Pipe flanges are important parts used in many industries like oil & gas and construction. They are used to join valves, pumps & pipes. They help you create a strong & secure connection. Everything stays in place.

In this guide, you will explore the various kinds of pipe flanges. Let’s dive in!

Pipe Flanges Types Based on Features

Following are the 9 different flange types utilized in pipe systems. We have also explained briefly about the usage of each type.

1. Orifice Flanges

Orifice flanges are always used in pairs. They work with an orifice plate to measure the gas & liquid flow. These flanges have pre-drilled & tapped holes in their rims. These holes allow for metering pipes.

Normally, orifice flanges are welding neck flanges. But threaded & slip-on flanges can also be used for end connections. The pipe should be drilled to fit the tapped hole so the pressure can be measured easily. With this setup, you can monitor and control the flow within the system.

2. Long Welding Neck Flanges

These neck flanges have a lot of things in common with weld neck pipe flanges. But there is one slight difference. They have an extended neck & it is not tapered. This neck is important in bore extension. These pipe flanges are used in high-pressure & high-temperature applications like oil, gas and petrochemical industries.

These flanges can match the bore size of the pipes in the system. You are free to adjust them according to your needs. They are often used as nozzles & to replace sections of pipes. They are strong enough to handle high pressures in applications like drilling rigs & pressure vessels.

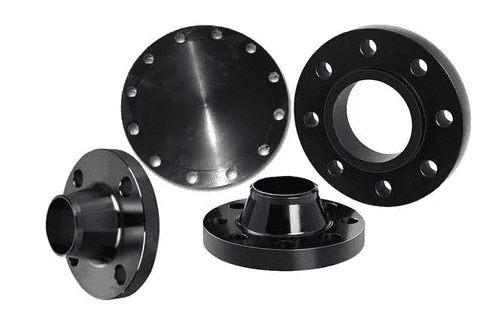

3. Blind Flanges

Blind flanges are simply solid disks without a center hole. You can also use them for closing the pipe end. They are considered caps for pipes. No fluid or gas will ever pass through them. These flanges are very strong & are able handle high pressure. So, they are perfect for pressure testing.

Blind flanges are used in many industries to stop the flow in pipes & valves. Their different styles include raised face and flat face. They are famous for being the most stressed type of flange in larger sizes. This stress is mainly the bending stress near the center.

4. Slip On Flanges

These flanges are rings. They can easily slip over a pipe end. They are actually thinner than other types & we use them in low-pressure systems. A slip-on flange is welded on its inside and outside. This thing prevents leaks and provides extra strength.

They are also super-easy to position before welding. So, their installation process is easier. These pipe flanges allow the pipe to be inserted completely through them. It results in a secure connection.

5. Weld Neck Flanges

The weld neck pipe flange possesses a lengthy & tapering neck. This design makes them very strong & reduces erosion at the place of joints. Its neck also helps to transfer stress from the flange to the end of the pipe. So, they are ideal for high-pressure & high-temperature applications.

These flanges are mostly used in pressure vessels and for creating manholes. They provide excellent stress distribution. Due to this reason, you can easily do flaw inspection.

6. Socket Weld Flanges

They are designed for small-sized & high-pressure piping systems. These systems don’t have corrosive fluids. To use them, you insert the pipe into a socket & then apply a single filet weld on its outside.

These flanges are strong & durable. Their fatigue strength is 50% more as compared to double-welded slip-on pipe flanges. If the space is limited, you can definitely use them as an alternative to weld neck flanges. However, we don’t recommend them for critical services due to the single weld connection.

7. Lap Joint Flanges

Lap joint flanges are used with a piece called a stub end. This piece slides over the pipe. These flanges are also famous with the names loose-ring flanges & back-up flanges. Their main advantage is they can be easily taken apart for cleaning & inspection purposes.

They are also durable. Their most often use case is when the pipe is made from an expensive material. Why? Because the flange will not come into contact with the fluid. It is excellent for systems that need frequent maintenance. The flange alignment is also easy because the stub end has the ability to be welded to a pipe.

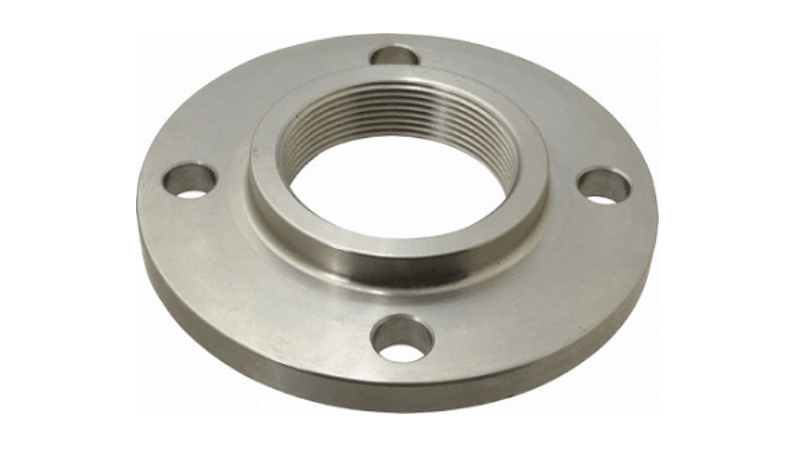

8. Threaded Flanges

These pipe flanges are also known as screwed flanges. They are used for low-pressure applications with smaller & thick-walled pipes. These flanges are special because they have threads inside. Threads assist them to be firmly screwed onto different pipes.

You can quickly install & remove them in systems where welding is not possible. Threaded flanges are mostly used for smaller sized pipes. But, their compatibility is not with thin-walled flange pipes because threading weakens the pipe.

9. Swivel Ring Flanges

Swivel ring flanges are made in a unique way. It’s a lot easier to align bolt holes between two mating flanges. It is very useful in situations like installing large diameter pipelines & offshore pipelines.

These flanges are suitable for transporting oil, gas, hydrocarbons, water & chemicals. You can also use them in petrochemical and water management applications.

A Quick Summary of Each Pipe Flange Type

| Flange Type | Description | Uses |

| Orifice Flange | Used with an orifice plate to measure flow, pre-drilled tapped holes | Measuring flow, pressure monitoring |

| Long Neck Welding Flange | Extended neck, high-pressure & high-temperature applications | Oil and gas industry, nozzles, pipe replacement |

| Blind Flange | Solid disk for sealing the end of a pipe | Sealing pipes, pressure testing, closing valves |

| Slip On Flange | Ring that slips over the pipe & is welded | Low-pressure systems, easy installation, leak prevention |

| Weld Neck Flange | Long tapered neck, butt-welded, reduces erosion | High-pressure systems, high-temperature environments, pressure vessels |

| Socket Weld Flange | Small-sized, high-pressure systems, single filet weld | High-pressure systems, small pipes, space constraints |

| Lap Joint Flange | Used with a stub end, easy to dismantle | Easy cleaning, connecting costly materials, frequent maintenance |

| Threaded Flange | Threaded inside, easy to screw onto the pipe | Low-pressure systems, small thick-walled pipes |

| Swivel Ring Flange | Facilitates alignment of bolt holes, used in challenging environments | Large pipelines, subsea/offshore pipelines |

Types of Pipe Flanges Based On Material

The type of material used in the manufacturing of a pipe flange has much to do with its overall properties, strength and use cases. Let’s see 9 more flange types according to this parameter.

10. Cast Iron Pipe Flanges

Cast iron flanges are constructed from a very hard iron type. They are extremely strong and can hold heavy loads. You can use them in places where there is a lot of pressure & the pipes need to stay in place. These flanges are not very flexible. But, they are great for stopping the leakage of pipes.

11. Cast Copper Alloy Pipe Flanges

These special flanges are made by mixing copper & some other metals. Copper is really good at not rusting. So, these pipe flanges are really good for wet places. They also conduct heat & electricity well. That’s why you can use them in various plumbing & electrical systems.

12. Large Diameter Steel Pipe Flanges

Their name is so because of the large diameter. A steel flange is very big & contains steel. They are used in large pipes because there is a need for transporting lots of water & other liquids. These flanges have the greatest strength & can handle a lot of pressure.

13. Carbon Steel Flanges

These flanges have a special type of steel which has carbon in it. This makes the steel very strong & hard. These flanges are used in many different places because they are tough. They are also useful for high temperatures and pressure applications.

They are not as good at resisting rust like other flange types. So, you have to coat or paint them for extra protection.

14. Chrome Moly Alloy Flange

Chrome moly alloy flanges contain steel mixed with different elements like chromium and molybdenum. This special mix makes them super strong to handle high temperatures. They are used in power plants & other places where the pipes get very hot. These flanges are also good at resisting rust.

15. Stainless Steel Flanges

In this flange pipe type, the steel is alloyed with chromium. These flanges are used in places where the pipes might get wet. Their applications are also at places where cleanliness is important. Examples include food factories. Stainless steel flanges are strong. Their look is also very shiny.

16. Brass Pipe Flanges

Their construction is done from combining 2 elements: Copper and Zinc. The color of Brass flanges is shiny and golden. You can use them in plumbing & decorative places due to their nice look. These flanges are durable & last a long time without rusting. They are very good conductors of heat.

17. Aluminum Flanges

Aluminum flanges are manufactured from aluminum. It is a light and strong metal. These flanges are used in many outdoor places. They are also corrosion resistant. Their applications are generally in airplanes & cars because they don’t add much weight.

18. PVC Pipe Flanges

PVC pipe flanges are produced from PVC plastic. These flanges are also very light and don’t rust at all. They are utilized in places where the pipes carry water or chemicals. Why? Because PVC is very good at resisting many chemicals. Their installation process is very easy.

Some Special Flange Pipe Types According To DN

Flange DN is an abbreviation of “Flange Diameter Nominal.” It means the nominal diameter of the pipe where the flange can easily fit in. DN is a standardized size rule for pipes and fittings. But, it’s not necessarily the actual internal or external diameter.

There are also many pipe flange types based on the different values of DN. We have discussed the following four important ones.

19. DN 25 Flange

- Outside Diameter: 115 mm

- Diameter of Bolt: 12 mm

- Total Bolt Holes: 4

- Bolt Circle Diameter: 85 mm

- Maximum Pressure: 230 psi & 72°F

- Maximum Steam Pressure: 180 psi & 300°F

20. DN 50 Flange

- Outside Diameter: 165 mm

- Diameter of Bolt: 16 mm

- Total Bolt Holes: 4

- Circle Diameter of Bolt: 125 mm

- Maximum Pressure: 230 psi & 72°F

- Maximum Steam Pressure: 180 psi & 300°F

21. DN 80 Flange

- Outside Diameter: 200 mm

- Diameter of Bolt: 16 mm

- Total Bolt Holes: 8

- Circle Diameter of Bolt: 160 mm

- Maximum Pressure: 230 psi & 72°F

- Maximum Steam Pressure: 180 psi & 300°F

22. DN 100 Flange

- Outside Diameter: 220 mm

- Diameter of Bolt: 16 mm

- Total Bolt Holes: 8

- Circle Diameter of Bolt: 180 mm

- Maximum Pressure: 230 psi & 72°F

- Maximum Steam Pressure: 180 psi & 300°F

Wrapping It Up

So, pipe flanges are important components. We use them to connect & seal pipes in various systems. Their various types include blind, lap joint, socket weld and threaded. You can control pressure & do maintenance with them. If you understand these different types well, it will help you select the right one for your needs.