Cable tray is a structure for supporting and organizing cables. Usually, it has another section that encloses the cables within the tray called a “cover” or “lidding” section.

That is, it covers the top section of the cable tray.

In this guide, you will learn about the different types of cable covers and how to choose a perfect option.

Let’s dive right in:

Cable Tray Cover Types

There are many criteria for classifying these covering electrical cable management systems. They vary in design depending on specific application requirements.

Let’s look at some common classification criteria:

Cable Tray Roofing Material

When it comes to fabricating cable tray enclosures, you can choose from composite, rubber, metal to plastic materials.

However, metal and composite materials remain popular in today’s industry. Therefore, they form critical classification criteria for cable tray covers.

In case you want to choose these cable tray covering based on material, you should consider the following:

| Tray Cover Type | Specification |

| Stainless steel cable tray cover | · Minimum working temperature -184°C · Those made from austenitic stainless steel are suitable for extremely cold environments · Resistant to rust · Offer good strength and extremely durable |

| Fiberglass cable tray cover | · Minimum working temperature -73°C · Can be a perfect choice for cold temperatures · Strong, durable, and easy to fabricate |

| Aluminum cable tray cover | · Minimum working temperature -129°C · Popular for lightweight design · Easy to fabricate forming any cover design · Rust resistant · Greater strength |

| Low carbon steel | · Minimum working temperature -29°C · At extremely low temperatures they become brittle · Strong and durable · Tend to be heavy therefore may require structural reinforcement |

| Galvanized steel cable tray covers | · They are rust resistant · Durable and offer unmatched performance · Suitable for most harsh environmental conditions especially outdoor |

However, it does not imply that the material classification is only limited to these four. You can choose other materials depending on the working environmental conditions.

Types of Cable Tray Covers based on Design

Depending on the cable tray cover requirements, you may have unlimited designs and options. In fact, the list can be endless.

However, we will focus on the main cable tray cover design available:

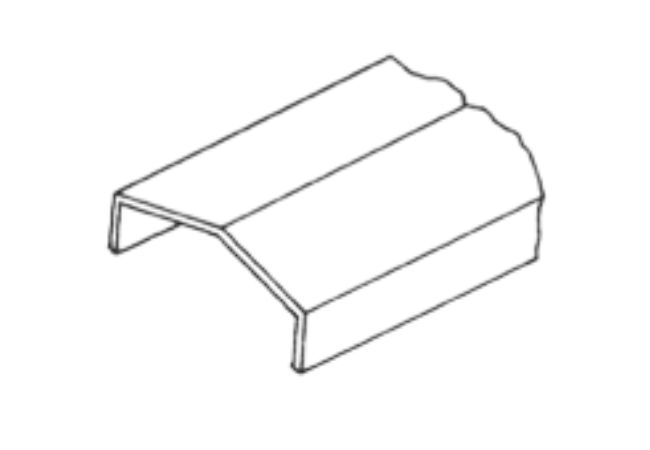

1. Dome Shaped Tray Covers

These types of covers are also referred to as Hat-shaped covers. They are ideal for applications where the enclosed cables are extending past the tray rims.

Commonly, dome-shaped covers either have a flat top or a corrugated top.

2. Flat Tray Covers

Flat tray covers differ in terms of flanges. Some flat tray covers have flanges while others lack. The inclusion of flanges is dependent on the specific application of the cover. Finally, the flat tray covers are best ideal for straight fittings.

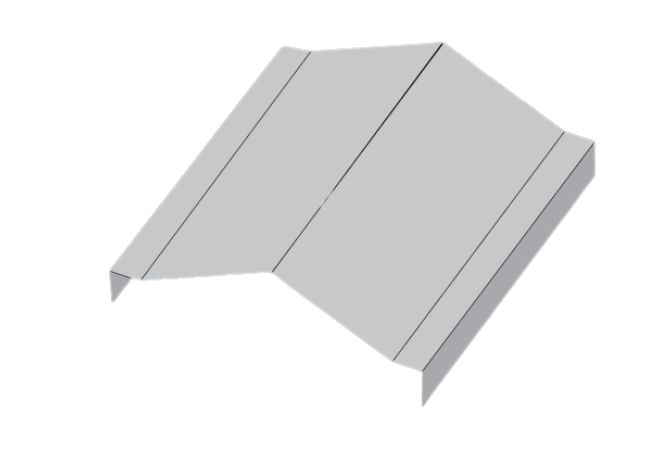

3. Peaked Tray Covers

As the name implies, the peaked tray covers form a ½ inch standard peak on the surface. Peaked tray covers are ideal when the tray is installed in a place prone to falling objects, debris, or even snow. Additionally, the peak shape prevents the accumulation of fallen materials on the tray’s surface.

4. Finned Tray Covers

Finned or louvered tray covers come in three main forms:

- Flat

- Flat-flanged

- Hat shaped.

Notably, their application is mostly in the straight sections of the tray.

5. Corrugated Tray Covers

Corrugated tray covers are manufactured from corrugated sheets. Corrugated covers are the go-to covers for both horizontal and vertical fittings.

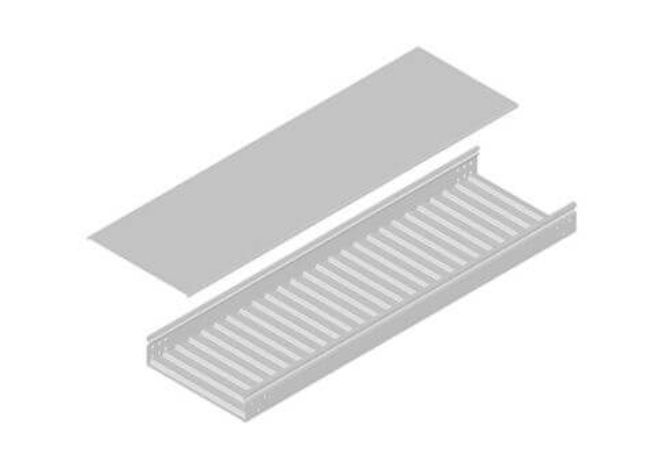

6. Ventilated or Non-Ventilated Tray Covers

A try cover may have vents – they can be in form of holes. Alternatively, they may not have vents. Remember, all the above types of tray covers can either be ventilated or not ventilated depending on the specific application.

Horizontal fittings require unventilated covers while ventilated covers are best suited for vertical fittings.

7. Perforated Cable Tray Covers

These cable try enclosures have several holes on their surface. Remember, these holes act as ventilation systems.

8. Flanged Cable Tray Cover

They have special flanges. Depending on the design, they may have peaked or flat surfaces. For easy installation, they readily slide into the cable trays.

9. Classification According to Surface Finish

There are many surface finishing options you can apply on cable trays. For example, you may have:

- Galvanized cable tray covers

- Powder-coated cable tray covers

- Painted cable tray covers

- Polished cable tray covers

- PVC cable tray cover

Classification According to Area of Application

Under this category, we have:

10. Outdoor Cable Tray Covers

They have special designs, protecting cables from harsh environmental conditions. These may include excess heat, rain, excess moisture, or possible vandalism

11. Indoor Cable Tray Covers

These accessories are specifically designed for indoor uses. Therefore, they do not have additional protective or safety features.

Apart from these, you may also want custom cable tray cover types. They will depend on your unique designs and requirements.

At KDMFAB, we can design all tray covers for all your cable systems – contact us now for any inquiries.

How to Choose Cable Tray Cover Types

When it comes to choosing the right cover for your cabling systems, you must consider certain attributes.

These may include the design, and handling capability to material selection. The best part, we have mentioned some of these variables in the first section.

So, here, we shall make a quick list for faster evaluation when buying tray cover for cables.

| No. | Cable Tray Specification to Look for | Various Cable Tray Attributes |

| 1 | Cable tray design | · There are many designs to choose from including dome, flat, peak, finned, corrugated, ventilated, perforated, and custom designs. |

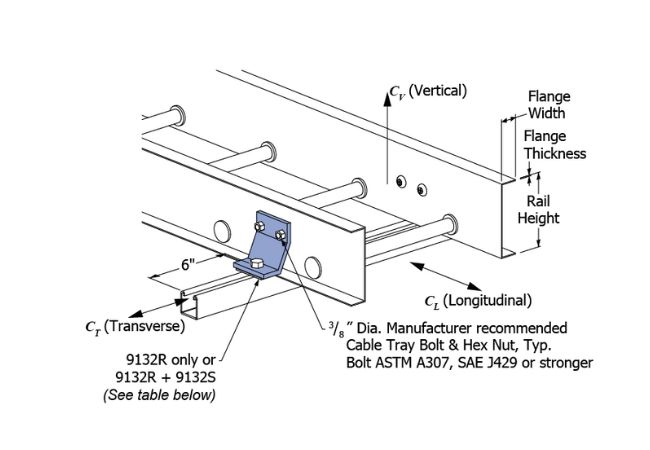

| 2 | Consider tray cover accessories | · Cable tray cover clamps · Cable tray cover clips · Cable tray cover strips, etc. |

| 3 | Cable tray cover installation requirements | · These may include the cable you want to cover, cable tray design, applications requirements |

| 4 | Material type | · Aluminum · Fiberglass, etc. |

| 5 | Cable tray cover price | · The price depends on variables such as size, design, safety requirements, etc. |

| 6 | Cabling requirements and type of cable tray | · The cover should fit perfectly on the cable tray · Choose according to the type of cables |

| 7 | Safety requirements | · Different covers for cable trays have varying degrees of protection. From fully enclosed, perforated to ventilated options |

| 8 | Cable tray installation requirement | · It depends on whether you want to install the covers for cables indoors or outdoors. · It may vary whether you wish to install the cables in high temperature, or high moisture region |

| 9 | Quality standard requirements | · Some standards control the installation of electrical systems such as NEMA, CE, IEC, UL, or IP rating. You should ensure the cable tray cover complies with these safety requirements |

What is cable tray cover hsn code?

The HSN code for cable tray cover is 73089090.

Conclusion

Ensure you choose a tray cover that fits the cable tray. The tray cover should not only protect the cables but also complement the cable tray.

More Resources:

Cable Tray – Source: Wikipedia

Cable Trays – Source: NEMA

Cable Tray Types – Source: Instrumentation

Cable Tray Selection – Source: Cable Tray Institute

Cable Tray Cover – Source: MPHUSKY

Sheet Metal Fabrication – Source: KDM