About Aluminum Tags

They can hold consecutive numbering, logos, graphics, barcodes and QR codes. These tags can be customized according to your specific requirements through marking, stamping, embossing, and engraving techniques. If you have any specific demands for artwork, photography, or logos, we offer you printing services utilizing either silkscreen or digital technology.

Aluminum tags serve the purpose of labeling or identifying products with variable information. Typically, the thickness of our aluminum tags ranges between .005 and .250 and comes in various shapes including round, square, and rectangular. To meet your various color requirements, we have gold, copper, red, blue, and green shades in stock.

Additionally, our aluminum tags are simple to affix to equipment, inventory, and other surfaces.

Types of Aluminum Tags

Features of Aluminum Tags

Aluminum tags are chosen for various applications due to their specific features and properties. Here are some common features of aluminum tags:

- Durability: Resistant to corrosion for long-lasting use.

- Lightweight: Ideal for applications where weight matters.

- Customization: Easily personalized with text, numbers, logos, etc.

- Fade Resistance: Maintains legibility over time, even in sunlight.

- High Contrast: Offers a surface for clear and easy-to-read markings.

- Chemical and Heat Resistance: Can withstand exposure to various conditions.

- Versatility: Suitable for diverse applications like labeling, identification, and tracking.

- Cost-Effective: Often an economical choice.

- Recyclability: Environmentally friendly due to high recyclability.

Applications of Aluminum Tags

Aluminum tags have a wide range of applications across various industries due to their durability, versatility, and customizable nature. Here are some specific applications:

- Industrial Equipment Identification: Aluminum tags are used to label and identify machinery and equipment in industrial settings, aiding in maintenance and operational procedures.

- Asset Management: Businesses use aluminum tags to track and manage assets, making inventory control more efficient.

- Pet Identification: Aluminum tags serve as durable and customizable pet tags, displaying important information such as the pet’s name and owner’s contact details.

- Luggage Identification: Aluminum tags are employed as durable luggage tags for easy recognition during travel.

- Name Badges: In professional settings or events, aluminum tags may be used as name badges for employees or attendees.

- Product Labeling: Aluminum tags are used in manufacturing to label products with essential information like serial numbers, manufacturing dates, and safety instructions.

- Horticulture and Plant Identification: Aluminum tags are utilized in gardening and horticulture to label plants and trees, providing information about species and care instructions.

- Warning Signs and Safety Labels: Aluminum tags are employed to create durable warning signs and safety labels in industrial, construction, or hazardous environments.

- Electrical Panel Marking: Aluminum tags are used to label circuits, switches, and components in electrical panels for clear identification.

- Medical ID Bracelets: Aluminum tags are sometimes used in medical bracelets to display critical health information for emergency situations.

- Promotional Products: Customized aluminum tags are used for promotional purposes, displaying logos or messages as branded giveaways.

These applications highlight the adaptability of aluminum tags in providing durable and reliable identification across diverse industries and contexts.

The Process of Making Aluminum Tags

The process of making aluminum tags can involve several steps, depending on the desired characteristics and customization. Here is a general overview of the typical process:

- Material Selection:

– Choose a suitable grade of aluminum based on the application requirements (e.g., 3003, 5052).

- Cutting:

– Aluminum sheets are cut into the desired tag shapes and sizes using cutting tools such as shears or laser cutting machines.

- Surface Treatment:

– Clean the aluminum surfaces to remove any impurities.

– Optionally, treat the surface for improved adhesion of coatings or printing.

- Printing or Marking:

– Apply information, logos, or serial numbers to the tags using various methods:

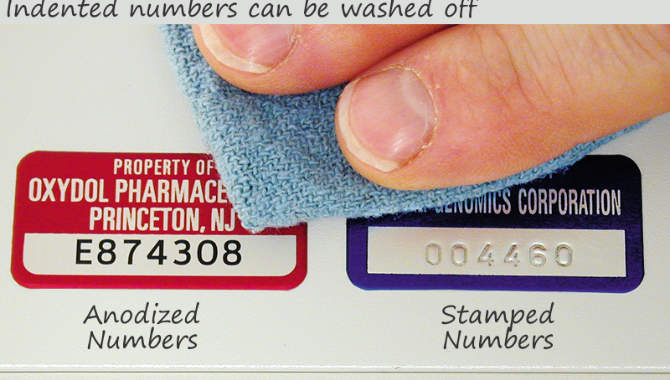

– Engraving: Removing material to create indented markings.

– Embossing: Creating raised markings on the surface.

– Printing: Applying ink or a coating with the desired information.

- Hole Punching or Drilling:

– Create holes in the tags for attachment, such as using a hole punch or drilling machine.

- Anodizing (Optional):

– Anodizing is a process that can enhance the corrosion resistance and appearance of aluminum. It involves immersing the tags in an electrolytic solution and applying an electric current.

- Coating (Optional):

– Apply protective coatings for additional durability or to enhance visual appeal.

- Baking or Curing (if applicable):

– If coatings or prints require curing, the tags may be subjected to heat for a specific duration.

- Quality Control:

– Inspect tags for accuracy, quality, and adherence to specifications.

- Packaging:

– Package the finished aluminum tags for distribution or further use.