The reason why tin has low melting point remains a mystery to many people.

Well, this article covers everything you should know about the melting temperature of tin – let’s dive right in:

What Temperature does Tin Melt?

Ideally, tin has a low melting point. Pure tin melts at 232 °C. Or, you may also refer to this temperature as 450 °F.

Comparing Tin Melting Temperature to Other Metal Melting Point

| Elements | Melting point of metals in degrees Celsius. |

| Melting temperature of steel | 1370 |

| Melting temperature of gold | 1064 |

| Tungsten melting point | 3422 |

| Melting point of lead | 327.5 |

| Melting point of silver | 961.8 |

| Melting point of zinc | 419.5 |

Comparing the Melting Point of Tin and the Boiling Point of Tin

The boiling point of tin is slightly higher than the temperature tin melts. The boiling point is 2602 degrees Celsius.

As you can see, this is nearly 10 times the melting temperature.

Why Tin Melting Point May Vary

Some common variables affecting the melting temperature of tin are:

· Pressure

Pressure is directly proportional to tin melting temperature.

· Impurity

Impurities can increase or lower melting point. It will depending on the alloying element. A good example is bronze. It is an alloy of copper and tin with a melting point of 913 degrees Celsius.

· Crystal Structure

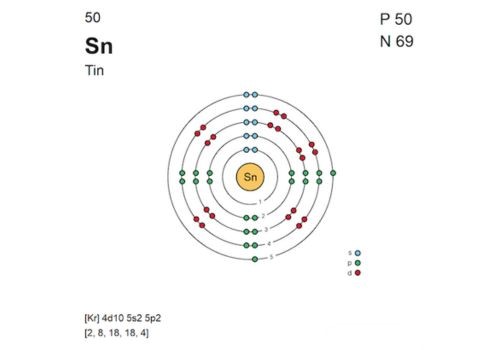

Tin has different crystal structures that have varying melting points. The structure is arranged in a crystalline manner that affects its melting point.

· Presence of an Oxide Layer

Oxidation often forms or creates a barrier that affects the melting point of tin. Actually, the oxide layer is a form of impurity that is likely to increase tin melting temperature.

Limitation of Tin Low Melting Point

· Temperature Sensitivity

You can only use tin in areas or conditions with low temperatures. This is because it can easily deform or melt on exposure to areas with high temperatures.

These characteristics limit where you can use tin.

· Mechanical Strength

Pure tin is soft, it does not have high mechanical strength. Therefore, you can’t use it in applications that require high strength and durability.

· Alloying Challenges

Tin is mostly alloyed with other metals to help improve or increase its properties. During this process oxidation or contamination might occur on the surface. As a result, this may interfere with the melting temperature.

Applications of Tin due to Low Melting Point

· Soldering

Tin solder wire plays an important role in electronics industry. You can use it to join parts and components.

· Plating or Coating

Tin is used in plating and coating. That is, electroplating surfaces help build a barrier or prevent corrosion and give items esthetic appeal.

With low melting point, the energy needed during tin electroplating is relatively low.

· Medical Application

The medical industry uses tin mostly in dental applications to help lower toxicity. Besides, tin fluoride help reduce bacteria formation.

· Casting and Molding

You don’t need high temperature to fabricate tin due to low melting temperature.

· Specialized Alloys

Due to its low melting point, it is mostly used as an alloy with other metals to make utensils and other components.

Conclusion

Clearly, tin is a metal with relatively low melting temperature. In its pure form, the melting point is low, however alloying elements such as copper may increase melting temperature.