Bending is an important process in brass fabrication. Whether you want to bend brass tubes, brass wires, or brass wires, this guide explores all the techniques and tips for successful fabrication process.

Keep reading to learn more.

Importance of Brass Bending

To facilitate qualitative manufacturing, you need to bend the brass. This is essential to give the brass a particular shape and form.

You can turn your brass at any angle or side with multiple techniques. But it isn’t easy without sufficient knowledge and tools at hand.

Find information on techniques that you can use to bend various brass accessories on the go.

1.Brass Wire Bending or Brass Rod Bending

Brass wire refers to a wire that is long and resembles a thread. It is circular. On the other hand, the brass rod is a straight rod with a square shape.

Tools You Need

- Pair of Round Nose Pliers

- Pair of Flat Needle Nose Pliers

- Special Metal Forming Pliers

- Bending Jig

- Plywood screws

- Screw Driver

- Gas Torch

Process of Bending Brass Wire

Method 1: With Hands

First, you need to take the wire to bend the brass wire. Now consider its gauge. If the wire is thin enough, you don’t need any tool to bend the brass wire.

Simply by using your hands, you can perform bending. Hold the wire in one hand, and don’t move it. Now apply the force using your second hand smoothly to perform bending.

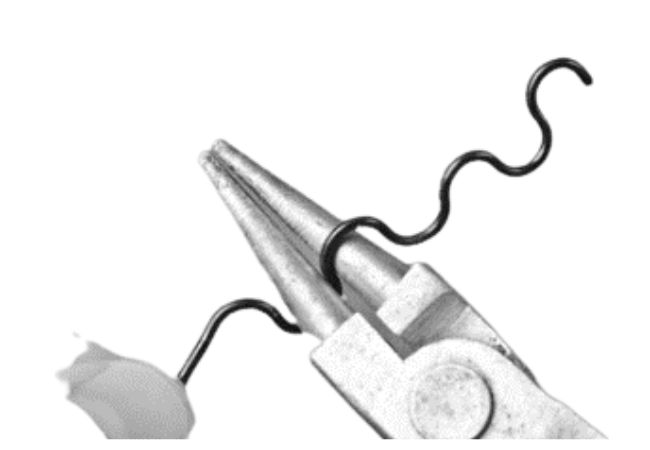

Method 2: With Pliers

If the wire is thick and of heavy gauge, you don’t need to use both hands. Pliers will serve the purpose in this regard.

Take a round nose plier and hold the wire from one end. Now use your free hand to form a bend. You can create a crimp, curve, or bend using this method.

If you want a sharp bend, then you can use both pliers. Hold both free ends of the wire with individual pliers to do so.

Now keep one stationary and move the other to form a sharp lot. Please note that round nose pliers give a curvier bend, while flat nose pliers give a sharp bend. The option exists to make use of special metal-forming pliers

2. Process of Bending Brass Rod

Method 1: Bending Jig

It would help if you used a bending jig to bend the brass rod effectively. The bending jig comprises a number of slots as well as pegs. These pegs and slots will facilitate the formation of any bend or curve shape you want.

First, you must fix the bending jig in the board to process bending. You can use a screwdriver to tighten the bending jig in the horizontal board with plywood screws. An option also exists to clamp it. The committee facilitates easy bending by bending the jig.

Then you can put your brass rod within the slots or pegs. Now you must use the force of your hands to achieve a proper bend. Moreover, this bending jig does not form any marks over the brass rod.

Method 2: Gas Torch + Brass Bending Jig

If you want to achieve a smoother finish in the bend, have a heavy gauge rod. Then use this technique. Take a gas torch and switch it on. Now take the piece of brass rod that you want to bend. Heat the rod on the gas torch for about 30 seconds.

Keep the temperature of the gas torch within the range of 5000C to 6500C. Doing so, the rod becomes softer.

After softening the rod, please pick it up with a plier and take it on the bending jig. Place the brass rod within the desired jig slot/peg. Now use your free hands and apply a little force to form a bend. Please note that hot brass rods require less hand force than cold brass.

Precautionary Measures

Working with the pliers can result in marks formation on the wires. To avoid this, you need to purchase pliers having pads. Or use mask tape and wrap it on the pliers’ jaws. This will prevent mark formation.

3. Brass Tube Bending

A brass tube is a hollow, long tube with a cylindrical form. You can use it to transfer or hold liquids as well as gases.

Tools You Need

- Metal Coil Spring

- Tube Bender

Bending Process

Method 1: Metal Coil Spring

There are chances of crushing and kinking when it comes to brass tube bending. But if you use coil metal springs, you can avoid the such phenomenon.

To begin with the process, first, you need to take a brass tube. Later take a metal coil spring. Ensure the spring coil’s diameter is slightly lower than the brass tube diameter.

Now put the coil spring inside the brass tube and take it to the section where you want to form a bend. Use both your free hands to apply a force for bend formation.

The spring coils offer support to the brass tube walls and eliminate chances for crushing. There are multiple diameter metal coil spring that exists. You can choose anyone depending on your needs.

Method 2: Tube Bender

Tube Bender is another tool that facilitates brass tube bending. For higher-quality results, you should choose this method.

The tube bender set contains multiple types of diameter tube benders. You can use anyone depending on the diameter of the brass tube you have at hand. To process the bending operation, insert the brass tube within the tube bender.

Hold the tube bender with one hand and the other to apply the force to form a bend.

Various types of tube benders can facilitate the bend at different angles. The primary grades include 0 degrees up to 180 degrees.

Precautionary Measures

To avoid lacerations while bending the tubes wear gloves. Also, use measuring tape to experience a precise bend per your applications.

4. Brass Bar Bending

You can define a bar as a piece whose length is slightly larger than its width. OR a rectangular block piece.

Tools You Need

- Vise

- Marker

- Scoring Tool (Triangular file/ Square file)

- Measuring tape

Brass Bending Bars

Method 1: For Thinner Brass Bars

If the brass bar’s thickness is slighter or low, use this method. Take a marker and measuring tape. Measure the exact point with the help of measuring tape where you want to mark. Now put a mark on the same point using a marker.

Now open the vise and place the marked end within the vise. Use your hand force to facilitate bending.

Method 2: For Thicker Brass Bars

If you have a thick brass bar, utilize this method. It isn’t easy to bend the thick brass wire as per method 1. Let’s begin with the bending process.

First, take a brass bar that you want to bend. Later take a measuring tape and measure the point where you want to bend the brass bar and mark it with a marker. Now take a scoring tool and remove some of the material from the inside.

This will help in folding the brass bar on itself. Scoring will also ensure the exact point bending where you want it to bend. You can score the bar with a triangular or square file.

Move the file from one brass bar edge to another brass bar edge. At the same time, grooving ensures the thickness of the groove is no more than half the thickness of the brass bar.

After grooving place, the bar is in a vise by exposing the scored line.

Use your hand force to bend the brass bar. Metal removal allows you to put a slighter force to process bending. You can perform soldering to ensure sufficient strength on the groove edge of the brass bar.

Precautionary Measures

While placing grooves on the bars, do not place deeper grooves, as this will result in breakage. Always wear gloves to avoid directly touching the groove part. Apply the hand force slightly and notice the bend formation. Never use a higher power initially, as this can lead to deformation. You can also place the brass bar within wooden board pieces to prevent scores or marks on the brass bar.

Brass Sheet Bending

A brass sheet refers to a sheet that has a flat and thin formation. The thicknesses of the sheet vary depending on the end application.

1. Tools You Need

- Mallet

- Hammer

- Marker

- Measuring Tape

- Vise

- Wooden Blocks

Bending Brass Sheet Metal

Method 1: For Sharp Bend

This method is effective if you aim to achieve sharp bends. To begin bending, first, place a mark on the bending point. You can measure with the measuring tape and put a mark with a marker.

Later open the vise and place two wooden blocks on either edge of the vise. Later insert your brass sheet within. Close the vise and use a hammer/ millet/ wooden block to bend the sheet precisely. Using wooden blocks will prevent the formation of scores or marks on the sheet.

Method 2: For Curve Bend

Use a roll bending machine to facilitate the curve bending brass sheet. This machine comprises three consecutive rollers that obtain power from a hydraulic press.

You must put your sheet in the rollers to achieve the curvy bend. The distance between the rollers ensures the type of curve you will achieve.

Method 3: V-Bend

To achieve the V-type bend, you can use a die and a puncher having a v shape. First, place the brass sheet over the V-shaped die. Now press the puncher against the workpiece. Doing so will help you get a V shape bend.

The puncher receives its operational power from the hydraulic system of the machine. An option exists to change the die to a square, rectangular, or irregular shape to achieve the bend you need.

Precautionary Measures

Always wear goggles and safety gloves while performing bending operations using your hydraulic machines. Utilize work boots and avoid wearing loose clothes during the bending process. Never touch the sharp bends, even if you have gloves.

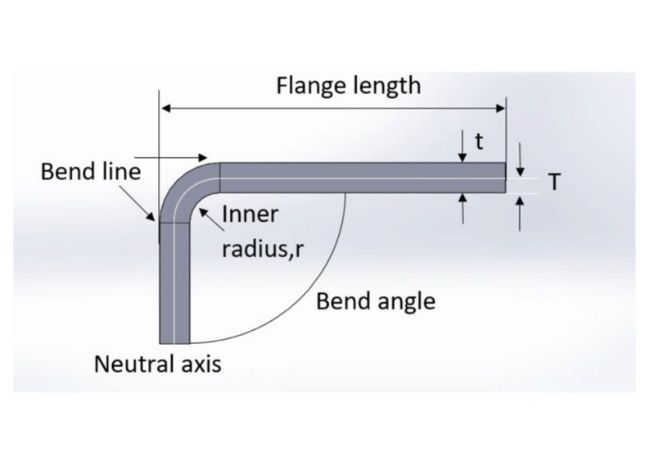

Factors Affecting The Brass Bending

A bunch of factors affects the bending in the brass. Some key factors that are worth considering are here for your reference.

Material Thickness

The thickness of the material means a greater number of molecules on a confined surface. More number of molecules means a large amount of force you need to perform the bending operation. Thinner materials do not require special tooling to perform bending functions.

Bending Angle

The essential aspect that needs your attention is the bending angle. If you don’t choose a bending angle wisely, you will experience a wrong bend. It may also lead you to experience a deformation. You can use angle measuring tools to achieve better results.

Punch Radius

Punch radius is another important factor that plays a part in deciding the end bend formation. Keep the punching tip radius below the inside bend radius. Not doing so will help you experience a poor bend.

Bending Force

The bending force also affects the type of bend you want to get. Brass material with different thicknesses requires additional force to process bending. Increasing the force above an optimum point will lead to breakage, scores, and marks on the material. Keeping this force below an optimum level prevents you from achieving a proper bend. Consider this parameter into account while bending.

Material Temperature

If the material’s temperature is high, it does not require special tooling or extra force for bend formation. While if the material temperature is lower, then it involves the use of tooling and equipment for bend formation.

Conclusion

Whether you want to bend the brass sheet, bar, wire, rod, or tube. You can do so on the go with the help of the above useful guide. Suppose you have any confusion or questions relating to brass bending.

KDMFAB team is here to help.

More Resources:

Sheet Metal Brass Fabrication – Source: KDMFAB

Brass Alloy – Source: Science Direct

Bending Brass Rod – Source: CMT

How to Bend Brass Rod – Source: The Piping Mart

How to Bend Brass – Source: Metalfy

Bending Brass Tubing – Source: The Piping Mart

Bending Brass Bar – Source: The Piping Mart

Bending Brass Sheet Metal – Source: Piping Mart

Sheet Metal Bending Parts – Source: KDMFAB

Factors to Consider when Bending Metal Parts -Source: KDM