Before fabricating titanium sheet metal, read this guide.

It will guide you on properties and various fabrication processes. Besides, you will also know the various applications of fabricated titanium parts.

Let’s dive right in.

Titanium Properties to Consider in Sheet Metal Fabrication

When employing titanium in sheet metal fabrication, consider the following properties:

i. Composition

Titanium occurs naturally and you can find it in its pure state or as an alloy. Working with titanium in its pure form is challenging while its combination with aluminum and vanadium makes the most common alloy.

ii. Durability

Titanium offers exceptional resistance to corrosion and can sustain extremely high temperatures. Therefore, titanium is essential in fabrication of parts intended for use in hostile environments with chemicals and moisture presence.

iii. Elasticity

Titanium’s elastic performance pales in comparison to steel making it challenging to machine and produce unique pieces. Consequently, this greatly increases the processing titanium sheet metal fabrication cost.

iv. Hardness

Steel offers better hardness feature than titanium and thus a better option where hardness is necessary. Titanium alloys can offer you better hardness performance but still lower than steel.

v. Weight

Use of titanium is down to its low density and excellent strength-to-weight ratio. Consequently, where your application requires fabrication of strong but light material, titanium is an excellent option.

vi. Yield Strength

Despite its superior strength per unit, titanium’s tensile yield strength is inferior to steel. Titanium’s use is desirable where both strength and weight are important considerations such as in aircraft designs.

Titanium Alloys Applicable in Sheet Metal Fabrication

Some of the industry wide alloys and grades of titanium employed in sheet metal fabrication are:

A. Alpha Alloys: These comprise alpha stabilizers like oxygen and aluminum and/or alloying elements that are neutral like tin. These titanium alloys are not subject to heat treatment and therefore only cold worked during fabrication.

B. Near-Alpha Alloys: Have a minimal presence of ductile beta-phase with about two percent stabilizers like vanadium, silicon or molybdenum. These alloys respond well to drawing during fabrication.

C. Alpha and Beta Alloys: Contain a combination of stabilizers of alpha and beta persuasion, are metastable and respond to heat treatment.

D. Beta and Near-Beta Alloys: Have enough beta stabilizers like silicon, vanadium and molybdenum while exhibiting meta-stability. The beta stabilizers help retain the beta phase while allowing strength improvement through aging and solution treating.

Fabrication Processes in Sheet Metal Fabrication of Titanium

Sheet metal fabrication of titanium involves the following fabrication processes:

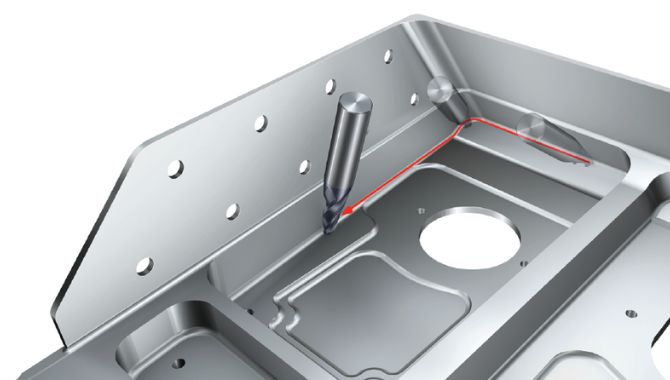

Machining

When machining titanium, consider galling, which is its tendency to smudge other metals and its comparatively poor thermal conductivity. Employ a sturdy machine with a refined cutting edge using slow, dense cuts with lubrication for swarf removal.

- Planing: Considering the machine’s required stiffness, speed, and feed you can easily shape and plane titanium. Employing large radius tungsten carbide tools produces a thin and broad chip.

- Drilling: Employ intermittent high-speed steel drills when drilling titanium making the holes as shallow as feasible. Retracting the drill periodically to remove the swarf and employing flood lubrication for friction reduction is essential when making deeper holes.

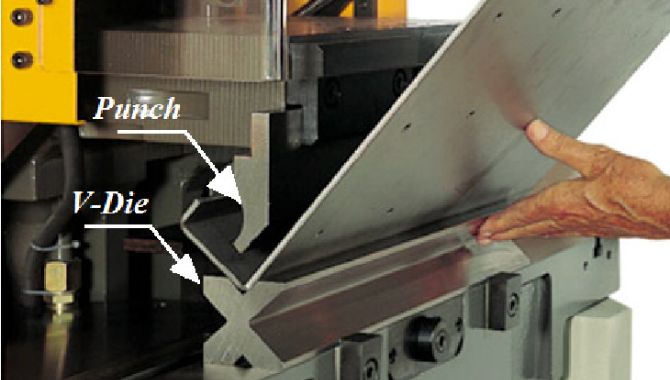

Bending

Power brakes form angle and channel sections employing a punch and channel die. The punch stroke depth determines the bend and spring-back allowance with molybdenum disulfide as lubricant.

Hot Working

The temperatures when hot working titanium are a little lower than that employed for steels. At high temperatures, maintain titanium for a brief period before forging to reduce surface contamination which increases rapidly with temperature.

Forging

Titanium shares similar press and hammer forging methods with low-alloy steels. Reduced reheating requirements and a well-designed fabrication plant reduces contamination during the process.

When drop forging, employ die contours with fillets and wider radii than steel’s due to titanium’s lesser thermal expansion. Carry out trimming in a hot environment and successively from hammering to reduce preheating.

Heat Treatment

Using a standard furnace to heat titanium will result in surface contamination and probably absorption of hydrogen. An electric furnace is preferable as it features reduced hydrogen absorption.

Fuel-fired furnaces are inappropriate as the titanium quickly picks-up any hydrogen presence from the environment, which is damaging to thin parts. Higher annealing and preheating temperatures, invariably causes superficial hardening via oxygen diffusion necessitating surface with heat treatment.

Forming

Some of the most common forming techniques you can consider include:

i. Drop Hammer Forming

When undertaking drop hammer forming with titanium, you require heat application by employing heated blanks. Deformation has to be by stretching or bending due to titanium’s poor shrinking properties.

Titanium may require additional stage dies than other materials due to its low ductility. Friction sawing trims the parts formed by drop hammering with hard rubber pads utilized for additional pressure to address deformations.

ii. Hydro-Press Forming

Forming titanium in a hydro-press is challenging due to spring-back, high yield strength, and shrinkage restriction. Using heated blanks reduces these issues, with application of high pressure on the titanium allowing fully formed pieces.

iii. Stretch Forming

Stretch forming typically succeeds brake forming and annealing when fabricating titanium resulting in channel sections and curves. Variations in yield strength create uncontrollable spring-back, whereas gage fluctuation may result in local necking.

You can also create curved parts in titanium by combining a hot form finish with stress relief through cold or warm stretching.

Deep Drawing

Deep-drawing titanium pieces requires a hydro-form press with high forming forces instead of a traditional mechanical press. When undertaken in stages with interim anneals, this approach can produce very deep drawings.

Welding

Some of the welding techniques you can employ with titanium are TIG, MIG, resistance spot and seam, electron beam and plasma welding. Phase shifts and contamination are the essential properties of titanium (and alloys) during welding.

Pure titanium and alpha-phase alloys produce strong and relatively ductile welds but with low tension-shear strength ratio. Beta alloys produce spot welds that are brittle due to transformation hardening.

Fusion welding titanium requires precautionary measures to prevent molten weld contamination. Employing a controlled environment and inert gas (helium or argon) shielded arc techniques can result in sound welds.

Surface Treatment and Descaling

Heating titanium or its alloys in an open furnace causes oxide and/or nitride formation which requires removal to maintain mechanical properties. Surface treatment using caustic soda at high temperature for a defined period can induce descaling.

Advantages of Using Fabricated Titanium Parts

Employing titanium in sheet metal fabrication has the following benefits:

i. Corrosion Protection

Titanium reacts with atmospheric oxygen to form a thin oxide layer that is impenetrable shielding the underlying metal from corrosive agents. Consequently, you can fabricate titanium sheets for exposed outdoor applications.

ii. High Melting Point

Titanium has an elevated melting point making it ideal for fabrication of parts employed in high temperature applications. Additionally, this property allows titanium to resist temperature changes thus maintaining its structural integrity.

iii. High Strength-to-Weight Ratio

Titanium offers you immense strength despite its small weight making it ideal where weight and strength are an issue. While its strength is comparable to steel’s it is a lighter option finding use in areas such as aviation.

iv. Non-Toxic and Biocompatible

Titanium is not hazardous due to its chemical inertness thus posing no harm to living organisms and the environment. Fabricating parts for use in the medical world such as body implants and braces is therefore possible with titanium.

v. Recyclable

The inertness of titanium allows it to withstand weathering over time making its lifetime cost lower than most metals. Additionally, you can recycle titanium and fabricate other useful parts mitigating its usually high production costs.

Limitations of Using Titanium in Sheet Metal Fabrication

Some of the limitations in sheet metal fabrication of titanium include:

a. High Cost

Titanium is an expensive metal thanks to its complicated production process. Difficulties in fabricating titanium makes its use limited despite its superior properties.

b. Casting and Fabricating Difficulties

Casting titanium is a process encumbered with great difficulty given its unique characteristics like strength and high melting point. Fabricating titanium sheets features numerous closely controlled procedures to ensure quality parts.

c. Deformation

Titanium has a low elastic modulus which makes it susceptible to deformation upon application of rigorous fabrication methods. Consequently, titanium requires keen fabrication to prevent defects such as warping and undesired bending.

d. Galvanic Coupling

Titanium creates a galvanic couple when it directly contacts a different metal under an electrolyte, hastening corrosion of either or both metals. Galvanic coupling hinders fabrication of titanium sheets employing other elements since it usually is the catalyst.

Application of Titanium Sheet Metal Fabrication Parts

Parts transformed from fabricating titanium sheets find use in the following industries:

i. Aerospace

Titanium’s capacity to withstand corrosion and heat alongside its impeccable strength-to-weight ratio allows its use in aviation applications. Titanium parts help build aircraft parts such as airframes and jet engines.

ii. Power Generation

Use of titanium parts in power generation is exemplified in instances such as fabrication of firewalls and protective assemblies.

iii. Automotive

Automotive application of titanium is limited to high performance vehicles due to the high fabrication costs. Engine parts like springs and wrist pins employ fabricated titanium.

iv. Petroleum Industry

The corrosion resistance of titanium allows its use in off-shore petroleum extraction platforms and equipment such as production risers.

v. Biomedical

Titanium and its alloys find extensive use in the medical world in creating implants such as bone plates and joint replacements.

Conclusion

As you can see, fabricating titanium metal is practical and slightly challenging. We hope the information in this guide will help you for successful titanium sheet metal fabrication. Request a titanium sheet metal fabrication process PDF for more information.

More Resources:

Titanium – Source: Wikipedia

Titanium Alloy – Source: Wikipedia

Sheet Metal Bending Parts – Source: KDMFAB

Fabrication of Titanium – Source: Total Materia