size

The shape and size of ASTM A500 tubing are very important for structural efficiency:

- Rectangular: Has different moments of inertia about its axes which allows optimized designs. Rectangular tubing can cut material usage by up to 25% compared to square tubing for beams.

- Round: offers great torsional resistance and is perfect for columns. Round tubing with a 4″ outer diameter can handle up to 30% more axial load as compared to a 4×4″ square tube of the same thickness.

- Square: Gives flat surfaces for easy connections. Square tubing is preferred in 65% of framing uses because it is simple to join.

3. Supplier Selection Criteria

Picking the correct supplier is important to make sure of better quality ASTM A500 tubing:

- Production capacity: The suppliers who have higher capacity typically have 15-20% faster lead times.

- Quality certifications: Suppliers with ISO 9001 certification can reduce defects by up to 50%.

- Delivery reliability: Top suppliers maintain 95%+ on-time rates which decrease delays of projects.

- Technical support: Seasoned suppliers can give solutions to trim project costs 10-15%.

Carefully weighing these factors allows you to pick a supplier that fits perfectly to specific requirements and quality needs of your project.

ASTM A500 vs. Other Stainless Steels

● Comparison of ASTM A500 with Austenitic Stainless Steels

ASTM A500 has higher strength but lower corrosion resistance compared to austenitic stainless steel. The yield strength of ASTM A500 is 46,000 psi (Grade C). Austenitic steels like 304 typically reach 30,000 psi. However, austenitic steels are better in corrosion resistance. So they work better in harsh environments where A500 might need extra protection.

● Comparison of ASTM A500 with Martensitic Stainless Steels

Martensitic stainless steels, like 410, are stronger than ASTM A500. has The yield strength of 410 is up to 75,000 psi while A500 has 46,000 psi (Grade C) yield strength. However, A500 gives better weldability and ductility. Martensitic steels are also harder, reaching up to 55 HRC. A500 typically ranges 80-90 HRB. For general structural uses, A500 is more cost-effective.

● Comparison of ASTM A500 with Ferritic Stainless Steels

ASTM A500 and ferritic stainless steels like 430 are similar in strength. This is due to the yield strength of A500 Grade C which reaches up to 46,000 psi and the yield strength of 430′ is 40,000 psi. However, ferritic steels are better for corrosion resistance, with 430 providing up to 6 times higher resistance in mild environments. A500 is superior for weldability and formability which makes it preferable for complex structural uses. You will find A500 about 30% cheaper than 430 for general applications.

● Comparison of ASTM A500 with Duplex Stainless Steels

Duplex stainless steels, like 2205, are stronger than ASTM A500 and better at resisting corrosion. 2205 has a yield strength of 65,000 psi, while A500 Grade C has 46,000 psi. 2205 is 10 times more corrosion resistant compared to the resistance of A500. However, A500 costs less as it is typically 40-50% cheaper than 2205. A500 is also easier to form and weld, so it is better for less corrosive settings.

How to Check the Quality of ASTM A500 Structural Steel Tubing?

Make sure that ASTM A500 structural steel tubing quality meets specifications. It is very important for your project success. Here’s how to check it:

Dimension Tolerances

Use precision measurement tools like calipers and micrometers to check dimensional tolerances. Measure outside diameter in multiple spots along the tube length. For thickness of wall, ultrasonic gauges work well. ASTM A500 specifies tolerances of ±0.5% on outside diameter and ±10% on thickness walls in most situations.

Mechanical Properties

Check yield strengths and tensile using a universal tester. For ASTM A500 Grade C, expect 62,000 psi minimum tensile strength and 50,000 psi yield strength. But actual values may exceed minimums by 10-15%.

Chemical Composition

Check chemical composition through wet testing or spectrometer analysis. Look at important elements like phosphorus, carbon and manganese. For example, ASTM A500 Grade C typically allows 0.23% max carbon. Make sure composition is within ranges for each element.

| Element Name | Grade A (Max %) | Grade B (Max %) | Grade C (Max %) | Grade D (Max %) |

| Manganese | 1.00% | 1.00% | 1.35% | 1.50% |

| Carbon | 0.26% | 0.26% | 0.23% | 0.20% |

| Phosphorus | 0.04% | 0.04% | 0.04% | 0.04% |

| Sulfur | 0.05% | 0.05% | 0.05% | 0.05% |

| Silicon | 0.10% – 0.30% | 0.10% – 0.30% | 0.10% – 0.30% | 0.10% – 0.30% |

Weld Integrity

Inspect welds visually and with non-destructive methods. Use ultrasonic testing or magnetic particles to find defects. ASTM rules need sound welds without cracks, penetration or incomplete fusion. Aim for under 5% rejection rate in weld tests.

Surface Quality and Finish

Visually inspect the tubing’s surface. Check for flaws like pits, seam problems or scratches. ASTM A500 permits minor issues but limits their depth to 12.5% of the wall thickness. Use a depth gauge to measure any surface defects that you spot.

Conclusion

ASTM A500 structural steel tubing provides flexible solutions for many engineering and building projects. By knowing its grades, characteristics and their uses, you can make better choices for your needs. Remember to consider environment manufacturer quality and strength needs, when selecting tubing.

For top ASTM A500 structural steel tubing, look no further than KDM Fabrication. As industry leaders, we provide extraordinary guidance and products. Want to improve your next project? Contact us today for customized ASTM A500 tubing solutions tailored to your requirements.

FAQs

● What is the difference between ASTM A500 and A36 Tubing?

The main differences between ASTM A500 and A36 tubing are: A500 has higher strength and is specifically made for structural tubing, while A36 is a more general-purpose structural steel. A500 only comes in tubular forms but A36 comes in many shapes including bars, angles and plates besides tubing.

●Is ASTM 500 Steel Galvanized?

ASTM A500 steel isn’t inherently galvanized but it can be galvanized after fabrication to improve corrosion resistance.