Fabricating sheet metal brass can be a profitable business with the right information. A reason this guide will take you through fundamental aspects of fabricating sheet metal brass parts.

Types of Brass Sheet Metal in Fabrication

In sheet metal brass fabrication, you find different types and/or grades of brass applicable:

Fabricated Brass Parts

- Leaded Brass

Contains lead as an alloying element constituting about 3.5% which is helpful in increased strength for fabrication. Leaded brass finds use in making parts such as: fittings, architectural hardware, bearings and general purpose parts for machines.

- Cartridge Brass

Cartridge brass is an alloy combining copper and zinc in a 70:30 ratio with a beautiful yellow hue. Metal sheets of cartridge brass are highly workable with good ductility finding use in plating operations.

- Naval Brass

Contains copper, zinc, tin and lead finding use in marine applications such as making shafts for propellers and other hardware. Tin and lead contribute to less than one percent of the alloy structure but greatly improve brass’ mechanical properties.

More Resources:

Properties of Brass Useful in Sheet Metal Fabrication

Sheet metal brass has certain unique properties that allow for its fabrication by undertaking different operations such as forging and forming. Some of these properties include:

1. Antibacterial Properties

Sheet metal brass parts can prevent bacterial development and virus growth on its surface. This property is useful where hygiene is paramount such in making medical tools and hospital furniture.

2. Durability

Another distinguishing property of sheet metal brass is its excellent durability which enables it withstand wear and tear. Consequently, you can fabricate brass parts for use in highly stressful environments such as construction and as musical instruments.

3. Electrical and Thermal Conductivity

When fabricating parts for electrical applications, sheet metal brass is applicable owing to its good conductivity. Brass can also tolerate high temperatures allowing its use in thermal sensitive applications.

4. Finishing Capabilities

There are a wide range of surface finishes applicable on sheet metal brass including mill, long grain, satin and mirror finishes. This allows fabrication of decorative parts and implementation of aesthetic designs.

5. Improved Resistance

Sheet metal brass demonstrates increased resistance to corrosion, tarnishing, and chemicals thanks to its elemental constitution. Thus, you can fabricate parts from sheet metal brass for use in highly corrosive environments.

6. Malleability

Sheet metal brass offers great malleability which allows for fabrication operations such as cutting, punching, bending and drilling. Malleability of sheet brass metal makes machining possible without damaging results such as cracking.

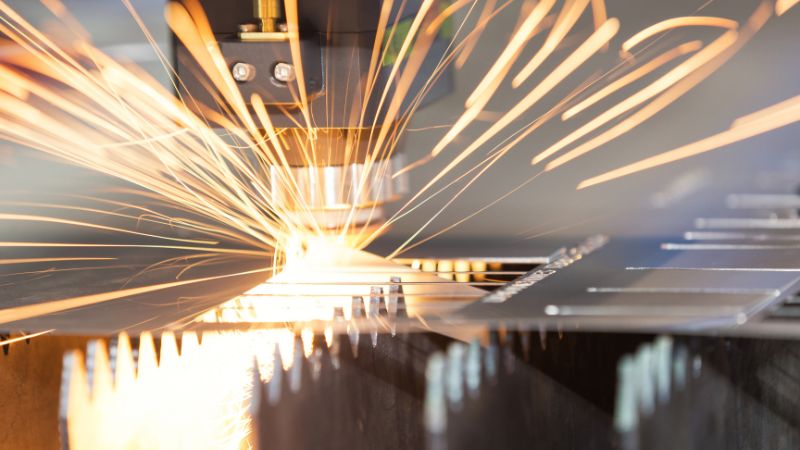

Laser Cut Brass Parts

Application of Sheet Metal Brass Fabricated Parts

Parts fashioned from sheet metal brass find use in various applications some of which you find below.

- Automotive parts: Brass sheets finds use in making automotive parts such as panels and numerous machine components like gears and bearings.

- Blank tags: Blanks tags fashioned from brass sheets find use in making identity tags, decorative applications, and ornamental purposes.

- Decorative parts: Conversion of brass sheets into decorative elements is due to its aesthetic superiority, corrosion and tarnish resistance.

- Keyboard plates: Thick brass sheets find use as keyboard plates offering better appearance, resistant qualities, strength and sound than other metals.

- Instruments: Fabricated brass sheets find use in making frames for musical instruments such as the horns, trombones and saxophones.

- Spinning bowls: Use of brass sheet metals in fabricating spinning bowls heavily relies on its electrical conductivity, corrosion resistance and durability.

Fabrication Processes Common in Sheet Brass Fabrication

Sheet metal brass fabrication is essential in presenting parts for product development. The following processes encompass such fabrication:

Sheet Metal Brass Cutting

The cutting fabrication process involves removing material from brass sheets to reduce size and/or achieve a certain shape. There are different techniques applicable in brass sheet cutting including punching, blanking, stamping and shearing.

Sheet Metal Brass Forming

Brass forming involves systematic distortion and bending of brass sheets into suitable parts. Press brakes with numeric control roll brass sheets with the resulting parts changing state but retaining their volume.

Sheet Metal Brass Welding

Brass sheet welding entails joining brass pieces to form complete parts according to designs. Some of the welding methods applied are TIG and MIG welding and even laser welding.

Sheet Metal Brass Fabrication Surface Treatments

Application of surface treatments on brass sheets during fabrication serves two major purposes:

- To enhance resistance to corrosion and abrasion

- To enhance the thickness of the coating

Some of the applied surface treatments include:

Sheet Metal Brass Galvanization

Brass galvanization involves dipping brass parts into molten zinc to form a protective coating with impeccable corrosion resistance.

Advantages

- Enhances resistance to corrosion.

- It is an economical method due to the low cost requirement.

- Results in an even and long lasting finish.

- It is a fast process.

Applications

- Electronic equipment such as electronic boxes

- Automotive components

- Machine parts and toolboxes

- Light fixtures such as chandeliers

Sheet Metal Brass Powder Coating

With this surface finish, you electrostatically apply a dry powder over the brass substrate to form a rigid coating upon curing.

Advantages

- Allows colour application and different textures

- Avoids dripping or paint run as with normal paint

- Has a short curing time

- Results in a thick and even surface finish

Application

- Vehicle Components

- Outdoor signage and furniture

- Doors and windows

- Home appliances

Sheet Metal Brass Anodizing

Employs passive electrolysis to thicken the surface layer of brass metal for enhance corrosion protection.

Advantages

- Increased surface hardness

- Achieves a smooth and uniform coating

- Dyeing enhances appearance through colour addition

- Enhanced resistance to corrosion, wear and abrasion.

Applications

- Construction materials such as roofs

- Industrial structures such as oil platforms

- Home appliances such as white goods

- Scientific instruments and computer hardware

Sheet Metal Brass E-Coating

Involves application of a thin layer of epoxy paint over the brass substrate by running an electric current through a solution. The solution is water-based and typically contains the desired coating pigments.

Advantages

- Ability to function as primer for other surface treatment

- Achieves a durable and uniform thickness

- Can increase the thickness of the surface.

- Improves resistance to corrosion

Application

- Hardware tools and equipment

- Marine and automotive parts

KDMFAB Capability in Brass Fabrication

At KDMFAB we handle all your sheet metal brass fabrication needs. From standard sheet metal fabrication processes to precision sheet metal fabrication needs.

With years of experience, we understand how difficult fabricating brass parts can be. A reason we offer complete solution for all your brass parts fabrication.

Whether you want:

- Precision laser cutting brass

- Welding brass

- Punching brass sheet metal

- Applying surface finish on fabricated brass parts or,

- Blanking brass sheet metal

KDM offer complete solution for all brass sheet metal fabrication processes.

Contact us now for all your brass fabrication.

More resources:

Custom Sheet Metal Fabrication – Source: KDMSteel

Sheet Metal Fabrication – Source: KDMFAB

Bronze Sheet Metal Fabrication – Source: Xomerty