Custom Sheet Metal Pallets Fabrication

The sheet metal pallet is a heavy-duty structure that allows moving products swiftly from one location to another. It makes heavy loads easy to store and hassle-free to handle. This has become increasingly significant in production, automotive, logistics, and transportation.

KDM offers a vast array of sheet metal pallets to meet every industry demand. Available in various sizes, dimensions, materials, colors, entry types, and load capacity. We have galvanized steel pallets, aluminum pallets, and iron steel pallets, to name a few. Heavy-duty, rust-proof, high load-barring power, and tensile strength are some of its distinct advantages.

Moreover, we can custom sheet metal pallets based on your business preference. Can configure all details mentioned above. Please feel free to send us your design.

An eco-friendly single-side sheet metal pallet is suitable outdoors. Ideal for palletized racking and high-level racking. The weight of the load varies from 300 to 2000 kilograms. Available in white, blue, orange, green, or as your requirement.

The 4-way metal pallet is heavy-duty and non-reversible. It’s ideal for palletized racking and high-level racking. Maximizes space utilization and ease of operation. Logos and numberings are available upon request.

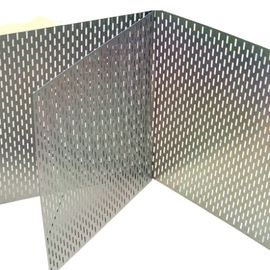

KDM metal pallets with press-formed sheets are made of sturdy, durable sheet metal and will last a long time. It provides fire protection ideal in the automotive, metallurgical, and industrial sectors. Can be customized with or without a lip for bundling.

The sheet metal pallet with a two-way entry is suggested for heavy-duty racking systems. It is compatible with all types of material handling equipment. Hallmarks include sturdiness, incredible durability, and dimensional precision.

The sheet metal pallet with a one-ton capacity is an excellent tool for storing and transporting bulky, delicate items. It has a high load-bearing capacity, a long life, and is corrosion-resistant. Can customize colors.

KDM offers flat storage steel pallet featuring a solid, close-boarded, or slatted top deck. Also available with a raised lip to prevent product slipping. These durable steel flat storage pallets come in various sizes and are made to order.

Sheet Metal Pallets By Sizes

Sheet Metal Pallet By Material

Sheet Metal Pallets Advantages

Sheet metal pallets are strong and long-lasting. Also, they last longer than wood or plastic pallets. They are stiffened by the steel composition, which allows them to survive adverse weather conditions.

The metal pallets are easy to clean and ideal for use in all cleanrooms. They may be cleaned without difficulty since it’s made of finely finished steel. The best method for cleaning them is pressure washing.

Pallets made of metal exist in various shapes, sizes, and sorts. The elegance of pallets lies in how they are built to form a structure capable of aiding the movement of products. Available in vast design.

Because the metal pallets do not burn, they are entirely fireproof. Aside from that, they are durable enough to resist the rigors of extreme conditions. They are resistant to mild and low temperatures.

Why Choose KDM Sheet Metal Pallets

KDM series of sheet metal pallets have several distinct advantages. We provide high-quality, heavy-duty metal pallets in various sizes and dimensions to match your individual needs. It is also available in a diversity of designs. They are more durable in severe settings.

KDM sheet metal pallets are:

- Simple to use and require little maintenance

- Resistant to chemical pollutants and corrosion

- Do not break under large loads

- Able to carry heavy dynamic and static loads

More attributes contribute to metal pallet popularity. Any industry you belong to, this is your perfect material handling solution.

Choose KDM to Custom Your Sheet Metal Pallet

KDM has been engaged in sheet metal pallet production for more than ten years. We tend to offer high-performance metal pallets throughout years of expertise and knowledge. Our team also make custom steel pallet to suit various environments and applications. Please share your needs with us, and we will find the ideal solution for you.

Our expert engineers can design your custom sheet metal pallet in just 1-2 days. All required features were applied to the product. In compliance with ISO9001, PPAP, and CPK standards, we can assure quality output.

Whether you have a small or large-scale business, KDM sheet metal pallet is your #1 choice. All products were tested before delivery. A complete test report is available. Get strong load carriers for your industry demand and take full benefit.

KDM Sheet Metal Pallet Fabrication

KDM applies numerous forms of surface treatment to our sheet metal pallet. The available finishes include:

- Galvanizing

- Wet Painting

- Untreated

- Hot Dipping

- Powder Coating, and so on.

- Low Maintenance

- Easily Cleanable

- Robust Construction

- Ergonomic Handling

- Strong Load Capacity

- Rust-proof

- Durability

- Bacteria-resistant

- Recyclable and Repairable

OEM & ODM KDM Sheet Metal Pallet Applications

The sheet metal pallet for logistics and transportation provides high loading and unloading efficiency. It also offers flexible handling and reduces the time spent waiting for transportation tools.

KDM offers heavy-duty warehouse sheet metal pallets for shipping metals, liquids, and other products requiring weight support. It enhances operating efficiency.

Metal pallets make item handling and heavy load transfer a snap in the construction industry by stacking heavy items on top of them. Features high load-bearing capacity, corrosion resistance, sturdy design, and durability.

The metal pallet can withstand harsh weather conditions. It is specially built to resist chemicals and dangerous materials. They enable you to transport chemicals efficiently.

Sheet metal pallets are ideal for the automotive sector because of their distinctive features. It includes high stacking loads, durability, and long-term dry storage. Corrosion-resistant and rust-free.