Structural steel shapes are the building blocks of modern construction. They give unmatched strength and multifunctionality. From long buildings to intricate bridges, these carefully engineered parts support incredible architectural wonders.

This complete guide will guide you through the multiple types and uses of structural steel shapes. This will help professionals like you to make the best choices for their projects.

What is Structural Steel?

Structural steel is a multipurpose building material designed to be strong and to last longer. It is mainly composed of carbon and iron and is constructed into different shapes like channels, I-beams and plates. It is known for its superb strength-to-weight ratio. It has unmatched load-bearing ability and multipurpose design options and is used from towering buildings to massive bridges.

Composition

| Element | Normal Range (%) | Function |

| Iron | 97.0 – 99.5 | Base metal |

| Manganese | 0.50 – 1.70 | Boosts strength and hardenability |

| Silicon | 0.15 – 0.40 | Maximizes strength, Deoxidizer |

| Carbon | 0.15 – 0.30 | promotes strength and hardness |

| Phosphorus | ≤ 0.05 | Maximizes strength but reduces ductility |

| Copper | ≤ 0.05 | Increases corrosion resistance |

| Sulfur | ≤ 0.50 | Improves machinability but reduces ductility |

| Nickel | ≤ 0.30 | Improves corrosion resistance and toughness |

| Chromium | ≤ 0.30 | Increases corrosion resistance and hardenability |

| Molybdenum | ≤ 0.15 | Boosts hardenability and high-temperature strength |

This composition changes depending on the specific grade of structural steel.

Mechanical Properties

To understand the properties of structural steel, let’s examine its main mechanical characteristics, starting with strength

Strength: Structural steel shows high compressive and tensile strengths. It usually has a yield strength ranging from 250 to 690 MPa. Tensile strength changes from 410 to 630 MPa and this permits it to tolerate major loads without bending.

Ductility: The ductility in structural steel allows it to bend before breakage which improves safety in structures. Its ductility is quantified by percent elongation which is generally 15 to 30% for common grades.

Toughness: Structural steel can absorb a lot of energy before breaking. This is very important to prevent brittle failures in constructions and in handling sudden impacts.

Elasticity: Structural steel can bend under stress and return to its actual shape after stress. This characteristic is necessary for load bearing uses and can be measured by Young’s modulus (normally 210 GPa).

All of the above properties can be customized through heat treatment and alloying.

Grades of Structural Steel

Structural steel has many grades based on chemical makeup and yield strength. Common European grades are S235, S275 and S355 with yield strengths of 235, 275 and 355 MPa respectively.

In the US, popular grades are A36 having yield strength 250 MPa and A572 Grade 50 which has a yield strength of 345 MPa. Higher grades such as S460 or A992 have extra strength for specialized uses.

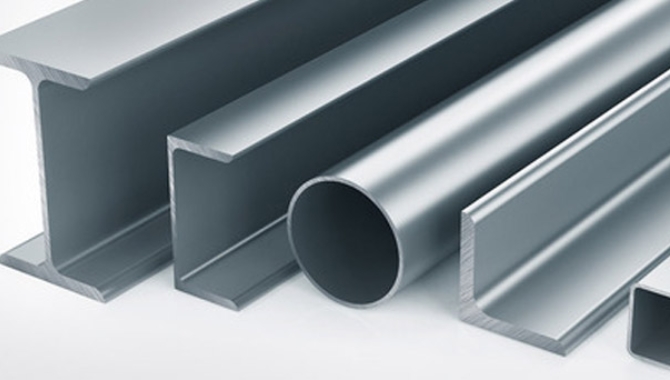

Key Types of Structural Steel Shapes

Structural steel has different shapes and each shape is designed for particular uses.

I-Beams

I-Beams are multipurpose structural steel forms, with a capital “H” or “I” cross-section. They give great strength for their weight and are mostly used in buildings where they need to support loads. I-Beams are of two types_ W and S Beams and are described as follows:

Wide Flange Beams

W Beams have a uniform web thickness and broader, parallel flanges. They give very high load-bearing ability and are commonly used in modern construction. W Beams normally have a depth-to-width ratio between 1.0 and 1.5 and yield strengths having a range from 36 ksi to 65 ksi depending on the type of grade. This gives better stability and strength for different operations.

S Beams

S Beams or American Standard Beams have an inwardly tapered flange with a 2:12 slope and even web thickness. They give great strength but are less proficient than W Beams. S Beams are mostly used in older structures and certain operations where their attributes help. The standardized dimensions of S Beams make them good for retrofit contracts.

Hollow Structural Sections (HSS)

HSS are adaptable steel profiles that have hollow cross sections. They are available in square, circular and rectangular forms. They give superb strength-to-weight proportions, usually 20 to 30% better than solid sections. HSS gives outstanding resistance towards multi-axial loading and torsion. This makes them best for beams, columns and trusses in construction. They are also used a lot in machinery and automotive industries.

Angles

Angles have an L-shaped cross-section. They are multipurpose structural steel members that are mostly used in construction. They exist in equal and unequal leg configurations. They normally range from 20×20 mm to 200×200 mm in case of equal angles, with thicknesses having a range of 3 to 20 mm. Angles give great strength-to-weight ratios and are generally used in bracing, connection and framing operations in different fields.

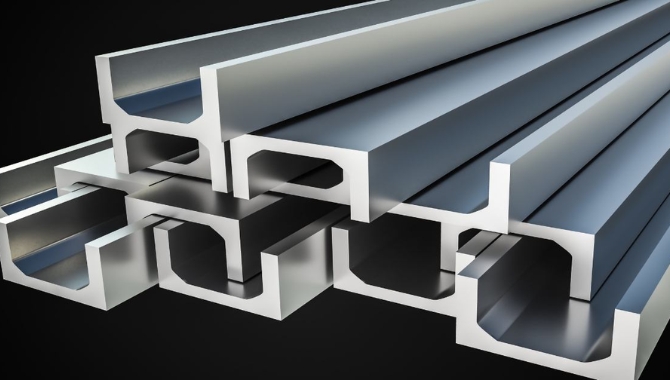

Channels or C-Beams

C Beams or channels are known for their C-shaped cross-section. These steel pieces have a normal depth of 3″ to 15″. C beams have impressive strength-to-weight ratios and resist twisting and bending well. They are broadly used for bracing, framing and providing support in different industries, particularly for equipment building and load-bearing structures e.g in transportation, manufacturing and construction industries.

Plates

These rectangular and flat pieces of steel are super versatile in construction. They come in a broad range of thicknesses i.e., from 6 mm to over 200 mm thick. They give remarkable durability and strength. Plates are necessary in ship construction, bridge building, and to combine heavy machines. They are normally used to bear heavy loads or beef up other structural parts.

Specialized Shapes

Beyond standard steel shapes, specialized profiles meet particular engineering requirements. Let’s look at some of these distinctive forms.

What are T-Beams?

T-beams are load-bearing building blocks defined by their cross-section which is T-shaped. They give best material usage and extraordinary flexural strength. T-Beams normally have yield strengths of 250 to 355 MPa for common grades. They are proficient in operations that need high bending resistance as in case of building frames and bridge supports.

What are Bearing Piles?

Bearing piles are meant to handle vertical loads. They transfer structural forces down to more stable deeper soil. They can take loads up to 2000 kN and are usually made of concrete or steel. These piles work well when surface soil is weak. They give high load-bearing strength and minimal settlement for skyscrapers, bridges and industrial buildings.

What are Bars (Round, Square, Flat)?

Bars come in flat, round and square types. Round bars can be anywhere from 6 mm to 250 mm wide. They have high tensile strength and are mostly used in reinforcement and machinery parts. Square bars usually measure 10 to 150 mm. They resist twisting well and find uses in architectural structures. Flat bars can be 3 to 40 mm thick and 10 to 200 mm broad. They are best for bracing and framing.

Benefits of Using Structural Steel

Structural steel is not just another building material. It offers a range of advantages that set it apart.

Speedy Construction: Structural steel promotes quick on-site assembly. Standard connections and already prepared parts contribute to best on-site erection. This finishes projects faster and reduces labor costs.

Service Integration: Steel structures make it easier to integrate HVAC, plumbing and electrical distribution. This reduces building height and operating expenses while maximizing performance.

Strength and Safety: Structural steel’s high strength in contrast to its weight gives strong and earthquake-resistant constructions. Its fire-resistant coatings and non-flammable nature boost building safety. This lowers the insurance expenses.

Design Flexibility: Architects use multifunctionality of structural steel to design creative and open spaces. Its ability to span long distances encourages column-free interiors which allows future changes and different architectural visions.

Sustainability: Structural steel greatly reduces construction waste with a recycle rate of over 90%. Its low maintenance and durability result in longer building lifetimes. This promotes sustainable building practices.

Conclusion

Structural steel shapes give unmatched multifunctionality in modern buildings because of their high strength-to-weight ratio, sustainability and design adaptability. From I-beams to hollow sections, these profiles allow durable and affordable structures. Structural steel continues being the foundation of new architectural and engineering solutions globally.

If you are looking to fabricate any type of structural steel, then contact KDM. We have more than 10 years of fabrication experience and can help you select the most appropriate shape for your project.

FAQ’s:

How do different structural steel shapes affect load distribution in a building?

Different structural steel shapes handle loads in their own way. HSS is outstanding under compression, I-beams outshines in bending and angles give awesome lateral support. This increases strength and stability for the whole building.

What factors should be considered when selecting a structural steel shape for a project?

Key factors to select when picking structural steel shapes are load-bearing capacity, weight, cost-effectiveness, how simple they are to fabricate, corrosion resistance, span requirements and visual appeal in the design. Engineers also need to check local building codes and the particular structural needs of the project to assure safety and top performance.

How does the recyclability of structural steel contribute to sustainable construction practices?

98% recycling rate and 93% recycled content of structural steel greatly cut down on raw material needs and energy use. Its ability to be repurposed or reused without losing quality promotes circular economy ideals. This minimizes waste and environmental damage in construction projects.