Auminum Sheet for Any Industrial Need

Because of its excellent properties, the aluminum sheet is widely used for different applications including HVAC-R, buildings, automotive, construction, aerospace, shipbuilding, railways, ocean engineering, and more industries. We can provide aluminum sheets that are lightweight. It also has high ductility for easy forming into new shapes and parts. Aside from that, KDM offers an aluminum sheet with high thermal & electrical conductivity, corrosion resistance, and recyclability. If you need a first-class aluminum sheet fabrication for your customized metal parts, KDM can always help you.

Send us your inquiries today!

1100 aluminum plates that are commercially pure alloy with up to 90% aluminum content. It is formed by drawing, stamping, or spinning.

Aluminum 3003 plate features moderate strength, excellent corrosion resistance, superior weldability, machinability, and formability.

3004 aluminum sheet is non-heat treatable while providing excellent workability, corrosion resistance, high strength, and drawing characteristics.

The 3105 aluminum sheet has a semi-smooth surface and is lightweight. It is made up of 98% pure aluminum with 0.3% of the copper composition.

5005 aluminum sheets are non-heat-treatable with an anodic oxide finish, durability, decorative, and corrosion-resistant. It is ideal for architectural metalworks.

The 5052 aluminum sheets are available in different thicknesses with high elongation and strength. These are also certified by ASTM B209 and other standards.

Our 5083 aluminum sheet has good forming characteristics, is weldable, and has excellent resistance to corrosion. It is used for producing marine, cars, and other parts.

5086 aluminum sheets have good machining, saltwater resistance, and weldability making them ideal for building boats and vessel gangways application.

The 5182 aluminum sheet offers moderate strength, welding techniques, and formability making it perfect for the construction and automotive industries.

5251 Aluminum Sheet is available in different surface finishes such as mill, bright, hair line, brush, embossed, etching, sandblast, and more.

The 5754 aluminum sheets are widely used for ship exterior, tread plates, vehicle bodies, and other parts because of their high strength, excellent machinability, and corrosion resistance.

6016 Aluminum Sheets are heat treatable alloy with high strength superior machinability and corrosion resistance mostly used for automotive industry applications.

Our aluminum 6061 sheets are guaranteed to have an excellent strength-to-weight ratio, easy to weld, superior machinability, and corrosion resistance.

KDM 6082 aluminum sheets are widely used for producing different parts such as trusses, automotive parts, milk churns, bridges, and more.

6181 Aluminum Sheets are heat-treatable alloys with high strength, excellent corrosion resistance, a wide range of surface finishes, and machinability.

Thickness Range KDM Can Custom

Custom Aluminum Sheet for Any Industry Use

Features of Aluminum Sheet

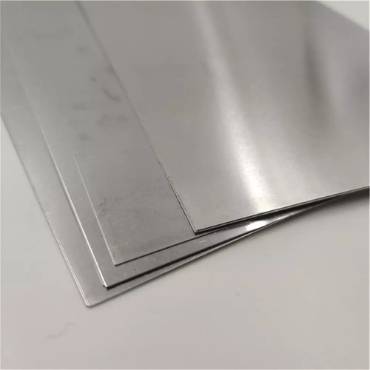

KDM aluminum sheets have high ductility. It varies in different thickness and can be very thin according to your requirements.

We offer custom aluminum sheet that features high malleability. It can be bent or shaped easily according to your request.

Our aluminum sheets are integrated with self-protecting oxide layer that makes it highly resistance to corrosion and rust.

Because of its excellent physical properties, our aluminum sheets are widely used for construction, automotive, and aerospace industries.

Custom Aluminum Sheet Cutting

KDM has advanced cutting technology including laser and waterjet.

Laser Cutting. Laser cutting technology is ideal for cutting 30mm thickness of aluminum sheets. It provides less deformation, less material heating, efficiency, and faster cutting. Laser cutting also offers excellent precision and accuracy for cutting complex geometries.

Waterjet Cutting. Aluminum sheet water jet cutting is commonly used for small volume cutting that needs high precision. It is capable of cutting up to 300mm aluminum sheets. This cutting process involves a combination of abrasives and water at high speed to cut the metal.

Custom Aluminum Sheet Welding

KDM offers different aluminum sheet welding processes including:

TIG Welding. This welding process uses alternating current for thinner aluminum sheets up 2mm.

MIG Welding. It is commonly used for thicker aluminum sheets. This welding process uses a torch to create a high melting rate.

The plasma welding process uses a direct current to introduce heat into the sheets in an orderly manner.

Custom Aluminum Sheet Bending

Because of the softness, lightweight, and malleability of aluminum sheets, they can be easily bent without cracking or breaking. This process is used for forming the sheets into the desired shape. Below are some methods of our bending process:

- V-Bending

- Bottoming

- Air Bending

- Coining

- U-Bending

- Step Bending

Custom Aluminum Sheet Stamping

Aluminum stamping is used for transforming aluminum sheet metals into specific shapes. Stamping uses cold forming to create a variety of complex three-dimensional shapes. Aluminum sheet metal stamping includes:

- Aluminum sheet metal blanking

- Aluminum sheet metal punching

- Aluminum sheet metal threading

- Aluminum sheet deep-drawing

Surface Treatment & Optimization of Aluminum Sheets

KDM is an expert in custom aluminum sheet fabrication for different industries such as automotive, aerospace, and more. We provide different aluminum sheet surface treatments to improve its quality and appearance. Our range of surface treatments includes:

Aluminum Anodizing

Aluminum sheet metal materials are perfect for the anodizing process. This surface treatment is an electrochemical process that can provide more anodic oxide finish, corrosion resistance, durability, and durability to the aluminum sheets.

Aluminum Wire Drawing

Aluminum wire drawing is commonly applied for aluminum sheet parts such as musical instruments, paper clips, cables, springs, spokes, and more. It provides increased speed, cleaner wire, better control, heat removal, easy filtration, and more advantages.

Aluminum Sandblasting

We offer aluminum sandblasting to propel fine particles of abrasive aluminum sheet metals. This process is commonly done before painting.

Aluminum Polishing

KDM uses abrasives and physical tools for aluminum polishing. This process is used for removing flaws on an aluminum sheet such as pits, scratches, grinding lines, and more. It also creates a mirror-like surface for the aluminum sheet.

Aluminum Powder Coating

Powder coating is a surface treatment type that gives extra corrosion resistance and aesthetic colors to the aluminum sheet. Benefits of KDM aluminum powder coating include hardness, durability, visual appeal, cost-effectiveness, and being environmentally friendly.

KDM Custom Aluminum Sheet

KDM offers a wide range of aluminum sheets including:

- Perforated aluminum sheets

- Chequered aluminum sheets

- Anodized aluminum sheets

- Composite aluminum sheets

- Brushed aluminum sheets, and more

KDM can also customize different aluminum sheets according to your requirements.

Because of its excellent physical and mechanical properties, custom aluminum sheets are widely used for applications including:

- Roofing

- Artistic ceilings

- Balconies

- Aluminum panels, and more

Contact us for your customized aluminum sheet needs!

More Parts We Made for Our Clients

We use aluminum sheet metals for producing aluminum front panels with lightweight, impact resistance, and readability. It comes with finishes such as gloss, satin, and matte.

KDM uses aluminum sheets for billet aluminum plate production. Our billet aluminum plates are guaranteed to have high purity, surface quality, stability, and high performance.

We offer aluminum fuel tank fabrication that provides corrosion resistance, easy installations, durability, and customization. These are produced using aluminum sheet metal stamping, bending, forming, and more.

We offer cast aluminum letters with different styles and colors of finishes and fonts. These are suitable for outdoor and indoor decorative applications. It is also ideal for any sign projects.

KDM uses different grades of aluminum sheets for metal box fabrication. We assure high accuracy, precision, optimized structural performance, and customized sizes according to your needs.

KDM offers high-quality metal nameplates that are manufactured using different grades of aluminum shapes. These are guaranteed to have sturdiness, lightweight, glossy finish, and anti-rust properties.