Without the right information and tools, polishing aluminum can be a nightmare. A reason this guide explores all vital steps, tools, and benefits of polishing aluminum.

So, before starting your next project, read this guide.

What is Metal Polishing?

Metal polishing is the general term describing the process of cleaning and freeing metal surfaces of defects. This process is important for better functioning and the cosmetic value of metal parts.

Therefore, aluminum polishing is a process that cleans and smoothens aluminum metal surfaces.

Benefits of Polished Aluminum

There are many reasons why you should consider polishing aluminum surfaces:

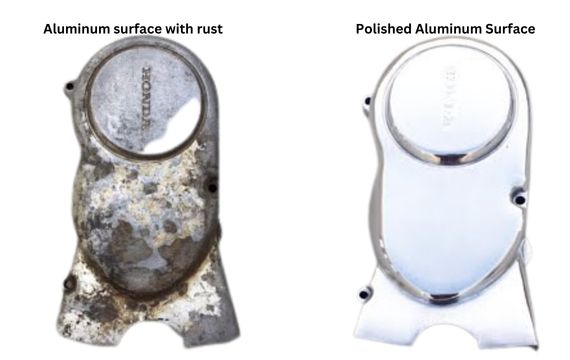

- Polished aluminum offers a perfect cosmetic appearance for your applications, giving them a beautiful mirror finish look.

- Polished aluminum surfaces are more durable

- It reduces particle adhesion and rough surface hence making cleaning and maintenance easy

- You can easily get reflective surfaces

- Polishing helps to remove stains on the surface.

Best Tools for Polishing Aluminum

Rotary polisher: If you are an expert you use a fixed speed polisher type. For beginners, a variable speed polisher is recommended.

Random orbital sander: The tool used for the sanding step during aluminum polishing process.

Angle grinder: An angle grinder is used for sanding the corners or circular parts of an aluminum metal surface.

Buffing rake: Buffing rakes are used for raking out stuck metal polish from the wheel meant for buffing.

Buffing wheels: These are the tools used for buffing the aluminum surface after sanding and application of polish.

Without these tools, you cannot carry out any polishing activities on aluminum or other metals.

Step-by-Step Aluminum Polishing Process

Aluminum polishing is a systematic process involving many processes. Each process plays an integral role in achieving smooth and highly reflective surface.

With the polishing tools and accessories, you can follow these steps:

Step 1: Aluminum Surface Cleaning

Cleaning aluminum surface is the first stage.

First, use a wet cloth or sponge soaked in a solution of water and mild utensil soap. This is suitable for projects that are not bulky. You may need commercial cleaners where productions are done in larger quantities.

In case aluminum has grease or oil, you will require special degreaser. Additionally, removal of stubborn grime needs a screwdriver or wire brush made of stainless steel.

After cleaning, give it thorough rinsing and drying before moving to the next process.

Step 2: Sanding Aluminum

Aluminum sanding is critical during the polishing process. This is because you cannot get that shiny, smooth and mirror-like surface if you don’t sand your metal part properly. Most times, by just looking at your part, you may think that it’s already very smooth.

However, under a microscope you can be able to see how rough and uneven it is.

Important to note is that, you can never get a completely even surface for your aluminum part. But even so, you should try to get an even surface.

Sanding aluminum surface can be challenging without proper information. First, you should start with a rough sand paper.

.Depending on how deep your gouges are, you may decide to use a grit abrasive of 320 or below.

Progressively, move to finer sandpaper – say from 400 grit to 600 grit.

You need to understand that some expert polishers can use up to 1500 grit. You can either use power tools or hand depending on your part sizes.

Step 3: Buffing Aluminum

Buffing is a critical processing during aluminum polishing. Usually, buffing brings the required reflective surface finish.

You will use special aluminum polish. Then apply the polish while spreading in a circular motion. Depending on the nature of the surface, you can add more buffing compound.

Once the process is complete, remove all polishing compound from the surface.

Ways to Polish Aluminum

Polishing aluminum can be achieved three simple ways depending on the needs and applications of your aluminum parts. The three main ways of polishing aluminum are described in the table below.

| How to Polish Aluminum | Description |

| Polish Aluminum by Hand | · Recommended for smaller projects. · Suitable for aluminum parts that are dull but without oxidation, pitting, burns or rust. · This can be achieved through the use of a simple microfiber applicator and hand polish. · It is a good choice for maintenance purposes. |

| Dual Action Technique | · If offer faster and accurate aluminum polishing technique · The process uses polishing compound alongside microfiber or foam pads · You can use the technique on flat aluminum sections without rust, oxidized layer or pitted sections |

| Rotary Polishing Tool | · This is the recommended method for aluminum surfaces that are dull and completely oxide, pitted, rusted or burned. You will need polishing or sanding wheels for this method to work. |

Applications of Aluminum Polishing

Just like other valued and highly demanded metals in the manufacturing industry, polished aluminum has various applications. Some of these applications are discussed below.

- Polished aluminum is definitely needed in applications that require quality, smooth reflective surfaces for parts. Cookware and kitchenware applications need polished aluminum because it is durable and resistant to rust.

- Within the construction industry interior design, doors, windows and other fittings are done using polished aluminum.

- Hospitals and various medical settings use polished aluminum for various application kits because of its hygiene properties.

- Metal parts of automobiles like rim, boat are designed using polished aluminum parts for decorative purposes and also for durability.

- Other applications may include making of items like mirrors due to its mirror-like properties.

Conclusion

From the discussion above, you can come to the conclusion that polished aluminum is more beneficial than the unpolished one.

Again, you can only get quality polished aluminum surface by using the right compounds and equipment.

More Resources:

Polishing Aluminum – Source: Empire Abrassives

How to Polish Aluminum – Source: KOW

Sheet Metal Surface Finishing – Source: KDM

Polish Aluminum – Source: Travers

Polishing Aluminum Material – Source: Instructables

Metal Surface Treatment – Source: KDM