East carbs focus highly on giving you high quality carbon blocks for your Steel and metallurgy manufacturing industry.

East Carb’s Carbon Blocks for Your Metallurgical Needs

East Carb stands out as a leading supplier and manufacturer of carbon blocks crafted with care and precision to safeguard machinery from disruptions, by encasing them with protective epoxy material containing MWCNTs.

East Carbs Carbon Blocks have been praised for their reduced weight and increased strength compared to other materials in the metallurgy industry. These blocks are crafted for effortless cutting and shaping to achieve a uniform surface finish that meets your specifications for custom parts production.

Our Custom Carbon Block Strength and Thickness

Our carbon blocks measure to 4.5” thick and 12x12x4.5 inches in dimensions. Our carbon blocks are known for their premium strength and high-end durability when it comes to tough graphite applications. Be it heavy-duty projects or precise machining, these carbon blocks cannot afford to compromise on quality.

Features of Our Carbon Block

Excellent corrosion resistance

Our carbon blocks resist wear and tear from aggressive slags and chemicals like Hydrochloric acid, Sulfuric acid, in steelmaking furnaces. It extends service life in converters, electric arc furnaces (EAFs), and ladles.

Resistance to molten metal erosion and melt erosion

Resist degradation caused by prolonged exposure to molten metal. Preserves the structural integrity of furnace linings.

High thermal conductivity

Important feature for high-performance furnaces. Provides superior heat transfer for operational stability, and energy efficiency.

Good thermal shock resistance

Our Carbon blocks still keep their structural strength despite constant exposure to the rapid heating and cooling cycles in EAFs & ladles. Reduces possibility of cracks and premature failure.

Oxidation resistance

Treated to withstand oxidation at high temperatures of about 3000°C. Constant durability in the oxygen-rich environments of steel furnaces.

Good anti-leakage properties

The dense structure of our custom Carbon block comes with excellent sealing properties. Prevents slag and molten metal from seeping through.

Types of Carbon Blocks

- Electrically Calcined Anthracite (ECA) Carbon Blocks: These carbon blocks mainly contain calcined anthracite. Are known for their excellent thermal and chemical properties when used in aluminum and steel smelting furnaces.

- Pitch-bonded carbon blocks: Created through the combination of carbon materials and coal tar pitch, making them a top choice. Made for blast furnaces because of their resistance against both chemical and mechanical wear.

- Graphitized carbon blocks: Created through a process called graphitization and possess conductivity that makes them ideal for use in furnaces requiring efficient heat transfer.

- Microporous carbon blocks: Are extremely low in porosity. Can withstand the infiltration of metals and harsh chemical mixtures effectively. They are commonly employed in the construction of smelting plant sidewalls and linings due to this property.

- Semi-graphitic carbon blocks: They fall within the spectrum of carbon and graphitic carbon. Exhibit thermal shock resistance. Have a strong tolerance to alkalis and molten metals.

Where Our Carbon Blocks are Needed

Our Carbon Blocks are commonly used in converters and different types of furnaces like the popular steel ladles and electric arc furnaces (EAFs). They are also needed to line the walls and key working areas of many of these furnaces.

- Aluminum tank construction: Our carbon blocks are also used in aluminum electrolytic tank construction for the steelmaking industry, enhancing its thermal conductivity.

- Electroplating industry: In the electroplating industry, carbon blocks are needed in pickling tanks and plating tanks.

- Chemical Industry: Reaction tank, storage tank and other equipment linings for chemical industry.

Our Carbon Blocks Thermal Capability

As a leading supplier, our carbon blocks are a choice among customers for aluminum smelting operations and there’s a clear reason why our carbon blocks stand out compared to our competitors. Our carbon blocks are crafted from high-quality carbon materials. They excel in handling high temperatures when used in aluminum smelting processes. With their low porosity feature and preventing metal penetration, these carbon blocks boast longevity and resilience against heat, ensuring prolonged lifespan, for sidewalls and linings.

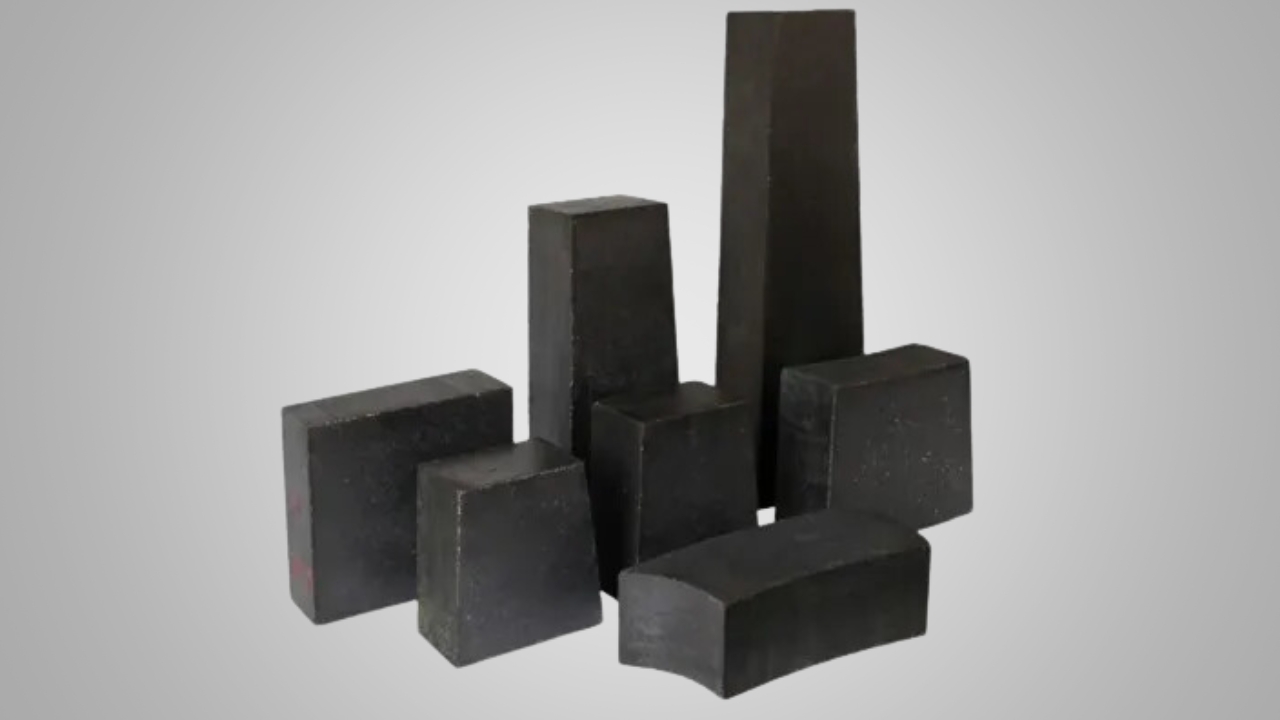

What We Offer

Due to our years of experience in the industry, our Carbon Block selection is based on high quality and superior products. At East Carb, we offer the following:

- Prebaked carbon blocks: Comes with lower pores and higher density.

- Self-baking carbon blocks: Higher electrical conductivity, lower mechanical strength and density.

- Semi-graphite carbon brick: Good thermal conductivity, lower porosity, higher density and good mechanical strength.

- Microporous carbon bricks: High porosity, good chemical stability and durability.

- Corrosion-resistant carbon bricks: Premium resistance to corrosion.

All of our carbon blocks are made with premium quality graphite and coke materials with quality control on every batch and orders.