NEMA 4X and NEMA 6P are common ratings we use in many electrical systems. Ideally, these NEMA rating refers to the degree of protection a system can offer.

In this article, we will compare fundamental aspects about these ratings – from similarities, differences, level of protection to uses.

Let’s dive right in:

What is NEMA 4X?

The NEMA 4X is a rating that refers to systems with the ability to offer protection against windblown dust, splashing water, hose-directed water, and corrosion.

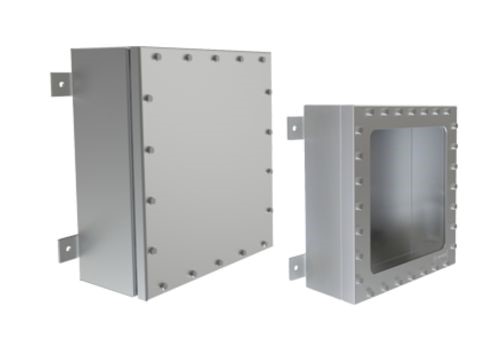

To attain this NEMA rating, your systems must feature unique construction designs. For instance, an electrical enclosure with NEMA 4X will have gasket seams.

NEMA 4X Electrical Enclosure

What is NEMA 6P?

NEMA 6P rating refers to a higher degree of protection. Systems with the rating cannot withstand prolonged submersion in water.

But still, they provide protection from water, dust, and caustic materials.

NEMA 6P Enclosure

Similarities between NEMA 4X and NEMA 6P

NEMA 4X and 6P ratings have numerous important commonalities even if they indicate variations in design construction:

- Both standards seek to protect your electrical equipment against water, dust, oil, and chemicals by use of gasketed seams and robust material construction.

- NEMA 4X and 6P enclosures resist high-pressure washdowns, temporary submersion, and cleaning techniques typical of your industrial settings like in food processing factories.

- Both standards of enclosures endure exposure inside or outdoors without deterioration over time since they are made of corrosion-resistant materials.

- You will commonly apply NEMA 4X and 6P ratings to protection of your control panels and wiring in demanding industrial settings.

- Both standards meet stringent NEMA performance specifications for dust and liquid ingress protection.

Differences between NEMA 4X and NEMA 6P

Although NEMA 4X and 6P enclosures include protective features, their designs also show notable differences:

| NEMA 4X | NEMA 6P |

| NEMA 4X aims to shield contents from splashing water from any direction as well as temporary immersion under water. | NEMA 6P focuses on resistance to washing and temporary submergence. |

| NEMA 4X enclosures endure longer submergence, requiring seals effective against high-pressure water like fire hose streams. | NEMA 6P withstands washdowns without damage. |

| NEMA 4X boxes receive additional sealing to counter corrosive effects in harsh environments like seawater atmosphere. | NEMA 6P suits mild chemical exposure. |

| NEMA 4X enclosures utilize corrosion-resistant fasteners and hardware suitable for maritime applications. | NEMA 6P hardware requires oil-tightness instead of full corrosion resistance. |

| Internal NEMA 4X box components may receive additional anti-corrosion measures since contents face immersion hazards. | NEMA 6P protects without full internal corrosion proofing. |

| You will apply NEMA 4X ratings to equipment operating continuously outdoors or in corrosive indoor areas. | NEMA 6P usually protects equipment exposed to water sprays. |

Comparing Level of Protection in NEMA 4X and NEMA 6P

In general, NEMA 4X enclosures provide you with a higher degree of protection against dust, water, and corrosion compared to NEMA 6P standards. Some key ways their protective abilities differ:

- Ingress Protection: NEMA 4X resists dust and prevents water intrusion in your electrical equipment from any direction at high pressure. NEMA 6P withstands temporary low-pressure water exposure from limited angles.

- Weather Resistance: NEMA 4X enclosures endure longer periods of submersion and resist corrosion from harsh environments like coastlines. NEMA 6P focuses on temporary submergence in cleaning runoff water.

- Sealing Integrity: NEMA 4X uses additional gasketing and sealing to inhibit water and dust at all joints, screw heads, and connections. NEMA 6P sealing meets oil-tight standards.

- Component Protection: NEMA 4X suits total immersion applications and protects internal components from corrosion effects. NEMA 6P provides functional protection during washdowns.

Comparing Uses of NEMA 4X vs NEMA 6P

NEMA 4X enclosures shield your controls for environments like:

- Water/wastewater treatment facilities

- Food production conveyor controls

- Offshore gas and oil rig components

- Exterior control panels at loading docks

NEMA 6P enclosures protect your equipment in:

- Heavy industry and factory wash-down areas

- Meat and poultry processing wash stations

- Nearby exterior tanks during cleaning

- Cooling equipment in proximity to hoses

NEMA 4X enclosure locations:

- Completely outdoor-installed control cabinets

- Corrosive environments indoors like chemical plants

NEMA 6P settings typically include:

- Interior mechanical rooms and areas near washing

- Sheltered spaces that see periodic water exposure

At KDM, we offer different systems with varying NEMA enclosures depending on customer requirements. Whether you want systems rated NEMA 4X or NEMA 6P, our team will offer proper designs advise and costing – contact us now for inquiries.