What Is Sheet Metal Punching?

It is a process of exerting a controlled magnitude of the force on a sheet metal thereby cutting a section of the workpiece. Mostly, the process uses dies and punches as the tooling system. Under normal circumstances, the punching process will leave a hole in the sheet metal workpiece.

Benefits Of Sheet Metal Punching For Sale

Some of the benefits of sheet metal punching include:

- Ability to produce holes economically for medium and large-scale production

- Relatively affordable cutting operation as long as custom tooling is not required.

- The process of sheet metal punching is very fast and efficient.

- You can produce holes of varying shapes and sizes faster.

- Eliminates the requirement for secondary forming operations.

- It is a versatile process since you can process nearly all types of metal tolerances.

Types Of Sheet Metals For Punching Operation

Some of the types of sheet metal for punching operation include:

- Stainless steel sheet

- Iron sheet

- Aluminum sheet

- Copper sheet

- Brass sheet

- Special alloy sheets punching

Sheet Metal Punching Vs Sheet Metal Blanking

Sheet metal punching refers to a metalworking process that entails forming holes in a metal workpiece. On the other hand, sheet metal blanking is a process of metal fabrication whereby the final product is eliminated from the larger metal.

Then, the remaining material is disposed of as scrap. Additionally, in sheet metal punching, the material which is punched out is discarded and the final product is the remaining section. In sheet metal blanking, the final products tend to be removed from the larger sheet of metal and the remainder discarded as scrap.

Choosing Tooling For Sheet Metal Punching

Some of factors to consider when choosing tooling for sheet metal punching includes:

The thickness of the material: ensure the equipment you select can be used on the sheet metal without being damaged.

Price: it should remain within your budget limit while at the same time ensuring efficiency.

Easy maintenance: it should be easy to clean and maintain to ensure that it is functional for a relatively long period.

Compatibility: consider whether the tool can handle the type of material that is being used without damaging it.

Hand Powered Punching Press For Sheet Metal

They tend to be commonly used in light metalwork as these devices are simple to operate and may be mounted. They possess die sets that are interchangeable, thus allowing customization of your punches to suit specific projects at hand.

Hand-powered punch presses tend to be suited for decorative, residential, or fun undertakings and tend to be relatively affordable.

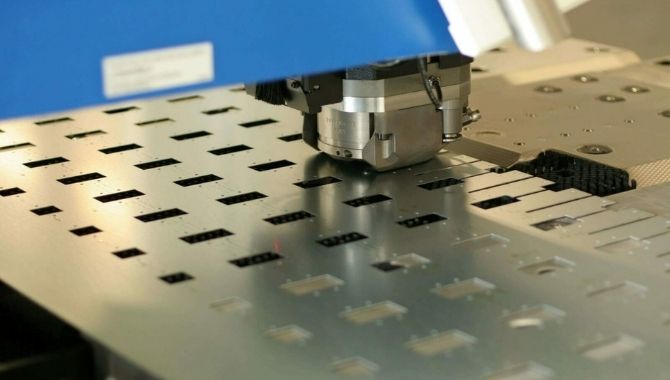

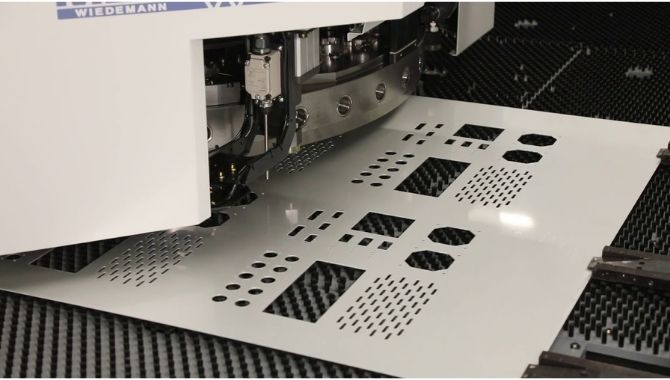

CNC Controlled Punch Press For Sheet Metal

The process begins with a CNC controller moving the table along the X and Y-axis to a position that is predetermined. Once this is done, the punching sequence is commenced.

The excess pieces are removed through the die and collected in a container for scrap once the sequence is complete. CNC-controlled punch presses tend to produce punches that are precise and at a very fast speed.

Factors Affecting Quality Of Sheet Metal Punching

Some of the factors which affect the quality of sheet metal punching include:

- Punch press affects the quality of the sheet metal. Low pressure or high pressure can cause deformities to the sheet metal.

- You should also consider the shape of the die you are using for sheet metal punching.

It should be aligned perfectly to the area of the metal you want to punch to avoid deviation.

- To ensure quality, factor in the exact size and location of the die while at the same time ensuring that the punch press is perfectly positioned.

- It is important to note that punching tools tend to be useful for a lot of strokes before they become worn out to carry out clean punches.

- Metal type: the harder the metal being punched, the more difficult it is to punch it neatly.

- The thickness of the metal which is being punched: it is hard to neatly punch very thick metals.

Manual Sheet Metal Punching Machine Vs Automatic Sheet Metal Punching Machine

It is a sheet metal punching machine that is operated using human labor and makes perfect holes every time. A manual sheet metal punching machine is manually operated by use of a long lever.

Most of them have rugged capacity of up to 137 inches of mild steel. It is available in a standard of 9 sets of punches and dies which range from 1/8 inch to 5/8-inch round.

Compared to an automatic sheet metal punching machine, a manual sheet metal punching machine is slower and suited for short runs.

It optimizes the production cycle and guarantees greater control over production times. An automatic sheet metal punching machine ensures that there is greater precision and eliminates the need for micro-unions and reworking of finished parts.

An automatic sheet metal punching machine uses either a hydraulic o an electric drive and it is automatically controlled. Its pressing force is between 200 kN and 4500 kN. It works at a very high speed of about 1400 strokes per minute and has an auto-index to ensure efficiency.

Related Articles

Sheet Metal Punching Process

The sheet metal punching process entails some steps that include:

- These machines use punches and dies.

- Normally, the metal sheet is punched from top to bottom. The punching process is guided by dies which are located at the bottom of the sheet metal.

- Here, the dies offer support to the metal and prevent it from breaking, they also assist punches in making accurate holes.

- Before the sheet metal is punched, it is secured between the dies. The dies guide the exact position or location the metal sheet is to be punched.

This basically means the die is used to guide on the exact position to punch the sheet metal.

- After the sheet metal is punched, it is then sheared to the required shape, length, and size. The cut part of the sheet metal is then collected for recycling.

- These steps are repeatedly used until the desired shape is achieved. CNC punching tends to be used to obtain cut-outs and holes of various sizes and shapes.

- This process makes it possible for manufacturers of punch and die to make sheet metal parts of any design and shape according to several needs in the market. Some of the most common geometric shapes for punched holes include rectangles, squares, and circles.

- To form indents and holes, in pieces of modern metal, sheet metal punching is conducted by use of state-of-the-art equipment.

- Sheet metal punching process may be carried out on a manual punch press although nowadays computer numerical controlled punch presses are used. CNC tends to be powered either electrically, pneumatically, or hydraulically and produces about 600 punches every minute.

Applications Of Sheet Metal Punching

Sheet metal punching is used to make large sheet metal parts such as:

- Cabinets

- Enclosures

- Car body parts

They are also used in various industries such as:

- Pharmaceutical

- Automotive

- Manufacturing

- Electronics

- textiles

Sheet Metal Punching Strategies

Some of the strategies used in sheet metal punching include:

Calculating Maximum Inside Bend Radii

There tends to be a maximum tightens within which every metal workpiece can bend before its integrity is compromised. When it is bent too tightly, it forms weak points which may easily break. However, no standard is set on how tight the bend of the inside radius should be. Therefore, this is a variable that tends to be affected by properties such as thickness and hardness of the metal workpiece.

To get the inside bend radii is a mathematical juggernaut that one should be well accustomed to. Some of the available recommendations for a perfect bend include working on the material’s tensile reduction percentage. Apart from the material’s tensile reduction, you can work on the material’s grain to get the perfect inside bend radii.

Minimizing Heat Generation To Prevent Galling

This tends to be a big problem when the material being punched compose of same composition or when punch operations are rushed. When the metal is bend, it can result to a build-up of heat due to friction. The build-up in of heat can necessitate the fusion of similar pieces of metals. This process is what is called galling. Some of the techniques which are used to reduce heat build-up and friction include:

- Application of coatings to the punch holes.

- Ensuring that there are time differences between each punch for the punch to cool down.

- Minimizing duration for contact by using back taper motions

- Make use of multiple punch heads to ensure the distribution of heat stress.

Using Laser Cutting For Making Simple Holes

Deformation is a common occurrence when it comes to sheet metal punching. It is thus important to keep checking on the punching tool. Sharpen as scheduled or replace the punching tool if any deformity or safety measure is required. Note that a defect in the punching tool will significantly affect the quality of the punch holes in your sheet metal and can also lead to unnecessary loses. Ensure that you use different cutters and punching tools when it comes to sheet metal punching. This ensures that different metals have different cutters and punching tools thus ensuring durability of your tools.

Post-punch Deburring

Sheet metal punching tends to occasionally form sharp edges and burrs. Therefore, to remove these sharp edges and burrs, manufacturers tend to use several post-forming deburring processes which include:

- Wet and dry sanding: they can use large-scale sanding machines to grind down rough edges either quickly or consistently on a sheet metal workpiece.

- Electropolishing processes: Manufacturers may create a microscopically smooth surface of the sheet metal by electropolishing strips of the surface layer.

Most of the metals which use this technique are those for the food and pharmaceutical industry. These processes assist in reducing the risk of injury when using sheet metal forms.

Sheet Metal Punching Vs Sheet Metal Shearing

Some of the differences between sheet metal punching and sheet metal shearing include:

- In sheet metal punching, the wheel tends to penetrate the metal all the way through.

On the other hand, in sheet metal shearing the excess material is trimmed from the sheet metal.

- Sheet metal punching involves the use of tools such as cutting, striking, supporting marking and measuring, and bending tools.

On the other hand, sheet metal shearing on the other hand entails the use of tools like a bench shear in slicing through the metal using a high level of precision.

- Sheet metal punching results to holes on the surface of the material being worked on while sheet metal shearing is a clean cut that does not produce holes.

Calculating Power Of Sheet Metal Punching Machine

The universal power of sheet metal punching calculated using:

- U = circumference or perimeter of the punch shape (in mm)

- s = Sheet thickness (in mm)

- Rm = tensile strength (in N/mm²)

- F = punch force in Kilonewton (10 kN = 1 metric ton)

for Stainless Steel (1.4301) 720 N/mm²

for Mild Steel (St 37) 420 N/mm²

for Aluminum (AlMg3) 220 N/mm²

f = factor between 0,5 – 0,95 when using punches with shear.

Some of the rules which should be observed to obtain better performance from matrices and punches include:

- Ensuring that the holes have a perfect diameter that meets the set standards for sheet metal punch holes.

- All the punched holes should fit perfectly to the sheet metal.

Choosing Sheet Metal Punching Tool Services

Some of the sheet metal punching tools include:

- Twists drills: it is used for a fewer number of holes. To form perfect holes, you should drill a small pilot hole using the twist drill and then twist it until you obtain the desired size of the hole.

- Stepped drill bits: used whenever a hole pattern requires multiple sizes of holes as it can be used to create different sizes of holes.

- Hole saws: it is only suited for a fewer number of holes as it is manually operated.

- Portable hand punches: it is hand operated and thus not suited for making a larger number of holes.

- Punch presses: used to form holes in sheet metal as it allows cutting multiple numbers of holes in a single cycle.

- Punch dies: they carry out cutting, shearing, blanking, punching, and piercing operations in sheet metal workpieces.

Related Resources: