Fabricating AC sheet metal parts can be an overwhelming task without the right information.

This 6-step guide highlights all the critical factors to consider during the AC Sheet metal fabrication process.

Whether you want to adopt the right fabrication technique, choose a material, or assemble AC parts– all information you are looking for is right here.

Let’s dive right in.

Step 1: AC Sheet Metal Design Process

Even before you start designing the AC systems, you must know the exact part you want. Remember, an AC system is a very specific component in the heating, ventilation, and air conditioning system (HVAC system).

So ideally, you may not fabricate all parts of an air conditioner – the focus will be on parts made from sheet metal. There are many options available in the market.

You can talk of:

- Portable air conditioner systems

- Multi-split air conditioner

- Ducted air conditioner

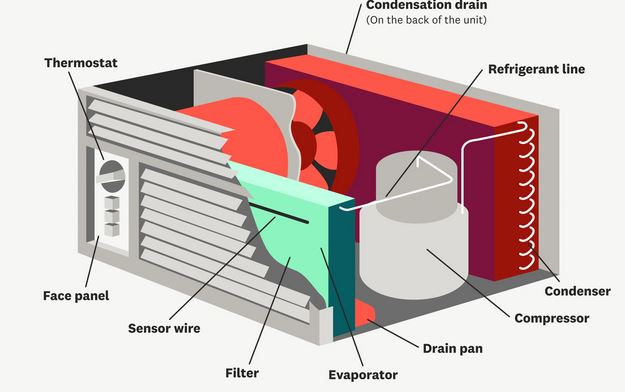

An AC system is an assembly of various metallic and non-metallic parts. Again, the AC sheet metal fabrication process will vary depending on the specific part you wish to make.

Among the key parts, you can fabricate include:

- AC Casing

- Installation or mounting brackets

- Fans parts

- Window frame

- Ventilation systems

Therefore, you must design every section according to the air conditioner requirements.

The best part is, sheet metal fabrication is a versatile process. You can use either one technique or a combination of two techniques.

Important things to note during the AC sheet metal design process are:

- Size – you can opt for custom dimensions

- Part type and configurations

- Heating and cooling source

- Installation requirements

With this, you can choose an appropriate CAD software to design your AC sheet metal parts. When you work with AC sheet metal fabricators from China, they will help you design the best HVAC systems.

Moreover, even with the AC sheet metal design, they must comply with certain requirements:

- Airflow characteristics

- Expected pressure within the HVAC system

- Possible losses due to the HVAC system operation

- AC terminal units

- Ductwork configurations

- Legal requirements

Once you specify all these, it is now time to design the AC sheet metal. Whether it is a whole section or just a small part – you will design it here.

Note: A good AC sheet metal design will translate to a high-quality product. Therefore, ensure the design is clear, easy to understand and dimensions are accurate.

Once, you have the design, choose the right AC material.

More Resources:

- Air Conditioning – Source: Science Direct

- Heating, Ventilation, and Air Conditioning System – Source: Wikipedia

- How Air Conditioners Work – Source: How Stuff Work

Step 2: Best Material for AC Sheet Metal

I know probably, you are wondering which material to go for in AC sheet metal fabrications. Well, it is important to choose popular materials such as;

- Aluminum

- Galvanized steel or,

- Stainless steel

However, in case the AC system has special design requirements, then you may consider:

- Copper

- Magnesium or,

- Brass

More importantly, you should consider the cost implications. Besides, they may not be suitable for all HVAC fabrication processes.

Again, of significance during the HVAC manufacturing process, is the material properties. Let’s summarize these in the table below:

| Material for AC Fabrication | Material Properties |

| Aluminum | · Superior corrosion resistance · Lightweight · Durable · Many alloy grades are available for fabricating air conditioner parts · Easy to fabricate – you can easily form and weld certain alloy grades · Allows for numerous surface finishes such as painting and powder coating |

| Galvanized steel | · Galvanization makes steel rust resistant · Durable · Forming and fabricating are easy · Excellent corrosion resistance |

| Stainless steel | · Available in numerous stainless steel grades for fabricating different air conditioner parts · Excellent corrosion resistance properties even in salty water environments · Numerous surface finishes are available · Durable · Better mechanical properties even in extremely cold environments |

More Resources:

- Sheet Metal Fabrication – Source: KDM

Step 3: Cutting Material for AC Sheet Metal Fabrication

You will cut sheet metal from the blank material. Of course, it will depend on the specifications you want to make.

Again, there are various cutting techniques when it comes to the AC sheet metal fabrication process. You can consider:

- Plasma sheet metal cutting

- Laser sheet metal cutting

- Piercing

- Waterjet cutting

- Punching

For instance, to make the casing, you can use the laser cutter. However, for aluminum, you should use a fiber laser cutter.

Additionally, you can make holes in the casing through punching or piecing techniques.

More Resources:

- Aluminum Laser Cutting – Source: KDMFAB

- Plasma Cutting – Source: TWI

- Waterjet Cutting – Source: Techni

Step 4: Forming Material for AC Sheet Metal Fabrication

There are many techniques you can use to deform sheet metal into a suitable AC design. Take for instance, an AC casing resembles the normal metal enclosures.

Depending on the AC design, may have sharp or curved bends. Among the most popular sheet metal forming techniques for the AC manufacturing process are:

- Bending

- Stretch forming

- Hydroforming

- Embossing

More Resources:

- Metal Bending – Source: KDM

- Stretch Forming – Source: Open Learn

- Hydroforming – Source: Wikipedia

- Embossing – Source: Wikipedia

Step 5: Assembling AC Sheet Metal Parts

At this stage, you will assemble the various AC parts to make a complete air conditioner system. That is, you will assemble the AC casing.

Additionally, you will attach other accessories such as brackets, mounting units, doors, ventilation systems, etc. For this, you may consider these sheet metal assembly techniques:

- Welding

- Riveting

At the end of this process, you will have a complete air conditioner metallic structure. From here, you can attach other accessories.

- Riveting for Sheet Metal Assembly – Source: KDM

- Sheet Metal Assembly Techniques – Source: KDM

Step 6: Applying Surface Finish on Fabricated AC Sheet Metal Parts

Once you have a fully fabricated AC sheet metal part. You will apply a suitable surface finish. This may include:

- Painting

- Powder coating

- Sandblasting

- Polishing, etc.

More Resources:

Bonus: The AC sheet metal fabrication process is a growing industry today. You can make many parts including:

- Sheet metal AC Covers

- HVAC duct systems

- Sheet metal AC covers

- AC sheet metal support brackets

- Corner AC brackets

- Sheet metal mounting plate

- Lever arms for AC

- Sheet metal AC contactor

- Sheet metal AC Vents

KDM AC Sheet Metal Fabrication Capability

At KDM, we are a leading sheet metal fabricator for AC parts in China. We design and fabricate all air conditioner systems to your unique specifications and requirements.

KDM AC metal sheets guarantee optimal air flow, they are durable and easy to adapt to most demanding HVAC situations.

With years of experience in AC sheet metal fabrication, the company has adopted a mechanism to reduce fabrication costs, while guaranteeing 100% product quality.

We work with many global HVAC systems companies through our OEM support. Contact KDM today for all your custom AC sheet metal fabrication needs.