Before starting any galvanized sheet metal fabrication process, read this guide.

It explores everything you are looking for about fabricating galvanized sheet metal. Whether you want to learn about the benefits, process, material choice or applications – all information you are looking for is right here.

Let’s dive right in:

What is Fabricating Galvanized Sheet Metal?

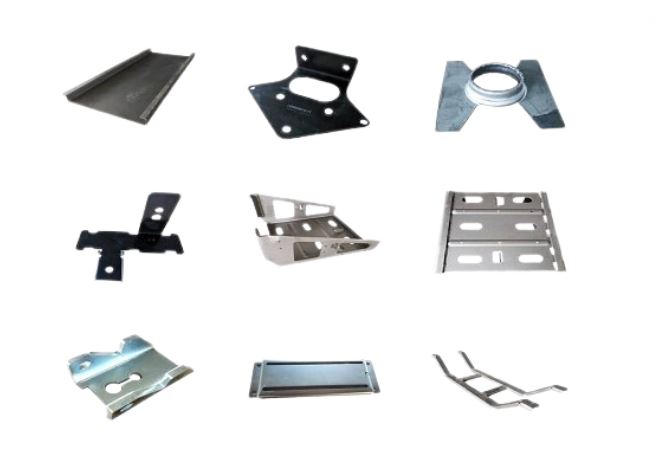

In this case, fabrication is the process where you change galvanized sheet metal into useful products. You will use a suitable technique – be it cutting, bending, welding, riveting, punching, or stamping to form useful structures.

Advantages Of Fabricating Galvanized Sheet Metal Parts

Galvanized sheet metal fabrication is becoming popular across many industries. It is due to the numerous benefits with regards to performance and durability.

Here are some reasons why you should consider fabricated galvanized sheet metal parts:

- Corrosion or rust resistant – the zinc coating forms a barrier between the sheet metal surface and external environment. As a result, preventing possible corrosion and rusting.

- Enhanced durability – as long as your fabricated sheet metal parts do not rust, they will serve you for many years.

- Fabricated sheet metal parts suitable for virtually all environmental conditions – galvanized sheet metal parts perform well even in harsh weather conditions. It is because they neither rust nor corrode. As a result, they are versatile and sustainable.

In short, galvanizing sheet metal mainly enhance the rust resistance properties. In fact, it has better performance properties than other protective procedures such as plastic coating or painting.

Actually, the idea is to protect fabricated galvanized sheet metal parts by:

- Zinc acting as protective layer for the base metal

- Zinc coating prevents corrosive environmental conditions or substances from the sheet iron or steel

- By acting as a sacrificial anode, zinc coating will always protect iron or steel.

Materials Suitable for Galvanized Sheet Metal Fabrication

One fundamental thing you must note here – this sheet metal fabrication process focuses on galvanized materials.

Therefore, it implies you can use:

Galvanized steel sheet – Ideally, these are the normal steel sheets having a special protective layer. The only difference in this case is the zinc coating which enhances corrosion resistance properties. Otherwise, all the other steel properties and benefits remain the same.

Galvanized iron sheet metal – These are iron metal sheets with zinc coating. The zinc coating protect sheet iron material from rusting and corrosion. So, the other properties of iron, still remain the same.

Even as you focus on these material, you must consider industry standards such as:

- Galvanized A653 (CS Type B)

- Galvannealed A653 (A653M-16)

In short, the techniques you will use in galvanized steel metal fabrication process is similar to galvanized iron sheet metal fabrication process.

Applications Of Fabricated Galvanized Sheet Metal Parts

Galvanization make iron or steel sheet metal corrosion resistant. As a result, it can withstand adverse weather conditions.

For this reason, you will find fabricated galvanized sheet metal parts in many industries such as:

- Construction industry to make ladders, HVAC systems, beams, frames, etc.

- Automotive industry – examples include vehicle parts such as fenders, hoods, etc.

- Electronics industry to make enclosures, instruments, etc.

- Road construction – making bridges,

Other industries may include power generation, oil and gas, food processing, and telecommunication, amongst others.

In short, galvanized fabricates sheet metal parts play an integral role in virtually all industries. As long as you need corrosion resistant and strong material.

Important Considerations in Galvanized Sheet Metal Fabrication

At times, the questions arises – whether you should galvanize sheet metal before or after fabrication process. Well, this may depend on many factors.

As a general rule, you should work with experienced galvanized sheet metal fabricators. They will advise you accordingly.

Here are some general rules when it comes to galvanized sheet metal fabrication:

Bending galvanized sheet metal – there are instance you may experience cracking when bending sheet metal after galvanization. There are two options here – you can repair the cracked sections, or use advanced sheet metal galvanization techniques.

Welding galvanized sheet metal – At times, achieving consistent and uniform weld may be a challenge. A reason you should monitor the entire welding process to ensure compatibility.

Depending on the sheet metal parts you are fabricating, you can galvanize after completing the welding process. However, at times this may not be possible.

Surface distorting – With proper design, you can easily eliminate possibility of surface distortion during sheet metal galvanization process.

For example, fabricating sheet metal parts with uniform thickness and symmetrical designs will significantly eliminate surface distortion or warping.

Prepare fabricated sheet metal surface before galvanization – You should clean and pre-treat the surface. This will ensure proper adhesion of zinc coating.

Assembling moving sheet metal parts – It is advisable to galvanize moving sheet metal parts separately.

Consider masking – In case you don’t want to galvanize the entire surface of fabricated sheet metal part, masking is always ideal.

In addition to these, you must ensure the parts conform to the stipulated industry standards. For instance, the parts should comply with the ISO 1461:2009.

It is the only way your component will guarantee a long service lifespan.

KDM Capability In Galvanized Sheet Metal Fabrication

For over 2 decades now, KDMFAB has devoted to sheet metal fabrication.

As a company, we offer a range of galvanized sheet metal fabrication solutions depending on client’s requirements and designs. Whether you want KDMFAB to:

- Cut galvanized sheet metal

- Bend galvanized sheet metal

- Weld galvanized sheet metal

- Punch, stamp or engrave galvanized sheet metal or

- Apply additional surface finish

KDMFAB has the expertise and capability to handle all your project’s needs.

Even when it comes to precision sheet metal fabrication, KDMFAQ uses CNC machines including laser cutters, precision welding machines, milling machines, and many more.

We inspect at fabricated galvanized parts to ensure the meet the recommended quality standards and specifications.

Contact KDMFAB now for all your galvanized sheet metal fabrication needs.

FAQs

What Is Sheet Metal Galvanization?

Galvanization is the process where you apply anti-rust or anti-corrosion coating on iron or steel sheet. In most cases, you will use zinc coating which forms the protective layer.

How do You Galvanize Sheet Metal for Fabrication?

There are many techniques you will use to galvanize sheet metal for fabrication. You can consider any of these options:

Hot-dip galvanizing sheet metals – it is a popular technique where you submerge sheet memnmnmnmnmtal in molten zinc. In fact, the technique has been around for more than 10 decades.

In fact, it is the most economical, reliable, and durable way to galvanize steel or iron.

Electrogalvanizing – Unlike hot dip galvanization; here you will use electroplating. You will use electroplating technique to bond zinc layer on sheet metal surface.

With electrogalvanizing, you can achieve very lower thickness and high accuracy. Additionally, you will get better surface finish.

Sherardizing/Dry galvanization – You will heat fabricated sheet metal parts in a rotating drum with metallic zinc. The zinc dust will evaporate and diffuse in sheet metal.

It is a perfect for fabricated sheet metal parts requiring coating on the inner section.

Thermal spraying – Here, you will spray sheet metal surface with appropriate coating material. Once the coating particles reach the sheet metal, they flatten and adhere on the surface.

Of course, the process requires heating.

Conclusion

Fabricating galvanized sheet metal parts offer unmatched parts performance and durability. Reason being, fabricated galvanized sheet metal parts are corrosion resistant.

At KDMFAB, we will help you get the best parts for your unique applications – contact us now.

More Resources:

Sheet Metal Fabrication – Source: KDMFAB

Sheet Metal Finishing – Source: KDMFAB

Galvanization – Source: Wikipedia

Galvanized Iron And Steel – Source: GSA