It’s completely understandable if you’ve never heard about a band saw before. But, while they mostly work in industrial settings, band saws have the potential to transform your entire manufacturing process easily.

However, the process of actually using one of these tools can be finicky. Band saws are very effective, but you need to make sure that you know what you’re doing.

This article provides all the information you need to cut with band saws, as well as a few tips you will find useful.

What Is A Band Saw Used For?

An Introduction To The Band Saw

Let’s start with the major bone of contention here – what is a band saw?

Well, like all saws, these tools are used to cut through materials. The tool works with different materials, so you’re not particularly limited here. And, with its use of metal teeth and two rotating wheels, it is able to essentially move fast along the material and make whatever cut you need it to.

Like many other power tools, band saws are very versatile. So, the look of a particular band saw will definitely not be the same as how another looks. But, the underlying structure here is for the saw to be able to cut precisely and effectively – no matter the material you put in front of it.

You can find different types of band saws available – and, we’ll check out these types in a later section. But, no matter what you’re working with, there are some basic parts of these saws that need to be in your tool. These include:

- Cutting Blades: Is there really a saw without a blade? Of course, not. Every band saw needs a primary cutting tool, and that’s what the blade offers. There are different tooth configurations available, and you can find the blades available in different band saw sizes based on what material you’re working with.

- Wheels: A band saw will come with two wheels – one at the top, and one at the bottom. Essentially, the blade is wrapped around the wheels, while they rotate to create the motion needed for continuous cutting.

- Working Table: You sure can’t cut your material in space. The table provides a proper base for you to work with, and there are even tables that allow you to tilt it if you need to cut across a specific angle.

- Guide Blocks and Bearings: These tools help to maintain alignment for the blade and the table as the cutting goes on.

- Blade Tensioner: You use the blade tensioner to adjust the amount of tension the blade has. This, in turn, helps with proper alignment.

- Blade Guides: With your hand band saw, you have blade guides that direct the blade’s orientation and position. For accuracy, these guides are critical.

As we said, there are so many fields that make use of band saws. From woodworking to metallurgy and more, the adoption of these tools is only expected to grow more.

These tools are especially prominent for their ability to cut curved and intricate shapes with optimal precision across the board. And since you can find them in different designs, you have a broad range of options to work with.

Types Of Band Saws

When choosing a band saw, one of the most important decisions you’ll make is the type you go for. Mostly, this is because there are just so many types available that choosing one can be a challenge.

Nevertheless, familiarity with the different types of band saws should help make this better. So, here are the popular types of band saws available:

Woodworking Band Saws:

The woodworking band saws are mostly used to cut wood. Their blades are wider, and their teeth are coarser. So, whether you’ve got a resawing task or would like to cut through curves and other woodworking tasks, these saws are perfect.

Just as well, these saws mostly come with longer tables and could have dust collections and other features.

Metal Cutting Band Saws:

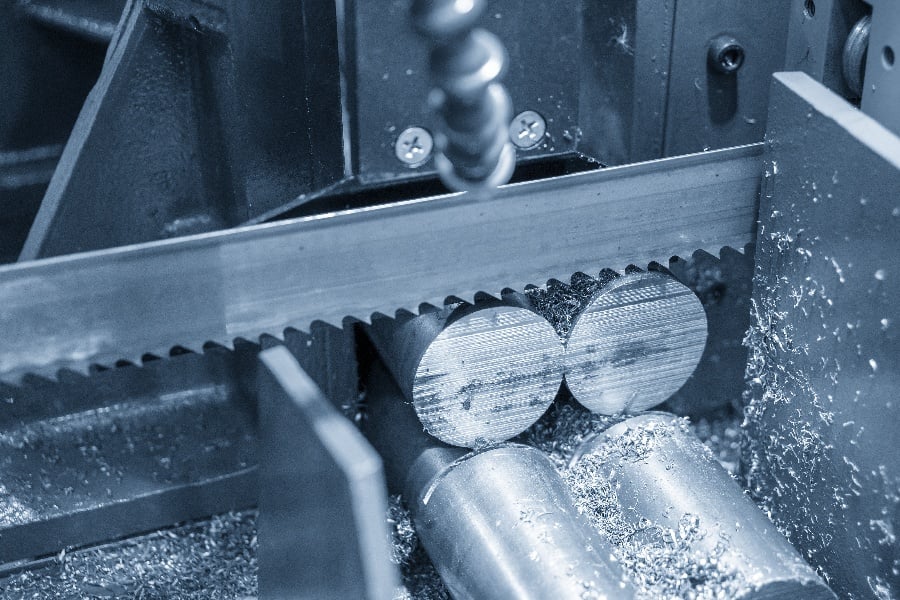

Band saw cutting metal, used to cut metal, these saws work for just about anything – aluminum, steel, and more. Their teeth are finer, and they tend to work slower so that they can maintain precision as they cut.

Metal band saw cutting machine, you can also find some models that handle vertical cutting, although most of them are horizontal and mostly ideal for cutting long metal pipes or bars.

Band Saws Oriented by Orientation.

Mostly, you have two types of band saws in terms of orientation:

Vertical band saw cutting machine are those that are equipped with straight-up mounted blades. They offer a high degree of flexibility and accommodate various cutting operations.

Conversely, you have horizontal band saw cutting crooked, which mostly excel at making straight cuts for tasks such as metalworking among others.

Portable Band Saws

Portable band saws represent a versatile tool in the field of construction. They offer convenience and precision for cutting various materials – including metal, wood, or even plastic.

Hand Band Saws

Known for their compact shapes and maneuverability, hand band saws frequently populate construction sites or plumbing tasks; they facilitate swift and precise cuts in these environments.

Benchtop Band Saws

Compact in shape, these saws have earned a lot of recognition for their versatility. They can be table-mounted or affixed to a workbench, and their prevalence extends primarily within small workshops

Band Saws for Resawing

The resaw band saw, with its wide blade and robust motor, excels in the specialized task of transforming thick wood pieces into slimmer boards.

Band saws for Meat:

This specialized band saw is employed in meat processing. It boasts blades that are tailored to effortlessly slice through substantial cuts of meat.

Contour Band Saws

A contour band saw becomes necessary for cutting through intricate materials. It is a tool predominantly employed in crafts and pattern-making. With this saw, one can effortlessly achieve detailed curves and cuts across various materials.

Band Saw Cutting: Different Types Of Cuts

Cutting Straight Lines With A Band Saw

Straight lines are quite easy to work with. Since you don’t have to make any twists, you should be ready to go. So, here are the steps to follow generally.

Choose Your Blades Correctly

First, choose the blade you’re working with carefully. At the end of the day, this will come in very handy because you don’t want a situation where you use the wrong blade for the wrong material.

Pay Close Attention To The Blade Tension

For the next step, look into the overall tension of your blade. Since blades differ, there’s no uniform way to do this. So, check out the manufacturer’s recommendations and the instruction manual.

How Will The Saw Cut?

Now, before you start cutting, check the blade’s guides and make any necessary adjustments. Remember that these guides will go a long way to ensure that your saw is stable as it cuts.

Setting Up The Table & Fence

If you have a fence, then we strongly advise that you make use of it. Ensure the fence stands at an appropriate distance from the blade to direct your straight cuts. Finally, secure the fence meticulously for optimal safety and functionality.

Set the Blade Height

Typically, the blade’s protrusion above the material should measure approximately 3mm; importantly, it must surpass the workpiece’s thickness.

Feeding of Materials

Now, you’re prepared to initiate. Turn on the band saw, then allow its blade to achieve full speed. Subsequently, without haste or force but with a deft touch, introduce your workpiece into the awaiting teeth of your saw’s blade.

Ensure a firm grip on the material. Guide the material through the cut with one hand, while using your other hand to stabilize it. Avoid exerting excessive pressure; instead, allow the blade to manage and control each incision.

Maintain a Straight Line

As you cut, you want to keep your eye fixed on the cutting line. Gently guide the material along the fence and make smooth movements to avoid going off course.

At this point, you already have a system. So, just keep feeding the material into the saw until you’re done with the cut. After that, turn the saw off.

Now, it’s important here for you to let the blades stop spinning before you hold the saw after you turn it off. The last thing you want is an injury of some sort.

Important: Always Look Out for Yourself

This is a saw. And, if you’re not careful, the risk of injury can be high. So, take precautions to protect yourself.

First off, stand at a reasonable distance from the saw and its blades as you operate it. And, make sure you have your safety goggles and earmuffs. Saws give off a lot of noise, so you want to protect your ears just as much as you protect your eyes.

Once you can ascertain that the cut is smooth, you’re good to go. If not, then you might need to add some sandpaper to the cut to smoothen it out.

Making Curved Cuts With A Band Saw

If you think that making straight cuts with a band saw is challenging, then curved cuts will completely redefine that even more. Because curved cuts tend to be intricate, it’s even more important to be careful with these ones.

A band saw machine will need to be properly calibrated to do this, and you might even need to get a template to make sure you don’t go about cutting the wrong way.

To that end, here are the steps you’d need to follow to get things done:

Choose the Right Blade

As always, you want to choose the right blade. Whether you need small band saws or larger ones, figure out your requirements.

Also, remember that smaller teeth tend to work for tighter curves, while larger teeth are ideal for gentler, delicate curves.

Mark the Curve

With a marker or a pencil, draw the curve you’re trying to make onto the workpiece. If you’re working with a template, then you can just trace it onto the material to ensure seamlessness.

Blade Entry Point

Choose a specific point on the curve where you’ll begin cutting. This point should be able to accommodate the blade and begin the process.

Start The Saw & Feed The Material

You’re ready to go. Turn the band saw on and let the blade get to full speed, then position the workpiece so the blade can enter at your designated entry point, where the material will be fed into the blade.

Maintain Control

Guide the material with both of your hands and focus on making smooth and controlled movements as you glide around the curve. Keep your eye on the mark as well so you know you’re ensuring accuracy across the board.

Once the cut is completed, turn the band saw and wait for the blade to stop. Then, remove the workpiece.

Keep Yourself Safe

As always, maintain a safe distance from the blade and watch your hands. Put on the right safety gear, and follow the manufacturer’s instructions for proper safety.

Remember the place of quality control, and see to it that every part of the final product is fresh and ready to go. If the need arises, sand through the product to take out any roughness.

How To Set Up A Band Saw

So you’ve got your band saw ready and would like to start with the cutting process. But, are you sure the band saw is properly set up?

If you’re not, then you might want to spend some time going over some of these tips:

Always Read The Manual

Manufacturers give you manuals for a reason, and you should check them out. Get familiar with their instructions and make sure to follow them. From assembly to making adjustments and more, go through these materials exhaustively.

This is especially true since there are different types of band saws with different requirements. So, the last thing you want is to use a specific band saw type inappropriately.

Keep An Eye On Blade Tension

We already explained the importance of blade tension. So, your job here is to make sure that the tensioning is done based on the manufacturer’s instructions. If this factor isn’t properly optimized, you could end up with some inaccurate cuts and find that the blade starts to wear even earlier than expected.

Choosing & Installing The Blade

Once again, remember to spend enough time going over the different blade types and choosing the one that works for your material. Once you do, check the manufacturer’s manual and install it based on their instructions.

The blade should sit well, and tracking on the wheels should be appropriate.

Blade Guides and Bearings

Your blade guides and bearings should be placed based on the manufacturer’s instructions too. This way, the blade stays on the determined path and you can ensure that your cuts are as accurate as possible.

Blades On Wheels At All Times

This is very important. The blades of the saw should always sit on the wheels, and make sure to adjust the tracking if the need arises. You sure don’t want a situation where the blade comes off as the saw is working.

Align The Fence

You can adjust the fence of the saw to make sure you get accuracy in cutting. The fence should be square to the table, and ensure that you keep a tight fit so it doesn’t move.

Run Tests And Adjust When You Can

Before using the saw on your material, we recommend that you test it with waste materials first. This way, you’re sure of its accuracy. And if you need to make any adjustments, you can do so without compromising your material.

Most times, you’d find that optimal performance doesn’t just happen at the first go.

Don’t Forget Maintenance

Band saw cutting machine, Like every other machine, your band saw will only be as good as you are to it. And with proper maintenance, you can make sure that you get the most out of this material at every turn.

So, before you start using it, create a schedule that describes your maintenance requirements and responsibilities. Basic things like cleanliness and lubrication should be accounted for, and you also need to check for any possible wear and tear.

If you want the saw to work for as long as possible, these are the things you need to prioritize.

Always Stay Safe

You’re working with a band saw – a material that is inherently dangerous. So, please remember to stay safe and be careful when near it. Wear protective clothing, and make sure that you don’t go near the saw when its blades are spinning. At the end of the day, safety comes first always.

Advantages & Disadvantages Of Band Saw Cutting

Band saw cutting has proven to be an incredibly useful process with impressive results. And as you would imagine, the process is used across different industries for its efficiency. That said, you also have a few bottlenecks to contend with.

Let’s take a quick look at where the band saw projects shine and where they might need some work:

Band Saw Cutting: Advantages

- Used Wherever: Band saws cut different materials. You can use them to cut straight and curved surfaces as well, so there’s no one-size-fits-all approach. Whatever you need to cut, there’s a high chance that a band saw uses no stress to get it done.

- Quick Precision: If you follow the tips we sent you on setting up your band saw, you’ll find that you’ll be able to make sharp and precise cuts at all times. When you need to conduct a detailed task, these saws are perfect for you.

- Sharp Cutting: You’d also find that band saws usually work faster than most other cutting requirements. Even when you’re cutting intricate and irregular shapes, the saws work quickly.

- Zero Waste: You get minimal waste materials from band saws. This is mostly because their blades are thin, so they don’t create much debris.

- Saw Once And Again: Band saws allow the process of resawing – where you cut a board multiple times to achieve the piece you’re looking for. As long as you have what you want to achieve in mind, band saws can help make that happen.

- Smooth Cutting Action: These days, cuts need to be clean – not just accurate. And with band saws, you can combine both benefits. As expected, you need to make sure that you have the saw properly set up to enjoy this.

- Easy On The Pocket: Generally, band saws tend to be more cost-effective when it comes to cutting than most other cutting procedures. And since they cut different materials, you shouldn’t have much to worry about.

Possible Challenges With Band Saw Cutting:

- The Long Setup Process: Probably the biggest challenge you’d find with a 14 bandsaw is that setting it up can be a bit of a challenge. You need to spend time to get everything put together, and you need a lot of expertise too. That said, if things are done right, you get to enjoy a lot of benefits.

- Not Suitable For All Thickness: Band saws tend to be limited when it comes to the thickness of materials they can handle. However, you can work around this thanks to resawing.

- Excess Noise and Vibration: While they work, you’ll notice that band saws generate a lot of noise. This is why we recommend that you wear earplugs to guard your ears.

- Possible Weaknesses In The Blade: We already pointed out that the blades on a band saw are thin. Because of this, there’s a propensity for them to wear quickly or even break. And if they’re cutting thicker or harder materials, this propensity is significantly increased.

- The Need For Safety: Once again, remember to approach band saws carefully and have your safety gear on. Follow the manufacturer’s instructions on using the saws correctly, and make sure that your setup process is done right.

Tips for Sawing Efficiency

To close things out, we thought it would be appropriate to share a few tips that can help you ensure that your saw is used properly and efficiently. As you set up the saw and make use of it, keep some of the following tricks in mind:

Work Through The Setup

Before you begin using the band saw, ensure that you assemble it right and adjust it based on what the manufacturer said in their manual. All factors should be accounted for, and you need to ensure that every aspect of the saw is operating optimally.

Use The Correct Blade:

Band saw cutting blade, We can’t stress this enough. Before you start cutting, ensure that you have the right blade for the material you’re working with. If you need a 10 in bandsaw and you get a 12 inch band saw instead, you probably won’t get the results you’d like.

Consistency In Rates

One major area where you want to ensure consistency is with the feed rate. Essentially, you want to make sure that you’re feeding the material into the saw. But, you also want to make sure that you’re not adding too much pressure on the saw.

Simply allow the blade to cut naturally instead of shoving the material through it. This way, you maintain cutting efficiency and achieve a sleeker finish.

Speed Should Be Just Right

Depending on the material you’re cutting, work with the right speed. We recommend that the speed should be higher when you’re cutting soft materials, but you can choose a bespoke speed that works for you.

If the blade works too fast or too slowly, there’s a chance that you might not find the right outcome at the end of the cutting process.

Care For The Machine

Before every cutting process, apply lubricant to the blade to ensure that heat and friction are reduced. Just as well, you can use cooling methods to help get the most out of your blade.

Define Your Cuts Beforehand

Before you cut, make sure you have a pattern ready for the blade to follow. These marks will guide the blade and ensure that it doesn’t veer off your

Achieving Optimal Operation

There’s a chance that you’d need to accommodate things like tool changes and material handling as the saw operates. Plan for those to ensure that you don’t end up spending an awful lot of time during the process itself.

Just as well, organize your workspace to reduce interruptions as much as possible and streamline the saw’s operations for metal fabrication.

Set Time To Practice

Trust is, you won’t get the band saw cutting process at once. This is why you want to practice as much as possible. Practice cutting both straight and curved paths, and ensure that you grow your skills over time.

Conclusion

Band saw cutting has become a viable manufacturing process across the board, thanks to its flexibility and versatility. And as long as you have the setup right, you should have no problems whatsoever with the process.

Want to learn more? Reach out to us at KDM Fabrication and we’d be more than happy to help you out!