Picture Frame Fabrication

KDM has a large selection of picture frames constructed of high-quality sheet metal. With superb advantage, standard or bespoke frame outlines are available including durability, beautiful designs, lightweight, and corrosion resistance.

Aside from that, all unique configurations are available like: steel painting frames, welded frames, hanging picture frames, art picture frames, etc. All are fully configurable, with a variety of surface coatings and features.

Metal Frame By Features

Picture Frames by Materials (4)

Frames By Color (4)

Fabrication Capabilities

KDM can manufacture bespoke sheet metal picture frames based on your preferred application. For almost a decade, KDM has been creating picture frames out of various sheet metals.

We have our own factory in China, where we can create unique designs and provide custom services to meet your requirements. KDM can also print your personalized logo to help promote your business.

Why Choose KDM Sheet Metal Picture Frame

Sheet metal picture frames come in a variety of sophisticated designs to complement any photography or art collection. Because of their visual appeal, these are ideal for any recollection. Different finishes and styles to choose from, all of which are perfect for complementing drawings, decorations, portraits, designs, or creativity.

KDM is the ideal option if you own a company and need to acquire sheet metal picture frames from China. We are ready to support what you need.

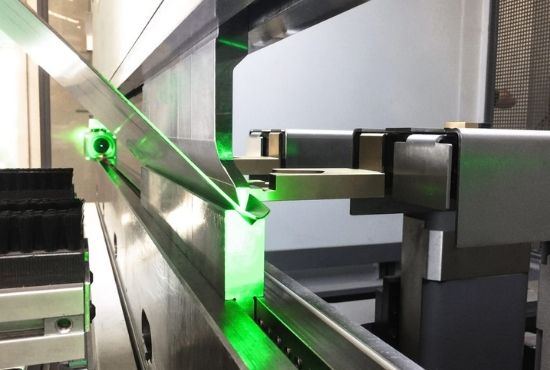

KDM Sheet Metal Picture Frame Manufacturing Line

- Gallery

- Details

KDM can work closely with your company’s needs in order to give you the high-quality services you deserve. That is what distinguishes us as a valuable and trustworthy partner to our clients.

- Support customization of color, design, sizes, and materials.

- OEM are ODM welcome.

- After-sale protection service.

- Small order is available.

- Superior favorable price good service.

- Best quality products.

- Customization based on client’s specifications.

- Strong production capacity.

- Skilled workers to ensure good quality.

- Very prompt and professional communication to all your queries.

Please contact us if you have any questions about sheet metal photo frames. We provide online support 24/7 to meet your needs.