24/7 Online Service

KDM guarantees a fast response and 24/7 reply to your inquiries, e-mails, or calls.

Fast Delivery

We offer fast delivery of your aluminum billet plate within 10 to 15 days.

Low MOQ Support

KDM offers low MOQ of your aluminum billet plate order to support your business.

Billet Aluminum Plate

KDM manufactures aluminum billets that are widely used for forging or extrusion of aluminum. It is produced using different processes such as melting, slag removal, and more. We guarantee high-quality billet aluminum plates for your applications.

- Uniformity and stability of performance

- High purity

- Superior metallurgical quality

- Excellent surface quality

- Customized based on your requirement

KDM Featured Billet Aluminum Plates

Our sheet metal aluminum thick plates are available in 5052 aluminum grades. These are rust-proof, high-strength, and anti-fatigue. It has mill finished, embossed, and more surface finish. These are also suitable for rivets, vehicles, hard products, etc.

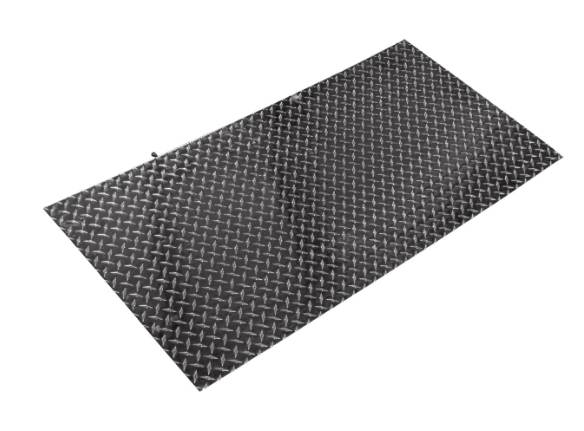

The aluminum anti-slip plates are available in 6000 series aluminum grades. It is ideal for diamond plate, checker plate, etc. This comes with mill surface finish and customized thickness and width.

Our laser cutting aluminum plates are ideal for motorcycle parts, bike parts, etc. It is available in 6000 series, Alu7075-T6, and more. These are processed through laser cutting with customized sizes and surface treatments.

We manufacture precision billet aluminum plate parts up to 0.01 to 0.05mm tolerance. It is available in custom surface finish. These are processed through CNC machining with customized dimension and sizes.

Our custom 6061 aluminum billet plates are made from 6061-T6, 5052, 6063, etc. These are available in chrome, nickel-plated, and more. We offer customizable with logo and low minimum order quantity.

KDM 6061-T6 aluminum sheet alloy plates are available up to 0.6 to 450mm thickness. It has a brushed surface finish, customized sizes, and dimensions. These are also EN485-2008 certified

How We Take Care of Your Order

- Our Factory

Billet Aluminum Plates for Different Applications

Automotive

Aerospace

Packaging

Construction

Electrical

Electronics

Engineering

Industrial

KDM Billet Aluminum Plate Advantages

We assure that all our aluminum billet plates have high strength for different applications. It has a grain structure that improves the overall strength of the aluminum plate.

Through our fabrication services, we can manufacture billet aluminum plates faster. Thus, we can offer high-volume production for your orders.

KDM offers low-cost billet aluminum plates fabrication with tight tolerances and high precision through forging method.

KDM manufactures aluminum billet plates with high extrudability, surface quality, superior mechanical properties, and excellent physical properties.

Our aluminum billet plates are manufactured for different applications including engineering, aviation, transport, buildings, automotive, and more.

You can purchase our billet plates that are made from different aluminum grades such as 1060 aluminum plate, 1100 aluminum sheet, 6000 series, 5052, and more.

KDM Billet Aluminum Plate Process

KDM manufactures billet aluminum plates through a hot-rolling, extrusion, or continuous casting process. Aluminum billets are formed using intense pressure after the impurities are removed. The shape or size of the aluminum billet plate will depend according to your requirements.

We can customize the billet aluminum plate fabrication process to meet the different industries such as electronics, automotive, aerospace, and more.

Send us your inquiries today!

“I found the best aluminum billet plates at KDM. All the plates are high-quality and easy to machine. Plus, the services are also great. I purchased these plates at KDM with very affordable price.”

“I highly recommend KDM if you are looking for a high-quality aluminum billet plate. I purchased these plates with excellent mechanical properties. I also admired KDM services and approachable personnel.”ummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries"

“The billet aluminum plates have great quality. The packaging is also high-quality. Their services are superb. Five stars for KDM!”

Our Services

Quality Guarantee

KDM prioritizes the quality of the products and satisfaction of our customers. We provide the most satisfactory services and products.

Product Quality

KDM provide one-stop solution in billet aluminum plate from design, material selection, development, production, and sales.

Customization

We can manufacture billet aluminum plates according to your drawings, samples, and OEM requirements. KDM also provides design services.

Quality Control

KDM has a strict quality control management that strictly monitors every billet aluminum plates before, during, and after production.

Related Resources

This article will help you to have a better understanding about billet aluminum plates, how is it manufactured, and what it is used for.

Forging and casting methods are used for the production of billet aluminum plates. Learn which method is better and cost-effective.

A range of aluminum grades are used to produce billet plates. Know more about different grades for aluminum for billet plates production.