MIM stands for metal injection molding, a manufacturing method that combines injection molding and powder metallurgy. A thermoplastic binder and fine metal powders are mixed, the resultant material is shaped into intricate forms, and it is then sintered and debonded. This produces complicated metal components with excellent mechanical qualities that are very precise and ideal for small and intricate pieces.

Method of Metal Injection Molding

Compounding: The preparation of feedstock, also known as compounding, is the first step in the MIM process.

Molding: Injection molding uses the same tools and methods as plastic injection molding.

Debinding: Following injection molding, the molded component advances to the subsequent stage known as the binder removal procedure, also known as debinding.

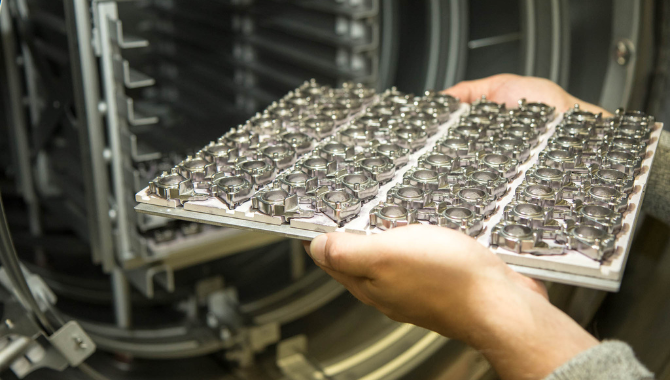

Sintering: The debind components are arranged on ceramic setters and loaded into a furnace that is heated to a high temperature and has an atmospheric control system.

Finishing: Metal injection molding does not involve finishing or grinding operations. A few finishing or machining processes may be carried out on the sintered item, depending on the final requirements.

Process of Molding: A few finishing/machining operations may be carried out on the sintered item, depending on the final requirements.

Utilizing Metal Injection Molding

Because of all the benefits that metal injection molding provides, it is widely utilized in a wide range of industries, including agriculture, the medical field, and even everyday consumer goods.

MIM is utilized in the medical sector to create precise medical equipment like:

- Surgical tools

- Implants for orthopedics

- Replacement of the hips

- Dental implants and crowns

Metal injection molding produced parts are seen in agriculture for items like pruning shears and tractor parts

Metallic Injection Molding: Advantages and Disadvantages

Advantages

Complex Geometric Forms

Metal injection molding components can be used to create components that are both aesthetically beautiful and functional.

The economy of scale

Metal injection molding is seen as cost-effective due to several factors, including less labor and waste.

Constant Excellence

The following variables affect metal injection molding’s ability to provide consistently high-quality results:

- Replicability

- Constant Raw Material Quality

- Environment Under Control

Density together with Strength

Metal injection molding parts can be produced with exceptional mechanical qualities, such as strength and hardness, thanks to their high density.

Disadvantages

Starting Out Costs

A debinding oven, a sintering furnace, and an injection molding machine are a few examples of the specialized equipment needed to fabricate metal.

Lead Time for Production

It may take weeks or months to construct a new mold and produce components with a new design, particularly for sophisticated goods.

The price of changing a design

One must make a special mold to form the part by each design. If a new mold needs to be manufactured due to a requirement for a design modification, lead times and price will increase.

Most Often Used Materials for Injection Molding Metal

- Fe-Ni (alloy 42, Invar, and so forth)

- F15: often known as Kovar

- Fe-Si: Up to 9% silicon concentration

- Fe-Co superior magnetization.

One of the more widely used metal production techniques nowadays is the metal injection molding method. Examine this: between 1986 and 2004, the MIM market experienced significant growth, rising from USD 9 million to over USD 380 million. The process’s effectiveness and affordability are two of the main factors contributing to its popularity. For best metal injection molding companies choose KDMFAB.

- Iron

- Nickel

- Chrome

- Molybdenum

Although metal injection molding is a flexible process, its constraints concerning mold size may make it unsuitable for large, bulky objects.

Because of the setup and tooling requirements associated with metal injection molding, it is often more appropriate for mass production than prototyping.

The production of Metal Injection Molded parts is subject to industry-specific quality standards. Manufacturers often comply with industry-relevant standards like ISO 9001 and others to ensure the consistent production of superb components.

Technologies are being developed to provide multi-material capabilities, however, MIM has historically used a single material for each part.

It’s important to take into account the environmental impact of components used in metal injection molding, such as binders and powders, even if the process can be rather efficient. Request metal injection molding pdf for more information.

For injection molds, copper is the best material for work.

For producing precision items, titanium metal injection molding is frequently a more efficient method.

- MIM – can produce small parts with complex features.

- Die casting – is better suited to larger parts.