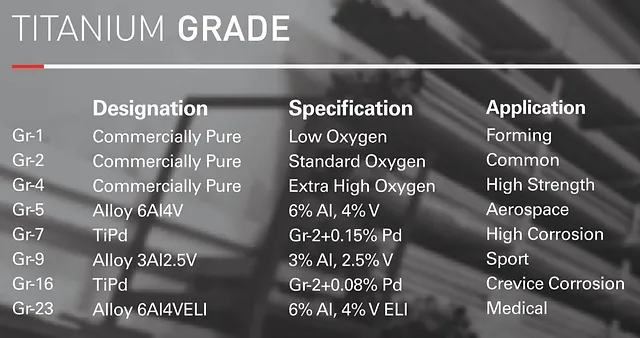

Titanium grades are broadly categorized as commercially pure titanium or titanium alloys from which you can make an appropriate selection.

When selecting a titanium grade, consider its intended application, application conditions and part description.

Categories of Titanium Grades

Commercially Pure (CP) Titanium Grades

Commercially pure titanium contains no alloying elements, with four principal grades available. The difference in these grades is brought about by the impurities present in the titanium. This typically denotes hydrogen, oxygen, carbon, nitrogen, and iron content.

Grade 1

This grade is the most ductile and softest among commercially pure titanium grades with the least yield strength. However, Grade 1 titanium is highly formable making it ideal in a diverse range of applications. It primarily contains over 99.5% of titanium with minimal impurities composed of interstitial elements. The impurities influence mechanical properties like ductility and corrosion resistance.

Properties

- As the most ductile CP titanium grade, you can easily form it into desired shapes without cracking or breaking.

- Displays high corrosion resistance even in vulnerable environments like marine conditions.

- Has balanced mechanical properties, suitable for a diverse range of applications owing to favorable formability.

- Its low density makes it ideal where weight is a critical aspect such as in aviation and medical applications.

- The weldability of Grade 1 titanium is compatible to a diverse use of techniques allowing fabrication of complex structures.

Applications

- Its exceptional chemical resistance allows use in chemical processing plants making reactor vessels, piping systems and heat exchangers.

- Grade 1 CP titanium’s corrosion resistance makes it effective in marine applications such as in desalination plants and making marine equipment.

- Medical application of this titanium grade includes making implants and surgical equipment owing to titanium’s biocompatibility.

- The weight advantage of grade 1 titanium allows usage in the aviation industry making engine parts and airframes.

Grade 2

Another common grade, this titanium variant is popular for its formidable mix of corrosion resistance, strength and ductility. While still over 99% titanium, it contains marginally more iron and oxygen content than Grade 1 titanium. It therefore displays significantly higher strength in comparison.

Properties

- Like other titanium grades, Grade 2 titanium has an impressive display of corrosion resistance across different environments.

- Besting Grade 1 titanium in strength makes Grade 2 titanium the go to material in case you desire strength performance.

- Owing to its strength, its ductility pales in comparison to Grade 1, but still enough to allow good formability even when cold-worked.

- Grade 2 titanium responds well to standard welding techniques making quality weldsuseful in fabrication of complex structures.

- Similar to other CP titanium grades, this particular grade is biocompatible allowing safe use inside the human body.

- Portrays low thermal conductivity useful where thermal stability is desirable.

Applications

- Making infrastructure in harsh chemical conditions such as chemical plants.

- Offshores drilling platforms for oil and gas extraction.

- Engine parts and components for aircrafts and hydraulic systems.

- Surgical instruments, implants and dental devices.

- Power generation infrastructure and equipment like heat exchangers and condenser tubes.

- Structural components in architectural productions.

- Engine components and parts for high-performance vehicles.

Grade 3

Grade 3 displays better strength performance than Grades 1 and 2. It however is still resistant to corrosion with good formability. The oxygen content in Grade 3 exceeds that of the earlier grades hence the strength display.

Properties

- Grade 3 titanium is resistant to corrosion induced by different environments like industrial, chemical and marine.

- The strength performance of Grade 3 titanium beats that of Grades 1 and 2.

- Owing to the increased oxygen content, the ductility of Grade 3 titanium is lower than that of Grades 1 and 2. It is, however, still formable in a variety of applications.

- This titanium grade is biocompatible elicits no reactions when in contact with biological tissues.

- The weldability of Grade 3 titanium allows its use in fabrication works requiring lots of joints.

Applications

- Its high strength and corrosion resistance allow use in chemical handling systems such as industrial plumbing.

- Where weight and strength are ideal like in aircrafts, Grade 3 titanium is an ideal material for parts can components.

- Grade 3 titanium can be used for prosthetics, implants and other medical equipment due to its biocompatibility.

- Equipment and machinery use in power generation.

- Premium and high performance vehicle parts like engine components.

Grade 4

Among the four principal CP grades, Grade 4 titanium exhibits the greatest performance in strength. Elevated strength doesn’t come at the expense of other properties, as they offer great corrosion resistance and ductility.

Properties

- Grade 4 titanium has the highest oxygen content of the commercially pure grades making it significantly stronger.

- It displays reliable resistance to corrosion like other titanium grades across different environments.

- Retains decent ductility albeit lower than other CP grades allowing formation and shaping.

- Easily weldable using techniques like gas welding.

- Biocompatible allowing internal body usage.

- Low thermal conductivity effective in high temperature applications.

Applications

- Used in orthopedic applications, as implants and surgical instruments.

- Making engine parts and components for aircraft and high performance vehicles.

- Industrial usage including machinery and equipment with chemical interaction.

- Marine applications such as water-based systems and structures.

- Power plant components such as nuclear fixtures owing to corrosion resistance and thermal tolerance.

Titanium Alloy Grades

These grades are formed by combining titanium with other metals usually one or more. Some of these metals include palladium, tin, manganese, vanadium, cobalt, manganese, chromium, nickel and copper. Alloying titanium allows you to enhance particular characteristics.

Grade 5

Grade 5 is the go to grade for applications utilizing titanium alloys. It is also referred to as Ti-6Al-4V, depicting its elemental constitution. It combines about 90% titanium with 6% aluminum and 4% vanadium, significantly enhancing its mechanical properties.Aluminum reduces the material’s density while increasing its strength and vanadium stabilizes the material’s crystal structure.

Properties

- Grade 5 titanium exhibits superb strength relative to weight far superior to commercially pure titanium grades.

- Superb corrosion resistance across different environments making highly durable.

- Displays capable strength against fatigue essential where cyclic loading or stress application is experienced.

- Retains the biocompatibility of pure grades.

- Demonstrates thermal stability at high temperatures maintaining its mechanical properties.

- Responds well to welding under precise conditions and control to prevent defects owing to sensitivity to impurities like oxygen at high temperatures.

Applications

- Making structural components for aircraft like rotor hubs, engine parts and landing gear.

- Used for bone screws and load-bearing body implants like knee joints and hip bones as well as dental applications.

- Fabricating exhaust systems and connecting rods for automotive use.

- Underwater connectors in marine vessels, fasteners and propeller shafts.

- Sporting goods like high-performance bicycle frames and golf clubs.

- Industrial use making pressures vessels, piping conduits and heat exchangers.

- Nuclear reactor parts and equipment and turbine blades in power plants.

Grade 6

Also referred by its elemental constitution Ti-5Al-2.5Sn, Grade 6 titanium is an alpha alloy. As an alpha alloy, it contains mainly elements stabilizing titanium’s alpha phase. It constitutes about 92.5% titanium, 5% aluminum and 2.5% tin.

Properties

- Has improved oxidation resistance and strength thanks to the addition of aluminum.

- Better toughness and stability at high temperatures thanks tin.

- Forms welds easily allowing fabrication of high performance parts.

- Exhibits corrosion resistance albeit to lower capability than pure titanium grades.

- Demonstrates balanced strength and ductility adequate for certain applications.

- Grade 6 titanium has good fatigue resistance especially against cyclic loads.

Applications

- Effective in making heat shields and components in high temperature environments like aircraft engines.

- Fabricating materiel for naval craft like ships and submarines.

- Chemical processing equipment and infrastructure.

- Energy equipment and parts like nuclear reactors, turbine blades and heat exchangers.

- Turbocharger parts and other engine components as well as exhaust systems.

Grade 7

Similar to Grade 2 CP titanium, Grade 7 titanium contains small amounts of palladium enhancing its corrosion resistance performance. This is especially against environments with high chloride levels and acid concentrations. Titanium is usually at about 99.2% with palladium ranging between 0.12% to 0.25%.

Properties

- Resistance to virtually all forms of corrosion is vastly improved owing to the addition of palladium.

- Offers decent balance in mechanical properties especially strength and ductility.

- Can be worked by welding without much difficulty.

- Retains pure titanium’s biocompatibility remaining passive when interacted withbiological tissues.

- Possesses low thermal conductivity allowing use in high temperature situations.

Applications

- Fixtures used in highly corrosive environments like chemical industries and desalination plants.

- Industrial equipment like evaporators and condensers.

- Equipment and infrastructure used in and around sea water.

- Aircraft framing components and fixtures.

- Medical implants and surgical implements.

- Components in geothermal and nuclear plants.

Grade 9

Also identified as Ti-3Al-2.5V thanks to its composition of about 94.5% titanium, 3% aluminum and 2.5% vanadium. Grade 9 titanium is a popular alpha-beta alloythanks to its strength, lightweight, and corrosion resistance qualities.

Properties

- Displays higher strength and hardness owing to the addition of aluminum and vanadium relative to weight than CP grades.

- Exhibits excellent corrosion resistance in different environments, such as chemical processing and marine settings.

- Grade 9 offers you better ductility in comparison to Grade 5, making it more formable and workable especially when cold working.

- You can weld Grade 9 titanium like other titanium alloysusing standard techniques without hampering material characteristics.

- This titanium alloy’s fatigue resistance is essential where stressing is rampant and cyclic loading.

Applications

- Fuel tanks, hydraulic tubing and structural components in aircraft and spacecraft.

- High-performance components in vehicles like connecting rods, valves and exhaust systems.

- Sports goods such as golf clubs and bicycle frames.

- Marine fixtures, hardware and components like propeller shafts.

- Parts for chemical plants and related infrastructure.

Grade 12

Grade 12 titanium implements minor molybdenum and nickel amounts in its composition to enhance mechanical properties like strength and corrosion resistance. Titanium is usually at about 98.7% with molybdenum not in excess of 0.4% and nickel at most 0.9%.

Properties

- The resistance to corrosion exhibited by Grade 12 titanium is excellent especially in presence of reducing and oxidizing acids. e.g. chlorides.

- CP grades, especially 1 and 2, pale in strength comparison to Grade 12 favored where strength and corrosion resistance are desired.

- You can weld Grade 12 titanium without much difficulty and without affecting the material’s parent properties.

- Even with its higher strength display, Grade 12 titanium is still ductile allowing successful formation and fabrication.

- Its thermal stability is sufficient to tolerate high temperature environments and applications without its properties deteriorating.

Applications

- Industrial plumbing infrastructure, reactors and heat exchangers in industrial plants.

- Marine application extending to parts, equipment and infrastructure.

- Components used in high temperature conditions and corrosive environmentsin power plants.

- Parts and equipment in desalination plants.

- Aircraft structural elements, hydraulic systems and fuselage.

Grade 19

This metastable beta alloy is also denoted as Ti-3Al-8V-6Cr-4Zr-4Mo describing its elemental composition. Ideally, it constitutes 75% Titanium, 3% Aluminum, 8% Vanadium, 6% Chromium, 4% Zirconium and 4% Molybdenum. The alpha phase is stabilized by aluminumwhile the beta phase is reinforced by the other alloying elements.

Properties

- As a metastable alloy, Grade 19 titanium displays great strength especially yield and tensile strengths

- The use of aluminum, chromium, molybdenum, vanadium and zirconium in this alloy greatly enhances its resistance to corrosion

- Even with its great strength, the ductility of Grade 19 titanium is sufficient to allow shaping and forming.

- You can heat treat Grade 19 titanium using processes like solution treatment and aging to further improve its mechanical properties

- The fatigue resistance displayed by Grade 19 titanium alloy is formidable enough to support cyclic loads.

- You can weld Grade 19 titanium but under special conditions to prevent the loss of core mechanical properties

Applications

- Landing gears in airplanes alongside diverse elements of their structures like fasteners

- Under sea infrastructure and marine equipment, components and hardware

- Chemical reactors and heat exchangers

- Geothermal plant infrastructure, machinery and equipment

- Suspension systems, exhaust systems and engine components in high-performance vehicles

Grade 23

The difference between titanium alloys of Grade 23 and Grade 5 is the interstitial elements quantity. For this reason it retains the same elemental composition with 6% aluminum and 4% vanadium, denoted Ti-6Al-4V ELI (Extra Low Interstitial).

Properties

- Reduced interstitial elements (oxygen, carbon, iron and nitrogen)results in increased toughness and ductility less susceptible to stress cracking

- Similar to Grade 5 titanium alloy, this alloy offers excellent strength relative to its weight

- This titanium alloy grade displays admirable resistance to corrosion, ideal when expecting extended exposure to corrosive elements

- The biocompatibility of Grade 23 titanium alloy is unmatched owing to its non-toxicity and reactivity with body tissues

- Grade 23 titanium is not easily overwhelmed with fatigue-inducing loads

- Under carefully controlled conditions, welding Grade 23 titanium alloy is possible

Applications

- Grade 23 titanium alloy finds primary use in medical endeavors like producing implants owing to its biocompatibility and fracture toughness

- The fabrication of aircrafts and related parts implements Grade 23 titanium alloys to successful results.

- Industrial applications from chemicals processing, mining and energy generation utilize parts and equipment constituting this alloy

- Parts manufacturers for premium range and high performing vehicles use Grade 23 titanium

- Marine vessels and other infrastructure in contact with sea water are fabricated using this titanium alloy

Conclusion

Depending on your application, you can implement a titanium grade whose properties resonate most with your needs. Ultimately, the challenge is in achieving an ideal balance between strength, weight, thermal stability, corrosion resistance and ductility.

Related Resources:

Titanium Alloy Types – Source: KDM

Titanium – Source: WIKIPEDIA

What is Titanium – Source: KDM

What is Titanium Alloy – Source: KDM