One of the most important thing when you decide to use any material is its density.

A reason we need to explore everything about density of titanium. Besides, this will only make sense if we compare density of titanium to other metals.

Additionally, we will also explore factors affecting titanium density and uses of titanium based on the application.

Let’s dive right in:

Titanium’s Specific Density

Supposing you look at the precise density of titanium even more carefully, you learn that it is 4. 5 g/cm3. However, this may vary depending on the titanium alloy.

When you compare this number with other metals like steel, you will realize that titanium remains at the top. You will find that titanium stands-out when it comes to having greater density than other metals.

Comparison with Other Materials

Metals with a Higher Density

Metals with higher densities: for instance stainless steel density is 7.6 to 8.0 g/cm3. Mild steel has a density of 7.85 g/cm3, while lead has a density slightly higher than mild steel at 11.34 g/cm3.

These metals weigh a lot more relative to titanium; this is due to the fact that they have more mass per volume. This is particularly relevant as far as the profession that deals with weight is concerned; titanium can be used to slash the weight while keeping strength intact.

Metals with Lower Density

As you go down the list of metals with lower densities, you get to this metal:

- Aluminum density 7 g/cm3

- Magnesium density is 1.74 g/cm3.

These metals are lighter than titanium and are preferred where the mass of the equipment has to be kept to the lowest. You will find it hard to use these metals in applications where you need strength and flexibility, hence you substitute with titanium.

Implications of Titanium’s Density

As you have seen grams per cubic meters has an effect on the sturdiness and weight of titanium. One thing you get to witness from titanium’s great density is its ability to withstand greater tension because of its excellent balance in weight. This ratio is attributed by it lower density.

Factors Affecting Titanium’s Density

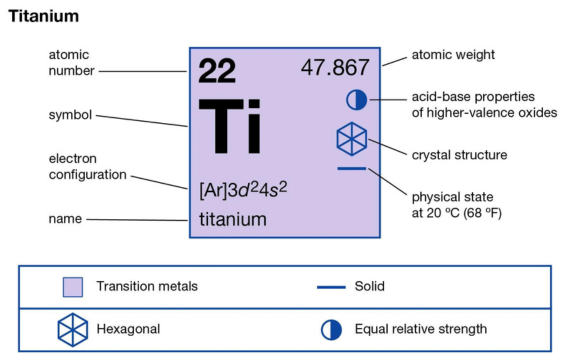

· Allotropic Forms of Titanium

This suggests that depending on the ambient temperature, titanium can crystallize in different ways. Titanium can occur in two forms depending on the environment you have subjected it to.

When you have low temperature it features an alpha titanium arranged in hexagonal atoms. On the other hand, when you place it on high temperatures it forma body-centered cubic lattice which you refer to as beta phase.

The phase change in this case can slightly alter the density since the atomic arrangement changes.

With these allotropes in mind, one can regulate the density and mechanical properties of titanium required to create parts that will be used at high temperatures.

· Effect of Contaminants and Additives

Looking at the density of titanium and the impurities, you still get to see how important the composition of the substance is. You might notice a shift in the density of titanium when you dope it by adding either aluminum or any metal that it could combine.

And at the same time make it stronger or more resistant to corrosion.

You should note that, even in small concentrations, impurities may also tend to alter the density of the material. Thus, with the proper application of control over these elements, you can obtain the desired densities of titanium.

This is to meet the specific performance criteria, besides the ability to achieve the wanted density level.

· Methods of Production and Their Impact on the Density

When it comes to processing methods, you will notice it is rather easy to grasp how the density of titanium can be controlled. Operations like forging, casting, and some of the more modern ones like additive manufacturing may alter the density due to changes in the microstructure.

For instance, porosity due to casting or 3D printing reduces density, while hot forging increases arrangement density and homogeneity.

Depending on your chosen method of destructive processing, titanium arrives at a density and performance level appropriate to its application.

Uses of Titanium Based on Density

1. Aerospace Industry

The concept of density allows for the creation of aircraft parts that are lighter but stronger and more durable, and thus more efficient and faster. This makes titanium applicable in severe conditions that include high altitudes, so that the materials experience several cases of corrosion.

2. Medical Devices

When you are dealing with implants, it very important to use items that have less density and can interact with the body perfectly. Your body normally experiences a lot tension and this makes it perfect for titanium to be used as bone replacements.

You will notice that most of the time in medical practice titatnium is widely used for hips replacement, joining bones, etc.

3. Sports Equipment

You use titanium in your sporting products for light weight, as this caters for strength and durability while in use.

Owing to this density, it is impressive since it can offer stiff yet low-density products such as tennis racquets, golf clubs, and bicycles, among others. This balance improves the user interface since it provides the needed strength without additional mass.

Conclusion

The density of titanium makes it stand-out from the rest of the metals. This is why it finds applications in crucial industry like body parts replacement and aerospace.

This means it can be used in orthopedic appliances, medical implants, and aircraft because the density is between the stainless steel and aluminum density.

More on Titanium Properties:

Does Titanium Rust – Source: KDM

Titanium Hardness – Source: KDM

Is Titanium Magnetic – Source: KDM