In the metal fabrication industry, brushed metal finishing has become very popular. Have you ever seen a shiny piece of modern art sculpture, a car, or an electric device and wondered, “How did they get such an amazing finish on that metalwork?”

Well, that’s the remarkable work of brushed metal finishing.

The brushing finish has been applied to a wide range of household items. We use it in applications such as high-end appliances and automotive parts.

This finish is important because it makes a metal surface look better. Additionally, you can apply it to enhance a product’s durability and functionality.

What is A Brushed Metal Finish?

A brushed metal finish creates fine, homogeneous patterns on uneven metal surfaces. You’ll end up achieving a unique matte aesthetic on the surface.

To achieve this finish, you need a brush or a belt sander alongside a fine (80-120 grit), greaseless abrasive — for smoothening.

A brushed finish can hide minor flaws by smoothening and deburring metal edges for fabrication. That is a consistent, noticeable texture with an eye-catching look. The brushed metal finish is relatively scratch-resistant compared to a smooth, polished surface.

This finish style is commonly applied to aluminum, stainless steel, and nickel materials. It is essential to keep the metal in good shape for a long time.

Beware that a brushed finish can be easily damaged. This technique reduces the corrosion resistance of a metal’s surface. Here’s why. The texture achieved limits the surface’s ability to hold liquid droplets. Over time, this could lead to rust particles forming on the object.

However, the PROS of brushed finishing outweigh its disadvantages. We recommend this finish for decorative applications, precision machining, and fabrication.

There are three different styles/techniques for brushed finishing.

Types of Brushed Metal Finishing Options

When selecting an ideal brushed finish option for a metal surface, choose a style that suits your desired surface texture and aesthetics.

During fabrication, we should consider the intended purpose of the end product.

You might want a stylistic effect or something that serves an industrial purpose. Check out the different styles and patterns of brushed finishing:

Linear Brushed Finish

This finish is commonly applied to kitchen appliances. To get a linear finish, brush the metal surface constantly in a straight, consistent direction.

A linear finish is perfect if you want to achieve a refined, uniform, parallel-line appearance. This finish is a simple D-I-Y option that you can achieve yourself.

Circular Brushed Finish

As the name suggests, this finish delivers a homogeneous set of circles on a metal’s surface. This circular design is accomplished by rotating an abrasive brush on the surface in a circular motion.

Most wristwatch manufacturers often apply this finish style globally to create a classy, noticeable design

Cross Brushed Finish

Cross-brushed finishing is a technique that involves brushing a metal surface bi-directionally. Or, should I say, in two different directions!

Unlike other brushing techniques, this finish generates a crossed/intersecting pattern, thus achieving impressive depth and contrast that is easily noticeable. It’s an excellent choice for a brushed finish for achieving a little criss-cross style on a surface.

How to Achieve a Brushed Metal Finish – Step-by-Step

- Pre-brushing Stage

- Brushing Stage

- Post-brushing Stage

STEP 1: Pre-brushing

This is the first stage of the brushed finishing process. During this stage, you should clean the material to get rid of dirt, oil, rust, or any scratches on the surface.

Apply a grease remover like alcohol, then scrub the surface with sandpaper or a wire brush. Before you begin the process, put on safety gear, such as goggles, gloves, and a dust mask.

These tools are essential to protect you from harmful debris and chemicals. After cleaning the material, you can proceed to the next step, ‘the brushing stage.’

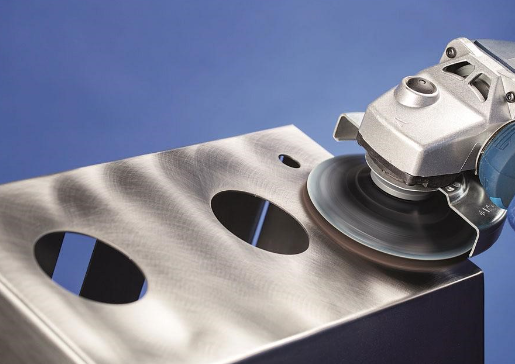

STEP 2: Brushing Stage

Before you begin the brushing process, ensure you have the appropriate brush for the desired finish. You can use an abrasive wheel or steel wire brush during this task.

Also, you should choose an appropriate brushing technique if you want to achieve a specific pattern on the surface.

Begin brushing the metal surface consistently in the brushing direction of your choice to achieve homogeneous brush strokes. Hold the brushing tool at a slightly tilted angle while applying even pressure in every direction.

Remember, you should keep the brushing speed and pressure consistent to accomplish an even texture on the finish.

We recommend regular inspections during the brushing process to monitor your progress and ensure you achieve unique aesthetics on the surface. You should adjust your brushing technique if necessary.

STEP 3: Post-brushing

This is the final step for getting a brushed finish. After brushing your metal, thoroughly clean the surface using soap and water. During post-brushing, you can use clean clothing or compressed air to dry the metal surface.

Make sure you rinse and dry the surface finish to get rid of any dirt particles or metal residues produced when brushing.

You can traditionally clean the surface finish or use a rinsing water tank if you can access one in your workspace. At our metal fabrication factory, the rinsing tanks contain chemicals, polishes, and surfactants. These components serve the post-brushing process seamlessly.

As soon as the metal surface is dry, you can utilize metal wax to add a coating layer. This will protect your brushed finish from wearing out quickly.

Don’t forget to perform a final inspection to ensure you’ve achieved the desired style with the brushed finish.

What Material Can Be Brushed?

- Stainless Steel Brushed Finish

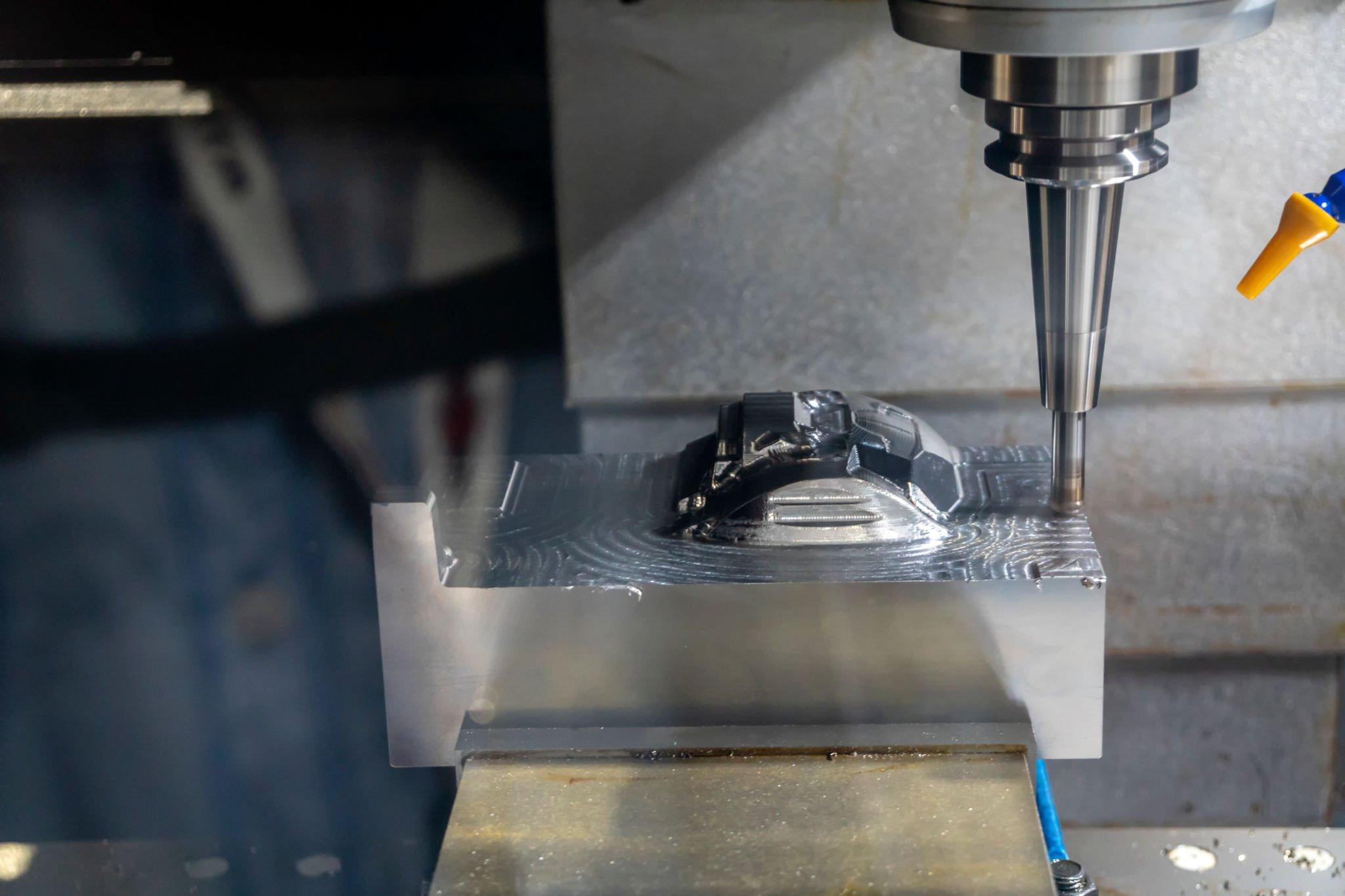

Since stainless steel is corrosion-resistant and durable compared to other materials, it is popularly used in the CNC fabrication industry to achieve a brushed surface finish.

We utilize stainless steel brushed finishes to design kitchenware, household appliances, and architectural products.

We use steel-bristle brushes to achieve a brushed finish on steel surfaces. However, you can also use fiber brushes or metallic wire wool to get a brushed finish on stainless steel parts.

Aluminum Brushed Finish

Due to its corrosion-resistant and lightweight aesthetic nature, aluminum is adaptable to brushing finishes in the metal fabrication industry. A brushed finish gives a smooth, sandblasted look to an item’s surface.

We usually apply a brushed finish to aluminum when manufacturing furniture, decorative household items, and automotive parts.

Nickel Brushed Finish

Brushing nickel will give you a dull, silver-gray surface finish. We apply the brushed nickel finish to manufacture decorative accessories such as kitchen cabinets, door handles, and faucets.

Brass Brushed Metal Finish

Brushed metal gold, or brass is suitable for brush finishing. During fabrication, you can brush the golden-yellowish brass surface to generate a matte, satin-like finish.

While brushing reduces the reflection properties of brass, it enhances the elegant appearance of the metal surface. We use brushed brass in the manufacturing of musical instruments and decorative accessories.

Comparing Brushed Metal Finish to Other Types of Finishes

A brushed finish is one of the several popular finishing techniques that we use in our CNC fabrication and precision machining factories. Let’s see how a brushed finish relates to other metal finishing techniques.

What is the difference between a Brushed and Mirrored Finish?

Mirrored finishing involves extensive polishing to achieve a glossy and highly reflective finish on a metal surface, thus replicating the surface of a mirror. Alternatively, a brushed finish enhances a matte appearance, thus minimizing reflections.

While brushed metal finishing delivers a scratch-resistant surface as the end product, a mirrored finish creates a refined surface with a polished texture. A mirrored finish is usually vulnerable to scratches and fingerprints.

This finish demands more attention and care to maintain its spotless look. Its reflective nature makes a mirrored finish suitable for household accessories and jewelry.

What is the difference between a Brushed and Bead Blasted Finish?

To achieve a bead-blasted finish, one blasts glass, tiny abrasive beads, or ceramic non-directionally against a metal surface (sand-blasting). This finishing technique generates a frosted, grainy appearance.

On the other hand, brushed finishing involves brushing abrasive pads or a wire brush in a specific direction to achieve an elegant, semi-matte texture. Brushed finishes are commonly used to manufacture steel products, kitchen accessories, and high-end architectural products.

The bead-blasted finish is commonly applied to surfaces that don’t need a directional texture. Its applications include firearm parts, automotive surfaces, decorative sculptures, and industrial machinery.

What is the difference between a Brushed and Satin Finish?

Most people confuse satin with brushed finishes. A satin finish has a smoother, slightly glossy (shiny) look, unlike a brushed finish with a matte appearance.

Due to its directional texture, brushed finishing suits industrial applications like deburring and edge-blending architectural appliances.

Satin finishes are relatively rust-resistant compared to brushed finishes. Therefore, a satin metal finish suits kitchenware applications and other products used in humid surroundings.

What is the difference between a polished and brushed metal finish?

Unlike the feature textured, matte-looking brushed finish, a polished finish achieves a smoother, non-directional, and reflective surface. We consider a shiny finish when seeking a high-gloss luxurious look for a product.

In contrast to brushed finishes, polished finishes require consistent maintenance measures since they are prone to scratches. Polished finishing is favorable for ornate fixtures, jewelry, and high-end automobiles.

Applications of Brushed Metal Finishing in CNC Fabrication

- Deburring

Deburring involves brushing a metal surface to remove unwanted burrs and uneven or rough metal edges. It’s also effective for protecting metal surfaces from destructive rusting and corrosion. We should use metal finishing brushes or exclusive CNC brushes built for the deburring process.

- Edge blending

This process involves brushing the edges of a metal part to create a smooth and uniform texture for smooth transitions between two surfaces. During precision machining, this method can produce distinct, sharp edges.

It’s a suitable application for assembling industries seeking to integrate various parts to achieve a unified product.

- Cleaning

KBM Fab utilizes abrasive brushes to clean metal surfaces in the global CNC fabrication industry. You can use brushed finishing to eliminate stains, rust, dust, film, weld slag, and other contaminants.

It’s efficient at scrubbing unwanted defects from metal surfaces. Brushing a surface is an effective technique to restore the distinct appearance of a product.

- Roughening

Lastly, you can brush a metal surface to achieve a rough texture, thus increasing paint adhesion. This reduces the chances of the paint coatings peeling or wearing out, even under harsh weather conditions.

Moreover, roughening a metal surface before painting makes cleaning easier and enhances durability.

Related Application of Brushed Metal

- Brushed metal jewelry

- Brushed metal vinyl wrap

- Brushed metal sockets

- Brushed metal wrap

- Brushed metal bump map

- Brushed metal door handles

- Brushed metal paint

- Blender brushed metal

Tips and Best Practices to Achieve Brushed Metal Finishing

How to get brushed metal finish?

- Using the proper technique: Consider adhering to the respective brushing technique tailored for achieving the desired pattern and radial brushed metal texture on the surface.

- Using the right tools: Before brushing a surface, assemble the appropriate tools suitable for achieving a particular finish on the material.

- Cleaning the Surface: You should clean the metal surface using fine-grit sandpaper for best results. This will create an even and smooth texture on the metal surface.

Pros and Cons of Metal Brushing Finishes

Advantages of Brushed Metal Finishes

- It enhances aesthetic features and boosts durability.

- It makes the surface smooth and comfortable.

- It improves the paint adhesion of a metal surface.

- It makes surfaces easier to clean.

- It increases rust and corrosion resistance.

Disadvantages of Brushed Metal Finishes

- Brushed finishing limits the surface’s ability to hold liquid droplets.

- It makes a surface prone to damage.

- Under high pressure, it can cause surface defects.

- Achieving a high-quality finish might be complex since it demands skilled labor and CNC equipment.

- The brushed finish has a matte look, thus limiting reflectiveness for several applications.

Brushed Metal Finishing – Conclusion

To achieve a perfect brushed finish on a metal surface, machined parts require the best finish with proper machining. Besides achieving an appealing aesthetic, the finish makes the brushed metal part more durable.

Therefore, selecting the appropriate finish technique is crucial for excellent results. We recommend consulting professional metal fabrication technicians at KDM Fab – Brushed metal sheet, the best sheet metal fabrication factory in China.

At KDMFAB, we are committed to handling all your metalwork needs. Contact us today for more information regarding our CNC and metal fabrication services.

Frequently Asked Questions

What factors do I consider when selecting brushing equipment for a metal surface?

Here are five key factors to consider when selecting the ideal brushing equipment:

- The material and surface type

- Application (Purpose)

- Type of Brush Bristle Material

- Size and Texture of the Brush

- The Speed and Brushing Power

How do you get a brushed metal finish?

- Step 1: To get a brushed metal finish on a metal surface like stainless steel or aluminum, you must first decide the direction of the grain pattern.

- Step 2: Depending on the desired effect, you should use wire brushes, sandpaper, or abrasive pads to make regular linear or circular strokes in the grain pattern.

- Step 3: Maintain adequate pressure and consistent strokes for a uniform finish.

- Step 4: Clean the surface and apply a clear coat or protective finish for ultimate durability and appearance.

Which type of brush is the best to use for brushed metal finishing?

Steel wire brushes are often used in metal manufacturing to give the metal a brushed finish. They are prominent because they can clean surfaces without tearing off the base material or changing the dimensions of the metal surface. Basically, these brushes clean surfaces just like sandblasting does.

How do you make shiny metal look matte?

The first step in achieving a matte finish on metal objects is cleaning and sanding. Start by thoroughly degreasing the workpiece using soap and water. After that, utilize fine-grit sandpaper within the range of 220 to 400 to refine any surface defects.