About Aluminum Front Panel

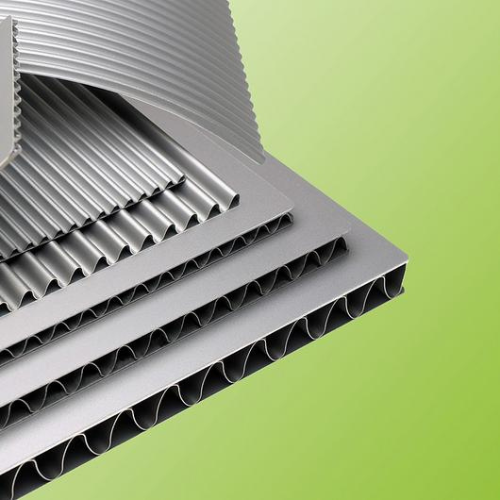

Aluminum front panel is typically used as the front-facing component of various products, devices, or equipment. These panels are commonly found in electronics, machinery, control systems, and various other applications. Aluminum is chosen for front panels due to its lightweight, durable, and corrosion-resistant properties. It can also be easily machined, engraved, or printed to display information, branding, buttons, or controls.

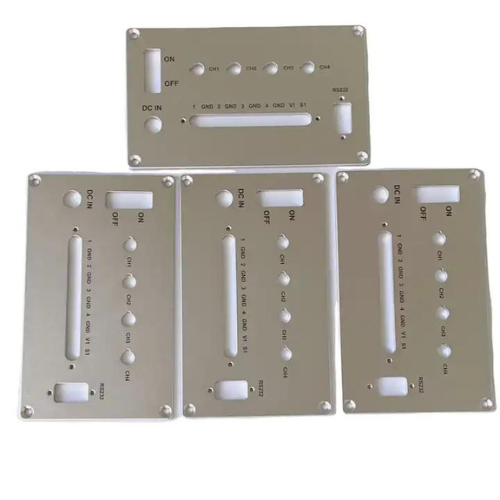

Your special needs of the aluminum front panel’s distinctive and complex dimensions can be achieved using our machining, punching, laser cutting, bending, hardware installation, riveting, and welding capabilities. We all choose photosensitive anodized aluminum as the most resilient printed aluminum base, given its suitability for harsh environmental conditions and prolonged outdoor use. For your convenience, our aluminum front panels come pre-punched and complete with all the necessary openings for mounting LEDs, displays, switches, and similar components. Numerous fonts and design elements can be printed on panel surfaces, including your corporate logo.

Aluminum Front Panels-A Proper Choice For You

- Durability: Aluminum front panels are robust and resistant to wear, making them suitable for long-lasting use, even in demanding environments.

- Corrosion Resistance: Aluminum naturally resists corrosion, ensuring the panel’s integrity in outdoor and challenging conditions.

- Lightweight: Aluminum is a lightweight material, which is beneficial for transportation and installation.

- Customizable: Front panels can be easily customized with various designs, graphics, and text for branding and functional purposes.

- Machinability: Aluminum is easy to machine, allowing for precise cuts, holes, and other modifications to meet specific requirements.

- Printability: The surface of aluminum panels can be printed with graphics and information for user interfaces and branding.

- Versatility: Aluminum front panels can incorporate components like buttons, switches, displays, and more, making them adaptable for various applications.

- Heat Dissipation: Aluminum’s thermal conductivity aids in heat dissipation in equipment and electronic enclosures.

- Weather Resistance: Aluminum panels can withstand exposure to a wide range of weather conditions without degrading.

- Professional Appearance: They offer a sleek and modern appearance, enhancing the aesthetics of the equipment or device.

- Protection: Front panels safeguard internal components from physical damage, dust, and moisture.

- Custom Apertures: Panels can be pre-punched or machined to include openings for LEDs, displays, switches, and other components.

- Logo Integration: Company logos and branding elements can be included in the panel design.

These features make aluminum front panels a popular choice for a wide range of industries and applications, including electronics, telecommunications, industrial machinery, and more.

Where to Use Aluminum Front Panels

Aluminum front panels find a wide range of applications in various industries due to their durability, versatility, and aesthetic appeal. Some common applications of aluminum front panels include:

- Electronics and Control Panels: Aluminum front panels are often used in the electronics industry for the front covers of control panels, circuit enclosures, and instrumentation displays.

- Consumer Electronics: They are used in consumer products like audio equipment, amplifiers, computer cases, and home theater systems.

- Industrial Machinery: Aluminum front panels are employed in machinery and equipment as user interfaces, displaying information, controls, and indicators.

- Telecommunications: They can be found in telecom equipment, network cabinets, and server racks for housing and displaying network components.

- Medical Devices: Aluminum front panels are used in various medical equipment, including diagnostic devices, monitoring systems, and medical instruments.

- Automotive: They can be found in vehicle control systems, dashboards, and infotainment systems.

- Aerospace and Aviation: Aluminum front panels are used in aircraft and aerospace applications, including cockpit displays and control interfaces.

- Marine Equipment: In the marine industry, they are used in ship control panels, navigation displays, and communication systems.

- Scientific Instruments: They can be found in laboratory equipment, analytical instruments, and scientific measurement devices.

- Military and Defense: Aluminum front panels are used in military equipment, communication systems, and defense technology.

- Audiovisual Equipment: They are employed in audio and video equipment, including amplifiers, mixers, and signal processing devices.

- Environmental Monitoring: In environmental monitoring systems and weather stations, they serve as control interfaces and display screens.

- Industrial Control: In manufacturing and process control systems, aluminum front panels help monitor and control equipment and processes.

- Retail and Vending Machines: They are used in point-of-sale terminals, kiosks, and vending machines.

- Information Kiosks: In public spaces and transportation hubs, aluminum front panels are used in information kiosks and ticket machines.

- Lab and Test Equipment: They are employed in laboratory equipment, test instruments, and measuring devices.

- Energy and Utilities: In the energy sector, they are used in control systems for power generation, distribution, and monitoring.

- Broadcast and Media: Aluminum front panels are found in broadcasting equipment, studio consoles, and media control systems.

- Custom Enclosures: They can be used for creating custom enclosures for specialized equipment and machinery.

Aluminum front panels are highly appreciated for their blend of practicality, visual appeal, and resilience, rendering them a perfect option for a diverse array of industrial and business uses.

KDM-Customization Expert

We offer a variety of surface finishes for aluminum front panels, including options like matte, satin, #4, gloss, and more.

We have black graphics on silver background or silver graphics on black background in stock and many other colors for you to choose.

Advanced tooling enables precise fabrication capabilities, such as milling, countersinking and counterboring holes, bending and forming, stud insertion, stand-offs, permanent pressure-sensitive adhesives, and more.