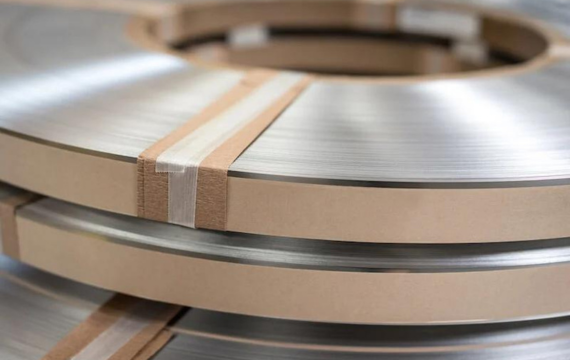

When you think about stainless steel, you most probably think of the sleek components in your car or your kitchen’s lustrous appliances.

But have you ever questioned how these pivotal appliances and components are manufactured?

Turning stainless steel into usable instruments is not the easiest of tasks but with the right machining equipment and expertise, it is doable.

What is Stainless Steel Machining?

Stainless steel machining is the metalworking process that gives you your fully formed stainless steel components, instruments, and equipment.

This includes the window frames, electrical enclosures, junction box, cabinets, and body panels in your car as well as the stainless steel sink in your kitchen.

This process gives these components their final design and dimension transforming them from a simple metal into operational equipment.

Types of Stainless Steel You Can Machine

Although at first glance you might think all stainless steel is similar, digging deeper will introduce you to the distinct types of these metals. The different types of stainless steelsare as many as 150. This distinction in characteristics is a consequence of the difference in composition. Machinable types include:

· Ferritic Stainless Steel

This stainless steel type is part of the AISI 400 Family and it thrives in the manufacturing of automotive components and kitchenware. Ferritic stainless steel became a staple in the manufacturing industry in the 1980s and its impressive magnetic attributes and corrosion resistance have made it one of the most commonly exploited metals. It comes in different grades including 409 and 430.

Properties

| Attribute | State |

| Chromium Content | 10.5 % – 30 % |

| Nickel Content | Nickel-free |

| Magnetism | Highly magnetic |

| Chemical Resistance | Very high |

| Toughness | Medium |

| Stress Corrosion Cracking | Very resistant. |

| Weldability | Low |

| Ductility | Medium |

| Heat Treatability | No |

· Austenitic Stainless Steel

You must have utilized this type of stainless steel on multiple occasions given that it accounts for the lion’s share of usable stainless steel at approximately 70%. This is primarily because you can easily weld or machine it to sculpt components with unique forms. In addition to this austenitic stainless steel boasts a high corrosion resistance but is essentially diamagnetic.

It comes in distinct grades, with the most popular grades being 304 and 316. The latter grade favors application in marine environments since it features molybdenum, strengthening its corrosion resistance. The 304 grade, on the other hand, reigns supreme in the production of kitchen appliances like sinks. It features chromium and nickel.

Properties

| Property | State |

| Chromium Content | Approximately 18% |

| Molybdenum Content | 2%-7% |

| Weldability | High |

| Heat Treatability | No |

| Corrosion Resistance | High |

| Carbon Content | <0.1 % |

| Ductility | Very high |

| Toughness | Very high |

· Duplex Stainless Steel

This unique type takes the best of austenitic and ferritic stainless steel making them your ideal metals for heat exchangers and chemical processing. Duplex stainless steel guarantees you a high resistance to stress corrosion cracking as well as corrosion. You can choose between the 2507 or 2205 grades since both exhibit high corrosion resistance. However, the 2205 grade demonstrates a first-rate resistance to pitting.

Properties

| Attribute | State |

| Chromium Content | 18% – 30% |

| Carbon Content | None |

| Nickel Content | 1% – 9% |

| Molybdenum Content | 0.1 – 5% |

| Weldability | High in the presence of nitrogen |

| Ductility | Medium-high |

| Heat Treatability | Yes |

| Toughness | High |

· Martensitic Stainless Steel

Renowned for its composition, which includes a chromium content of approximately 12-18%, this stainless steel type is exceptionally robust. This makes it your ideal machining material if you intend to produce instruments that must demonstrate a high wear resistance. Furthermore, you can elevate its hardness by simply subjecting it to heat treatment.

This magnetic stainless steel comes in two common grades namely; 410 and 420 stainless steel. The former grade favors the manufacturing of surgical instruments and kitchenware while the latter grade suits medical tools due to its rigidity and corrosion resistance.

Properties

| Attributes | State |

| Chromium Content | 12% – 18% |

| Carbon Content | 0.1% – 1.2% |

| Nickel Content | Mostly none but some have 2% – 4% |

| Weldability | High |

| Corrosion Resistance | High |

| Ductility | High |

| Magnetism | Magnetic |

| Stress Corrosion Cracking | Poor |

| Toughness | High when tempered and low when untampered. |

Advantages of Machining Stainless Steel

Choosing the ideal raw material for your machining operation is not as easy as walking your dog in the park. It requires you to carefully dissect the varying traits of distinct materials in search of desirable attributes. Stainless steel possesses most of these desirable traits, which it lends to your machining operation. They include:

- It is More Durable: Unlike other materials, machinable stainless steel can outwit harsh conditions like rust and physical pressure. This gives you finished products that can withstand the test of time.

- You Can Recycle It: By melting stainless steel scrap, you can turn worn-out equipment into raw material for your next instruments. By doing so you save on the cost of acquiring new raw materials as well as aid in environmental sustainability efforts.

- It is Hygienic: The non-porous nature of stainless steel means that there is no hiding room for microorganisms and other impurities. This means you can use stainless steel in food processing equipment.

- It is Corrosion-Resistant: During machining, you can use any coolant or lubricant without having to worry about your workpiece catching rust. You can also use its subsequent components in environments exposed to moisture.

- Forms Easily: You can perform numerous turning operations on stainless steel as long as you have the required machinery.

- Has Strong Physical Attributes: Machining operations often involve strong vibrations, which stainless steel can endure. It also exhibits a high tensile strength despite its relatively low weight.

Stainless Steel Machining Operations You Can Undertake

Converting stainless steel into the everyday items you interact with daily necessitates innovative machining operations. These operations include:

· Turning

This machining operation attempts to turn your block or formless stainless steel into a well-formed cylindrical component. You simply mount your stainless steel onto a revolving spindle, which exposes it to a sharp cutting tool that extracts the block’s exterior until a spherical shape is formed. When turning stainless steel, make certain you utilize chip breakers and coolants.

· Laser Cutting

This machining technology is taking stainless steel processing by storm thanks to its precision and reduced tool wear. It utilizes CAD software to focus the laser beam on the specific points you intend to cut or machine. However, before opting for this method, you must invest in the requisite expertise and equipment.

· Electrical Discharge Machining

You might be aware that machining stainless steel is not necessarily the simplest of tasks. This machining operation thrives in cutting and shaping workpieces known for their rigidity. All you need is high-voltage electrical pulses capable of generating intense heat that can melt metal. If you opt for this machining operation, you are guaranteed less tool wear.

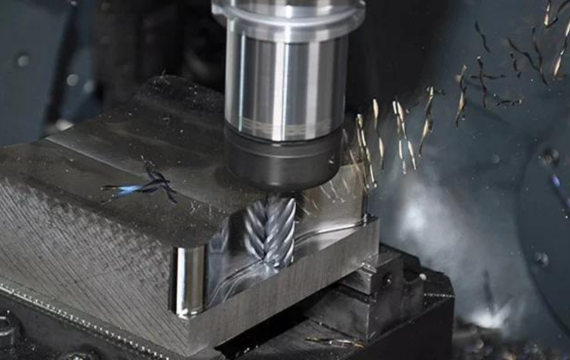

· Milling

Thanks to milling, you have enjoyed the functionality of structural components as well as intricate parts like surgical instruments. to accomplish this simple operation, simply mount your stainless steel workpiece onto your milling machine, where it will be subjected to a rotary cutter. However, you must carefully set the milling speed to avert premature tool damage.

· Drilling

If you intend to insert screw holes or holes for other fittings on your stainless steel, drilling is your ideal machining operation. You simply have to install a drilling bit on your lathe machine and position your workpiece for drilling. Drilling is primarily considered a secondary stainless steel machining operation and it requires you to use a robust drilling bit.

· Grinding

After welding or subjecting your stainless steel to another machining operation, you may realize that your final component has burrs or a rough surface. If you want to remove these burrs, you simply need a grinding tool made of wheels, which will rub off the rough surface of your stainless steel workpiece.

· Threading

When manufacturing stainless steel components that must be joined to other components using screws or fasteners, you will need to sculpt threads. For you to impart an internal or external thread on a stainless steel component like a pipe, you will need a specialized threading tool.

· Waterjet Cutting

This machining operation protects your stainless steel component from the adverse effects of heat, which can degrade your final piece’s quality. It relies on highly pressurized water to erode unwanted material from your workpiece. However, you can only utilize this method to process stainless steel grades with comparatively superior corrosion resistance.

How to Machine Stainless Steel

You cannot equate machining stainless steel, which is a unique type of metal with unrivaled toughness to machining typical workpieces like wood. To successfully machine it into a usable component, you need to follow the underlying steps:

- Planning and Preparation: First, prepare a blueprint of the machining operation you intend to undertake and the final product you intend to produce. What shape, size, and type of surface finish do you want it to bear? Once you have answers to all these questions, proceed to pick a type of machinable stainless steel for your operation

- Machine Set-Up: Now, proceed to make ready the lathe machine that will process your stainless steel workpieces. Begin by inspecting its major components to ensure they are appropriately and securely installed. Then proceed to mount the machining tool of your choice

- Machine Setting: With your workpiece and lathe machine ready, simply set the cutting parameters you want the machine to execute. For instance, if you want to thread screw holes in your stainless steel workpiece, set your desired depth of the cuts

- Coolant Application: Subsequently, pick a befitting coolant and apply it on your workpiece, particularly, the area you intend to machine. This will help avert friction and heating during machining.

- Machining: After setting your desired machining parameters, let your lathe execute your instructions. For instance, if you have mounted a drill bit and instructed your drilling machine to drill holes of a certain depth, your machine will accomplish just that

- Chip Extraction: As machining progresses, have your operators remove the chopped odd debris to avert clogging. You can use a chip breaker to ease this process or exploit highly pressurized coolants to flash out unwanted fragments

How You Can Make Stainless Steel Machining Easy

If you have ever attempted stainless steel machining, you will know it presents greater hurdles compared to machining other metals. However, with the requisite know-how, you can machine this tough metal with great ease. To begin with;

- Employ work-hardening countermeasures like cooling

- Use high-quality stainless steel that is easy to machine such as 416 stainless steel

- Select the right machining tool for the right operation

- Use a befitting Lubricant

- Use a rigid machining tool

Stainless Steel Machining Challenges

Stainless steel is undoubtedly one of the most renowned materials exploited to manufacture everyday equipment and components. However, turning it into the final products you interact with every day can be quite problematic. It comes with challenges such as:

- High tool wear

- It is quite hard

- Work hardening

- Poor chip control

- Heat generation

Common Uses for Machined Stainless Steel

Organic stainless steel boasts strong structural integrity as well as high corrosion resistance. This explains why it has continuously outwitted other metals when it comes to machining raw materials. Machined stainless steel products at present include:

- Medical instruments

- Automotive components

- Food processing equipment

- Chemical processing equipment

- Electronics

- Construction equipment

FAQs

Is it Possible to Machine Stainless Steel?

Yes. With the ideal expertise and machining tools, you can manipulate stainless steel into your desired form. However, machining it will prove to be a harder nut to crack compared to other metals or raw materials.

Which Type of Stainless Steel is the Easiest to Machine?

Stainless steel is generally more difficult to machine. However, machining different grades of this metal comes with varying degrees of difficulty. Machining the 300 grade of stainless steel is the most difficult while machining the 400 grade is comparatively easier. As easy as cutting through butter.

Can You Use Normal Turning Tools to Machine Stainless Steel?

Attempting to machine stainless steel using typical machining tools will lead to premature tool damage irrespective of the stainless steel’s grade or type. Its high toughness necessitates specialized tools such as carbide-tipped and ceramic tools.

Which is the Best Coolant to Use When Machining Stainless Steel?

There is no one-fit-all solution to the heat generation problem you encounter when machining stainless steel. When operating on a specific grade, you should pick a coolant that is friendly to that grade. However, there are soluble oils and synthetic coolants that are generally ideal for standard stainless steel machining.

Conclusion

As you can see, it is possible to make a wide range of parts and components by machining stainless steel.

At KDMFAB, we offer complete stainless steel fabrication. Whichever structure you need, KDM will fabricate the component according to your unique specifications. For inquiries, contact us now.