Aluminum is one of the most preferred choices for sheet metal fabrication because of its characteristics. They are flexible in nature, cost-effective, and have a wide selection of options and grades.

KDM aluminum sheet metal fabrication is ideal for aerospace and marine application due to its high-strength and corrosion-resistant properties. Besides, they are highly machinable, weldable, and weather-resistant.

KDM is a leading aluminum sheet metal fabrication in China. We work with various aluminum alloy grades to match your preferences. KDM provides various fabrication services such as forming, cutting, bending, rolling, and stamping.

If you need custom aluminum sheet metal fabrication services, please don’t hesitate to contact us today!

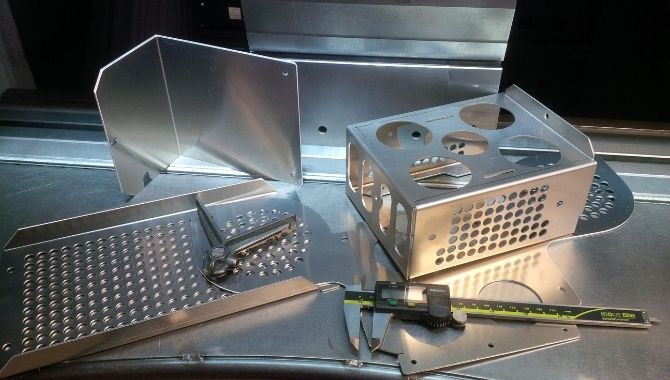

KDM offers aluminum sheet metal fabrication to form different equipment for various industries, such as medical, automobile, telecom, construction, etc.

KDM has a wide range of aluminum stamping parts with close tolerance of 0.01-0.05mm. It is available in various surface treatments like powder-coated, painted, polished, etc.

KDM produces anodized aluminum parts for various applications such as enclosures, computer cases, cabinets, boxes, and so much more. It can guarantee lightweight and durability.

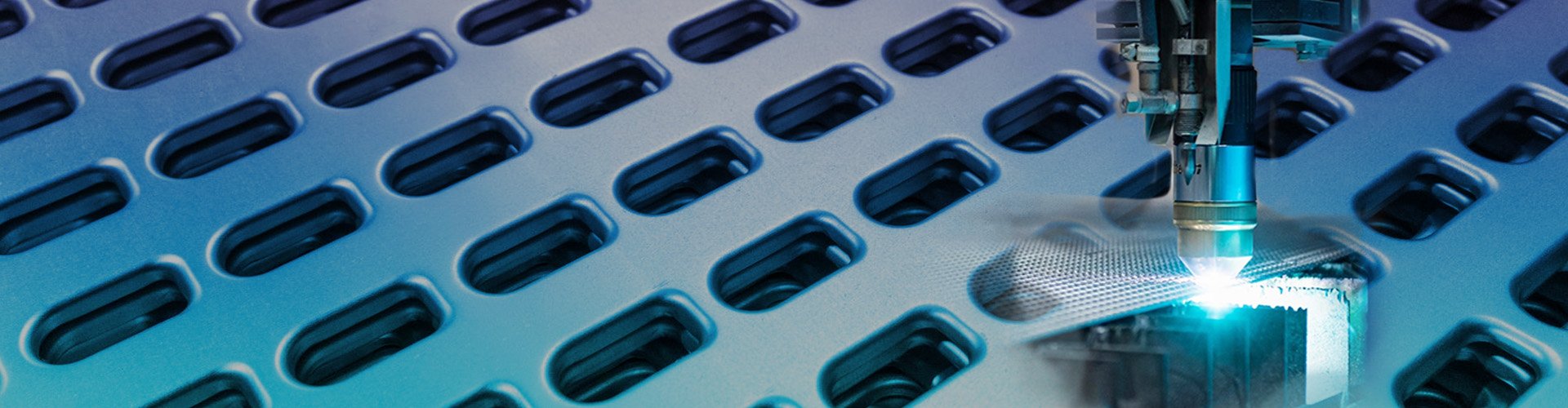

We specialized in aluminum laser cutting fabrication with numerous surface treatment services. Among them are anodizing, chrome plating, painting, and more.

KDM provides custom aluminum sheet metal fabrication that meets the requirements of every industry. We can custom aluminum parts and components according to your specifications.

KDM offers aluminum bending parts for aerospace, medical, telecom, marine, and many more industries. It can be available in various surface treatments like powder-coated, anodized, or customize. Send us your specifications.

Aluminum sheet metal fabrication is a cost-effective alternative to plastic fabrication. They are more heat resistant and improved strength.

Aluminum sheet metal fabrication can be used in many ways. It can perform welding, laser cutting, forming, machining, and bending.

Aluminum is well known for its lightweight characteristics. They are cost-effective solutions for any fabrication project that requires versatility.

KDM aluminum sheet metal fabrication provides excellent surface finish such as painting and chrome plating. It can also be anodized into numerous colors.

High-End Manufacturing Tools

KDM uses high-end fabrication tools for aluminum sheet metal fabrication. We utilized bends, drill holes, and press brakes. These capabilities allow for the production of precise structures for industrial, residential, and commercial applications.

There are various processes for aluminum sheet metal fabrication. It includes forming, cutting, and welding. These processes entail the shaping of custom aluminum sheets into different sizes and shapes.

Aluminum Metal Grade

Aluminum has a wide range of alloy grade options, ideal for sheet metal fabrication:

- 1100-H14: It offers good ductility for deep draws and welding.

- 3003-H14: Provides corrosion resistant, weldable, low cost, and formable.

- 5052-H32: Suitable for applications like chassis or tanks.

- 6061-T6: Less weldable and formable compared to other grades. Suitable for aircraft applications.

Why KDM Aluminum Sheet Metal Fabrication

KDM uses premium-grade aluminum to fabricate numerous OEM products for different applications. We manufacture limitless aluminum parts, such as medical carts, kiosks, consumer products, medical equipment, and so much more.

At KDM, we have over a decade of aluminum fabrication experience. We have rich experience in fabricating and designing precision metal parts with aluminum materials. From designing, and fabricating to delivering your custom aluminum part, KDM can assist the whole project.

Send us your inquiry now!

Custom Aluminum Sheet Metal Fabrication

The aluminum components include enclosures, housings, brackets, cabinets, panels, chassis, and framing. They are widely used in almost all industries, such as:

- Custom Projects

- Medical

- Avionics/Aerospace

- Defense/Military

- Energy

- Gallery

Related Product

- Sensibly organize the hardness inspection procedure of heat metal fabrication parts.

- Stringently regulate every sheet metal parts that need intermediate annealing before annealing to avoid severe damage.

- Proper intermediate heat treatment and final heat treatment variable should be detailed and the material properties should be strictly followed.

- Using thermoforming technology to process sheet metal parts with heating temperature and heat time strictly controlled.