During aluminum bending, you will transform the material into various shapes using mechanical force.

This guide looks at fundamental aspects to consider when bending aluminum such as suitable alloys, factors affecting bending process, bending techniques, to application.

So, before starting your next project, read this guide.

Factors Affecting Aluminum Bending Process

Aluminum Material Formability

Formability describes aluminum’s ability to bend without experiencing any cracks or breakages.

Aluminum alloys have good formability, which makes them good materials to bend.

However, different aluminum alloys have varying levels of formability. In fact, some alloys may be difficult to bend than others.

Level of Elongation

Elongation refers to the extent aluminum can stretch before braking. Aluminum alloys with a higher level of elongation are generally easier to bend than those with a lower level of elongation.

Bend Radius and Aluminum Thickness

Materials thickness determines the degree of bending.

Also, it will determine the bending radius of the aluminum alloy. This same concept is applicable to the aluminum alloy.

Thicker aluminum and smaller bend radii will require more force to bend. On the other hand thinner aluminum and larger bend radii will be easier to bend.

Best Aluminum Alloys for Bending Process

Examples of aluminum alloys that you can bend easily are:

3003 Series Aluminum Alloy

The 3003 aluminum alloy series is one of the most widely used alloy. Manganese element is mostly present in this alloy.

In fact, you can twist this aluminum alloy without necessarily heating it to get a suitable shape. In addition, it has suitable characteristics that make it easy to form.

You can use this alloy in applications such as:

- Roofing

- Chemical machinery

- Storage tanks

- Sidings

5052 Series Aluminum Alloy

This version of aluminum alloy has more magnesium content in it. Aluminum alloy 5052 is stronger than aluminum alloy 3003.

This makes it suitable for applications that require more rigidity since it can retain its shape after bending.

Besides, aluminum alloy 5052 is suitable for use in salty environments. It exhibits greater resistance to salt water. Aluminum alloy 5052 finds its application in the following areas:

- Hardware signage

- Marine tool

- Medical equipment

- Hydraulic tubes

6061 Series Aluminum alloy

6061 is the most rigid form of aluminum compared to aluminum alloy 5052 and 3003. Its main composition entails silicon and magnesium.

In essence, this rigidity means bending the alloy will be a difficult task.

Aluminum alloy 6061 finds its applications in the following areas:

- Aerospace industries

- Automotive industries

- Structural components

More Resources:

6061 aluminum bending – Source: KDMFAB

2024 aluminum bending -Source: KDMFAB

7075 aluminum bending – Source: KDMFAB

Temper to Use When Bending Aluminum

Tempering changes the mechanical properties of aluminum alloy. Here are some indications that will help you understand the tempering of aluminum:

- ‘T’ to mean that you have treated it thermally

- ‘H’ means the stain is hardened

- ‘O’ means annealed aluminum alloy

- ‘F’ means it has undergone fabrication

Aluminum alloys are available in different tempers, ranging from:

- Soft and pliable to,

- Hard and brittle

In addition, softer tempered aluminum alloys tend to spring back after a while compared to hard tempered aluminum.

How to Prevent Breaking/Cracking when Bending Aluminum

Some tips that will help you include:

- Using the appropriate equipment for the job: Make sure you are using the right metal bending equipment or machine

- Using lubricant: Applying lubrication to the area being bent can help reduce the amount of force needed and prevent cracking.

- Pre-heating the aluminum: Pre-heating the aluminum can make it easier to bend and reduce the risk of cracking.

- Clamping: Clamping the aluminum in place before bending can help ensure a clean, accurate bend.

Aluminum Bending Methods

When it comes to bending aluminum, there are many techniques you can use depending the material cross-section.

Whether you wish to bend aluminum sheet, tube, pipe or bar – it is important to adopt an efficient and reliable technique.

Some common options you can consider here are:

Press Brake Bending Aluminum

This method involves using a press brake machine to apply mechanical force to shape the aluminum.

How Press Break Bending Aluminum Works

- The operator positions the aluminum between the punch and die.

- Afterward, they set the desired bend angle and depth.

- They then activate the press brake machine.

- Finally, the punch applies pressure to the aluminum, bending it around the die.

Benefits of Press Break Bending Aluminum

Press brake bending is precise, fast, and can produce consistent, high-quality bends. It is also suitable for bending large, thick pieces of aluminum.

Disadvantages of Press Break Bending Aluminum

Press brake bending requires specialized equipment, which can be expensive to purchase or operate. It may also not be suitable for very small or thin pieces of aluminum.

Roll Bending Aluminum

This method involves using rolls to shape the aluminum into the desired shape.

How Aluminum Roll Bending Works

- First, the operator positions the aluminum between the rolls.

- Thereafter, the set the desired bend angle and depth.

- The operator activates the roll bending machine.

- Finally, the aluminum is passed through the rolls, which apply pressure and bend the aluminum.

Benefits of Roll Bending Aluminum

It is fast, consistent, and produces high-quality bends. It can also bend large, thick pieces of aluminum.

Disadvantages of Roll Bending Aluminum

This process needs specialized equipment that tend to be costly to buy or operate. It may also not be suitable for very small or thin pieces of aluminum.

Ram/Push Bending Aluminum Bending Process

This method involves using a ram or push tool to apply mechanical force to bend the aluminum.

How Ram/Push Bending Aluminum Works

- The operator begins by positioning the aluminum in a jig or fixture.

- Thereafter, they will activate the ram or push tool.

- Finally, the tool applies pressure to the aluminum, bending it into the desired shape.

Benefits of Push/Ram Bending Aluminum

This process is suitable for the production of aluminum with tight bends.

Disadvantages of Ram/Push Bending Aluminum

Ram/push bending may not be suitable for large or thick pieces of aluminum.

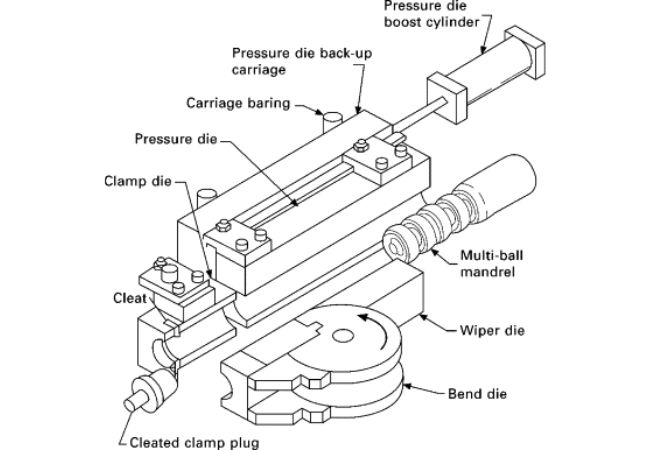

Rotary Draw Bending Aluminum

This method involves using a rotary draw bender to apply mechanical force to bend the aluminum.

How Rotary Draw Bending Aluminum Works

- Firstly, the operator positions the aluminum between the mandrel and die.

- Afterward, they will activate the rotary draw bender.

- The mandrel applies pressure to the aluminum, bending it around the die.

Benefits of Rotary Draw Bending Aluminum

The process can produce aluminum with a tight radius, accurate angles, and smooth transitions. It is also suitable for bending large, thick pieces of aluminum.

Disadvantages of Rotary Draw Bending Aluminum

It requires specialized equipment, which may mean you will spend a lot to buy and even operate. Besides, it may also not be suitable for very small or thin pieces of aluminum.

Three-Roller Bending Aluminum

This method involves using three rolls to bend the aluminum into the desired shape.

How Three-roller Bending Aluminum Works

- It begins by positioning the aluminum between the rolls.

- The operator activates the three-roller bending machine.

- Finally, the aluminum is passes through the rolls, which apply pressure and bend the aluminum.

Benefits of Three-roller Bending Aluminum

Three-roller bending is suitable for the production of architectural components or construction usages.

Disadvantages Three Roller Bending Process

This process needs unique equipment that may cost you a lot to purchase or even operate. Furthermore, it may not be suitable for very small or thin pieces of aluminum.

Compression Bending Aluminum

This method involves using a punch and die to apply mechanical force to bend the aluminum.

How Compression Bending Aluminum Works

- The operator positions the aluminum between the punch and die.

- Afterward, they will activate the compression bending machine.

- The punch applies pressure to the aluminum, bending it around the die.

Benefits of Compression Bending

This process will enable you make aluminum products whose bends on either side is similar.

Disadvantages of Compression Bending

The machine can be costly to purchase and may also not be suitable for large or thick pieces of aluminum.

Stretch Forming Aluminum

This method involves using mechanical force to stretch the aluminum into the desired shape.

How Stretch Forming Aluminum Works

- The operator positions the aluminum in the jig or fixture.

- Afterward, they activate the stretch forming machine.

- The jig or fixture applies pressure to stretch the aluminum into the desired shape.

Benefits of Stretch Forming Aluminum

In this process, you can replicate the angle of the bend. Also the tension during the process will ensure constant control on the entire aluminum length.

Disadvantages of Stretch Forming Aluminum

The need for specialized equipment makes it expensive. In addition, it may not be suited for thin and small aluminum pieces.

Hand Bending Aluminum

This method involves manually shaping the aluminum using hand tools such as pliers or hammers.

How Hand Bending Aluminum Works

- The operator positions the aluminum in the desired shape.

- They then apply force using hand tools such as pliers or hammers.

- The aluminum is bent into the desired shape.

Benefits of Hand Bending Aluminum

Hand bending is a simple and inexpensive method that does not require specialized equipment. It is also suitable for small or thin pieces of aluminum.

Disadvantages Hand Bending Aluminum

Hand bending is a slow process and may not be suitable for large or thick pieces of aluminum. Furthermore, since this method is not consistent, the final output will be different from one another.

Applications of Aluminum Bending Process

Some common applications of aluminum bending include:

- Automotive components: Aluminum is often used to make automotive parts because it is lightweight and strong. Bending is used to create car body panels, fuel tanks, and other components.

- Construction: Aluminum is used in the construction industry to make window frames, door frames, and other structural components.

- Aerospace: The aerospace industry relies heavily on aluminum because of its strength-to-weight ratio. Bending is used to create airplane wings, fuselages, and other structural components.

- Furniture: Aluminum is sometimes used to make furniture because it is lightweight and easy to work with. Bending is used to create chair frames, tables, and other furniture components.

- Electrical: The electrical industry uses aluminum to make electrical conductor bars and other components.

- Signs and Displays: Aluminum is often used to make signs and displays because it is lightweight and easy to work with.

Conclusion

Aluminum bending specialists, KDMFAB hope this guide has given you insight into what goes into the aluminum bending process.

For all aluminum bent parts from China, contact us now.

More resources:

Aluminum Sheet Metal Fabrication: Source: KDMFAB

Sheet Metal Bending – Source: KDMFAB

Factors to Consider when Bending Sheet Metal Parts – Source: KDMFAB

Aluminum Tube Fabrication – Source: KDMFAB