Everyone wants a safe, durable, high quality and secure battery enclosure.

However, finding the right information about these battery boxes or cabinet is always a challenge. A reason this guide compiles everything about battery storage enclosures.

Whether you want to learn about design, manufacturing processes, functions, benefits, or applications – this guide is your go-to resource.

What is Battery Enclosure?

A battery enclosure is a housing, cabinet, or box. It is specifically designed to store or isolate the battery and all its accessories from the external environment.

The enclosures come in different designs and configurations.

Enclosure for Battery

Functions of Battery Enclosure Box

Battery box plays an integral role in both domestic and industrial applications. A reason you must invest in the best enclosure.

The main functions of battery box enclosure are to:

- Offer safe and reliable storage solution

- Protect the battery by isolating it from the external environment

- Make installing batteries in vehicles and other electronics simpler, easier, and more convenient

- Prevent unauthorized people from accessing the battery

- Ensure the EV battery is safe from thermal runaway

Additionally, it may also offer a safe and convenient way to carry or transport batteries.

Types of Battery Enclosure

There are many enclosure designs available in the market. However, for this section, the focus is on the main categories such as:

1. Outdoor Vs. Indoor Enclosures

Even though these two enclosures share many features and properties. The difference comes in the degree of protection.

Indoor battery cabinet should have at least NEMA 1 rating. On the other hand, outdoor enclosures for batteries should have a NEMA 3R rating.

It is important to note that the NEMA and IP rating varies depending on where you will install the enclosure.

Indoor Battery Box Enclosure

2. Mounting Mechanism for Battery Cabinet

It refers to how you will install the battery box. Among the many options you can consider are:

- Rack mount battery box enclosure

- Ground or Floor mount battery box

- Pole mount battery storage enclosure

- Wall mount enclosure

Pole Mount Solar Battery Box

3. Level of Protection

The degree of protection plays an important role in the classification criteria. It determines where you will use the battery storage cabinet.

For example, you may have NEMA 1 or a NEMA 3R battery box. Additionally, this also applies to the IP rating.

In the end, the required protection level will also determine the overall construction and design. Again, this is also instrumental when it comes to classifying battery boxes.

Take for example, an EV battery enclosure is slightly different from a solar battery enclosure.

4. Material for the Enclosure

In most cases, you will find aluminum and stainless steel battery cabinets.

Of course, we have galvanized steel, plastic, and composite materials.

A good material for the battery box should be:

- Easy to clean

- Durable and long-lasting

- Offer excellent thermal properties

- Resistant to corrosion and weather

So far, aluminum and stainless steel guarantee better performance.

Apart from these 4, you may classify battery box enclosures depending on:

- Surface finish – there are painted, powder coated, etc.

- Side – there are small, medium to large sizes

- Additional accessories – enclosures with ventilation systems, handles, alarms, etc.

To sum up, even as you focus on battery box enclosure types, it is important to evaluate the various features.

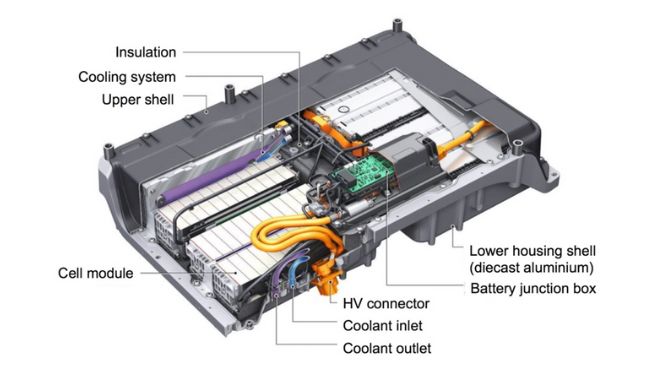

Battery Cabinet Parts and Components

There are many parts and components making these battery storage cabinets. These parts vary depending on the design, features, and functionality.

Let’s look at the most common parts:

Frame – it forms the outer structure. In most cases, you will mount or weld various panels on the structure. The battery storage cabinet may have top, bottom, and side panels.

Door – allows you to access the battery box enclosure. You can use hinges to attach the door to the enclosure structure. Again, the door should have a safe locking mechanism or latch.

In more advanced battery cabinets, they may have alarm systems.

Ventilation systems – they may integrate louvers. Depending on the enclosure design, the ventilation systems can be at the top or bottom section.

Ventilation systems also help during the cooling process.

Mounting mechanism – they vary depending on whether the battery storage cabinet is a pole mount, wall mount, or floor mount. The mechanism allows you to install the battery box enclosure appropriately.

Racks – these systems support batteries in the enclosure. Ideally, the battery rack should be strong.

Where possible, the rack should have electrical insulation near the battery terminals. Additionally, just below the racks, there is a need for trays. Any spillage from batteries will remain in the tray.

Mounting rails – you will install battery accessories and equipment in the rail. Many enclosures have DIN rail.

Electronic components –modern battery cabinet enclosures have sensors for smoke, shock, humidity, temperature, and moisture. These are safety measures to ensure the environment within the battery cabinet is safe.

However, such enclosures are costlier.

Air conditioner system – they help maintain a conducive environment within the battery box enclosure. Other accessories may include a heat exchanger system or fans.

Handles – provides an easy way to handle the battery cabinet.

Battery holding brackets – they ensure the battery is always in a fixed position (no movement).

Cooling plates – some have cooling plates that help to control the enclosure temperature.

Insulation system – insulation is also a safety measure a battery cabinet should have.

Grille – it allows for free air flow thereby ensuring efficient cooling.

Dual-stage venting system – It is a common technology in electric vehicle battery systems. The first stage will prevent water ingress and equalize pressure.

Stage two will ensure efficient airflow. It occurs during heat and pressure build-up. Still, you can use a single ventilation assembly to achieve this.

Generally, these are some of the main battery cabinet parts. Always refer to the product manual to learn more about the battery cabinet parts for a specific product.

Battery Box Enclosure Parts

Battery Cabinet Box Parts

Safety Features in Battery Box

Battery is a sensitive accessory. Therefore, any enclosure or cabinet housing battery must have certain safety measures.

Among the key safety requirements your battery box enclosure must comply with include:

1. Passing Quality Procedures

First, the material must pass all the necessary quality tests. Choose high-quality material grade.

Again, the material must pass the thermal test, and chemical resistance test.

2. Waterproof Battery Box

A good battery box enclosure should withstand extreme weather conditions such as wind, snow, extreme heat, or rain.

That’s where the IP rating and NEMA ratings come in. Depending on where you intend to use the battery enclosure, complying with the necessary ratings will guarantee safety.

3. Locking Mechanism

It will ensure that only authorized personnel have access to the battery compartment. Additionally, integrating an alarm system is an extra safety measure.

A self-locking mechanism would be a better option.

4. Electrical Grounding

Grounding will protect the battery and its accessories alongside users from electric shock.

5. Certification and Compliance

All enclosures for batteries should comply with certain safety regulations and standards. Therefore, you should check if the battery box enclosure is UL listed, CE, RoHS, and ETL listed.

As a general rule, the enclosure should ensure safety, while allowing a battery to function optimally.

Battery Enclosure Material

When it comes to choosing battery box enclosure material, you should consider:

- Durability

- Ease of fabrication

- Resistance to acids and alkaline solutions

- Unlimited surface finishing

- Thermal conductivity

- Weight, just to mention a few.

Currently, popular materials for battery box enclosure are:

Aluminum Battery Enclosure

Aluminum is a popular material for battery cabinets due to its superior properties. Ideally, aluminum is known for:

- Excellent corrosion resistance

- Sustainability since it is easily recyclable

- Better thermal properties

- Lightweight

- Durability and strength

- Resistance to impact

- Unlimited surface finishing

Steel Battery Enclosures

Stainless steel battery boxes and galvanized steel battery boxes are also common.

Of course, this is due to their:

- Strength and durability

- Better thermal properties

- Stainless steel has excellent corrosion resistance

- Temperature resistance

- Sustainability

- Low maintenance

Clearly, both aluminum and steel offer superior properties in battery cabinet construction.

Alternatively, you can also choose battery boxes made from plastic.

Actually, many electric vehicle battery box enclosures use thermoplastic polycarbonates. Polycarbonate is resistant to most alkaline solutions and offers superior mechanical properties.

Let’s compare metal enclosures vs. plastic enclosures for batteries:

| Plastic Enclosure for Battery | Metal Enclosure for Battery |

| Electrically insulated | May require insulation |

| Lightweight | Aluminum is lightweight but not like most plastics |

| When used outdoors for a long time, they deteriorate | Durable and suitable for indoor and outdoor use |

| They are durable and strong, but not as metal | Perfect choice where you require absolute strength and durability |

Additionally, composite materials are becoming a better alternative for constructing battery box enclosures. They are common in the EV industry.

How to Fabricate Battery Enclosure

There are many ways you can fabricate a battery cabinet. However, for this section, we will focus on the two most common options:

1. Fabricating Battery Box Enclosure from Sheet Metal

The process involves shaping sheet metal into a battery box enclosure. You can use this method to fabricate any enclosure size or design.

Let’s quickly look at the process:

- Step 1: Use CAD software to design the enclosure. You must specify all features at this stage.

- Step 2: Choose suitable sheet metal for the battery box. You can choose steel or aluminum material. They form the perfect option for battery cabinet fabrication.

- Step 3: With the dimension from step 1, cut the sheet metal to appropriate sizes. You can use a laser cutter, plasma cutter, Waterjet cutter, or any available option.

- Step 4: Form sheet metal where necessary. That is, you will bend sheet metal according to the battery cabinet design. There are many techniques here such as spinning, curling, hydroforming, bending, punching, etc.

- Step 5: Join the sheet metal parts to form a complete battery storage cabinet. For a fully welded structure, you will use the welding technique. Other joining techniques include riveting, soldering, brazing, adhesive bonding, bolts, and nuts, among others.

- Step 6: Apply the necessary surface finishing on the sheet metal battery box enclosure. You can powder coat, paint, anodize or use a hairline surface finish.

- Step 7: Add any auxiliary accessory then subject the battery box to quality testing.

More Resources:

- Sheet Metal Fabrication

- Aluminum Sheet Metal Fabrication

- Stainless Steel Sheet Metal Fabrication

- Galvanized Steel Sheet Metal Fabrication

2. Extruding Battery Enclosure Casing

Extruded Aluminum Parts

Extrusion plays an integral role in the battery box enclosure manufacturing process. Currently, many EV manufacturers are adopting aluminum extrusion for battery casing.

During aluminum extrusion for battery housing, you will push a billet through a die. Ideally, you can extrude hollow, semi-hollow, and solid battery housing components.

Extruding aluminum battery box enclosure involves:

- Step 1 – Design the extrusion die

- Step 2 – Choose a suitable metal grade

- Step 3 – Preheat the metal

- Step 4 – On the extrusion press, let the machine push the heated billet through the dies

- Step 5 – Cool the extruded battery housing

- Step 6 – Quality inspection and applying surface finish

Apart from these, you can make battery cabinet parts through forging or casting.

More Resources:

Applications of Battery Enclosure Cabinets

EV Battery Housing

Battery enclosure cabinets play an integral role in modern industries.

From aerospace, military, automotive, medical to energy industries depend heavily on these accessories. They use enclosures in:

- Electric vehicle battery storage

- Traffic lights

- Outdoor solar lights

- Safety systems for both fire and life

- Security systems

- Power equipment

- Fiber optics systems

- Indoor lighting systems, etc.

In short, you can use these accessories anywhere and in any application. As long as you wish to protect your battery, then buying an enclosure is the best option.

Why Trust KDM as Your Battery Enclosure Manufacturer in China.

At KDMFAB, we design and manufacture many enclosures for battery. From battery box design, and fabrication, to quality inspection – our team handles every process for you.

Our team will help you choose the right material, recommend the best accessories and surface finish option for the enclosure.

With many years in the metal enclosure fabrication industry, KDM will support your OEM orders. Besides, our flexible MOQ aims to support small businesses.

Furthermore, KDM has invested in many sheet metal fabrication techniques for battery cabinets such as laser cutting, plasma cutting, CNC machining, punching machine, and material testing equipment, just to mention a few.

For all your battery enclosure boxes from China, contact us now.

More Resources:

NEMA Battery Enclosure – Source: KDM

Enclosures for Batteries – Source: KDM

Solar Battery Enclosure – Source: KDM

Top Battery Cabinet Enclosure Manufacturers in China – Source: KDM

What to Look for in Solar System Battery Cabinet Enclosure – Source: SunWize