Metal brackets are supportive structures that link, provide support, and reinforce two or more structures. They can act as either intermediate or final structures.

This guide explores all the fundamental facts about the custom metal bracket fabrication process.

From custom metal design, choosing metal, and fabrication to applying necessary finishing – you will find all information right here.

Step 1: Design Custom Metal Bracket

Custom metal brackets are designed according to specific customer requirements.

Choosing the best design is a critical step in the custom metal bracket fabrication process. You need a good design that can serve the intended purpose.

It does not matter whether you wish to use metal fabricated brackets as a supportive, final, or intermediate structure. It must conform to the necessary safety standards.

In fact, during the design process, you must understand the weight-bearing requirements, ease of installation, and use.

Even as you design your custom metal brackets, consider these shapes:

Custom L – Metal Brackets

L – Brackets are the most common profiles. As the name suggests, the profile conforms to the letter “L”.

These custom sheet metal brackets are suitable for mounting vertical or horizontal structures. The mounting sections or holes are on the L-shaped sections.

Custom Z Shaped Metal Brackets

Fabricating Z-brackets requires two bends on the same face of sheet metal. That is, the first bend will be in the inward direction while the second bend on the outward direction.

It is a perfect choice for mounting offset or parallel items.

Custom U Metal Brackets

They have a letter U-shaped profile with protruding sections on the opposite sides. In most cases, the protruding sections have holes or mounting sections.

Custom Gusset Metal Bracket

Gusset brackets are popular for their:

- High load-bearing capacity

- High strength

Although the main structure in the gusset bracket resembles the L-metal bracket, it has additional reinforcements on the two opposite sides. Normally, the reinforcements come as two triangles welded on the two sides.

Custom Offset Metal Brackets

The mounting style in offset brackets tends to resemble the Z-bracket. However, these brackets are suitable for mounting parallel surfaces.

Again, you can use these metal brackets just like the U designs.

Custom Metal T Bracket

These brackets come in a letter “T” shape for different applications. The installation holes are on the surface of the T bracket.

The T metal brackets are multi-purpose. They make it easier to expand the structural designs.

Custom Flat Metal Bracket

They come as flat and straight metal bars. Depending on the designs, they may have installation holes or hooks

Custom Metal Tri-corner Bracket

These are unique metal brackets with an L-shaped profile. However, one section has a solid rectangular structure attached to the base section.

Apart from the options mentioned above, you can also have unique designs according to specific application requirements.

The design will depend on whether you want to support countertops, window sections, or any other structural component. You can choose:

- Floating shelf metal bracket

- Foldable corner metal bracket

- Brackets for stone cladding

Apart from knowing the custom metal bracket design, it is important to specify the applications.

Know Where You Will Use the Metal Bracket

You may intend to use custom metal brackets in many applications including:

- Supporting countertops

- Mounting items such as televisions

- Joining structure,

- Decorative applications, etc.

Many industries use custom metal brackets including construction, defense, architecture, aerospace, electrical and electronics, etc.

Knowing specific applications will help you choose proper reinforcement for optimal performance. Of course, this is as far as the weight-bearing capability is concerned.

Step 2: Choose the Right Material for Custom Metal Brackets

There are many engineering materials you can use for custom metal bracket fabrication. The material type also makes an import classification criteria.

Here are some common options to choose from:

Custom Brass Brackets

Brass brackets are corrosion-resistant, easy to cast, and can handle the high temperature. Additionally, you can achieve a good finish, and they are resistant to tarnishing.

Custom Copper Brackets

Copper brackets are known for being excellent heat and electricity conductors. They have a bright finish, durable, safe, and easy to cut.

Custom Stainless-Steel Brackets

Stainless steel brackets have excellent corrosion resistance properties. These metal brackets are durable, strong, and easy to fabricate.

Additionally, they have an excellent surface finish.

Apart from stainless steel, you can choose galvanized steel brackets.

Custom Aluminum Brackets

Custom aluminum brackets are lightweight, corrosion-resistant, and recyclable. These metal brackets are highly durable.

Remember, depending on your requirements, you can use virtually any material to fabricate custom metal brackets.

Now, once you have the design and material, it is time to make the custom metal bracket fabrication.

Step 3: Fabricate Custom Metal Bracket

Although there are many ways to make metal brackets, fabrication remains a cost-effective and reliable option. Whether you are targeting small or large-scale production, fabricating metal brackets is still a viable option.

Casting Custom Metal Brackets

For specialized designs, with intricate features, casting metal brackets can be a viable option. The process involves:

- Mold making – you will use stainless steel or aluminum to make the mold. The mold resembles the metal bracket shape and design.

- Melting Material – choose material for the metal bracket. Melt the material then pour it into the mold.

- Cooling and ejection – allow the molten material in the mold to cool. Then, ejected the casted metal bracket and apply the necessary surface finish.

Ideally, the casting technique is suitable for making gusset brackets. It will ensure the entire gusset bracket structure has uniform strength without any point of weakness.

Fabricating Custom Metal

Fabricating sheet metal brackets is a fast, cost-effective, and straightforward process. Although the sequence during the fabrication process may vary, it involves:

Cutting Sheet Metal

You will cut a section depending on the metal bracket dimensions. There are many techniques you will use to cut sheet metal:

Bending Sheet Metal

Custom metal brackets may have one or more bends.

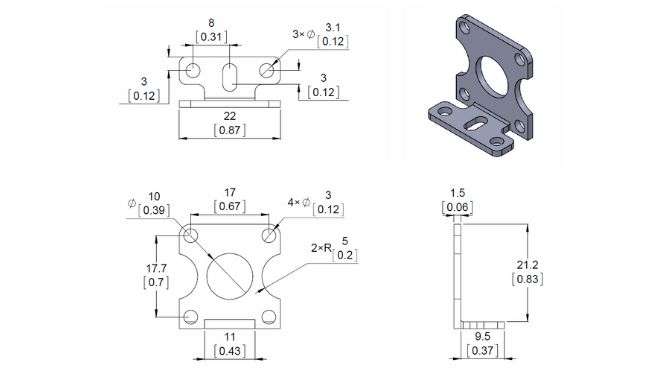

At this point, you will bend the sheet metal depending on the specifications on the drawing. These may include the bending length, bending angle, bending radius, etc.

The bending axis will depend on the sheet metal bracket design. For instance,

U – bracket requires bending along two axes

L – bracket requires bending along a single axis

Depending on the bending degree, you can use folding, V-bending, bottoming, coining, wire bending, or roll bending techniques.

More resources:

Factors to Consider When Bending Sheet Metal Parts

Drilling Holes on Fabricated Metal Brackets

You will create holes on strategic points on the metal bracket surface. The holes are such that they provide convenient installation.

Additionally, they determine the weight-bearing capacity and support for the metal bracket.

The number of holes will depend on the metal bracket size and intended application requirements.

You can drill or punch holes in the custom sheet metal brackets. Moreover, you may include fasteners on the brackets such as screws or rivets

Assemble Metal Brackets Parts

Assembly is critical in custom metal bracket fabrication, especially for complex designs. Depending on the metal brackets design, you can choose:

- Welding metal brackets

- Riveting metal brackets

- Join using bolts and nuts

You should ensure the joins are strong enough to provide support.

More Resources:

Rivets for Sheet Metal Assembly

Apply Surface Finishing

Although you may decide to leave the custom metal brackets as fabricated. Adding a surface finish will improve aesthetics or increase durability.

The finishing can also improve the metal bracket’s corrosion resistance properties. You can decide to:

- Anodize

- Powder coat

- Paint, Electroplate, or

- Subject parts the brackets to heat treatment

Lastly, where possible, you can label the custom brackets and design. In case you wish to export the custom structural brackets, then proper packaging is vital.

More Resources:

Bracket – Source: Wikipedia

What is the HS code for brackets?

How do you attach metal brackets to wood?

Conclusion

Custom metal bracket fabrication requires you to choose a design, material, and cost-effective manufacturing technique.

At KDM, we design and fabricate metal brackets depending on your unique requirements and specifications. You can contact us today for all your custom bracket needs.