Springs are mechanical devices of high significance used to affect motion, enhance shock-absorbing capacities, etc., in a number of products. They are being used in all kinds of machines ranging from trucks to watches. However, they are not in the same size, design, shape, and materials, following the specific needs of the respective machine or device.

Therefore, to understand what kind of spring is required for any purpose, it is vital to be aware of the major types of springs, their mechanism, and usage. In this regard, we are exploring some key types of springs in this article.

The Basics of Springs

Before digging deep into the types of springs, it is vital to understand the basics of springs. A spring is a tool or device that stores and releases energy when a force is applied to and removed from it respectively. Under normal circumstances, regardless of the type of spring or product it is used in, it will return to its normal shape upon the removal of load.

The use of springs in any product is based totally on Hooke’s Law. Hooke’s regulation truly demonstrates the relationship between the “force” exerted on a spring and its elasticity. In easy words, Hooke’s laws express that the pressure wanted for spring compression and extension is directly proportional to the displacement.

Mathematically, Hooke’s Law is described as F= -kX,

F = pressure applied to the spring

X = displacement of the spring (the averse value implies that the restoring pressure is opposite to the direction of force.

K = is the spring consistent. It relies on the nature of the springs and indicates their stiffness.

Major types of Springs

Following are some of the major types of springs that are used in a comprehensive range of products and machines;

Mechanical Springs

Coil Springs

A coil spring is a helical-fashioned mechanical tool that is close-wound or open-wound. Coil springs keep mechanical potential power. They can be made from elastic and metallic substances, including hardened steel. You can find coiled springs in a large number of everyday gadgets, from farm machines to toys, trampolines, and plenty more.

A coil spring works by storing power on the way to launch it, absorb surprise, or hold pressure among surfaces. If you apply excessive pressure, you may stretch a spring beyond its restriction, which allows you to permanently distort the spring.

The coil springs come in many designs and shapes. The very first steel coil spring was made in 1857 for an armchair. Today, you can find coil springs in countless normal merchandise, such as:

- Automobiles

- Door handles

- Clocks

- Toasters

- Retractable pens

- Gates

- Toys

- Garage doorways

Leaf Springs

Leaf springs are springs product of square metal plates, additionally called leaves. The square metallic plates are usually bolted and clamped and are especially utilized in heavy vehicles. Below are a few types of leaf springs and their usages:

- Single leaf spring: This is the handiest kind of leaf spring, and it is used in light motors.

- Multi-leaf spring: This kind of leaf spring has more than one leaf, and it’s used in heavy automobiles.

- Semi-elliptical leaf spring: This type of leaf spring is curved and utilized in vehicles and buses.

- Elliptical leaf spring: This kind of leaf spring is more curved than the semi-elliptical leaf spring, and it is utilized in heavy trucks.

- Paraboloidal leaf spring: This type of leaf spring is the maximum curved form of leaf spring, and it’s miles utilized in heavy vans and trailers.

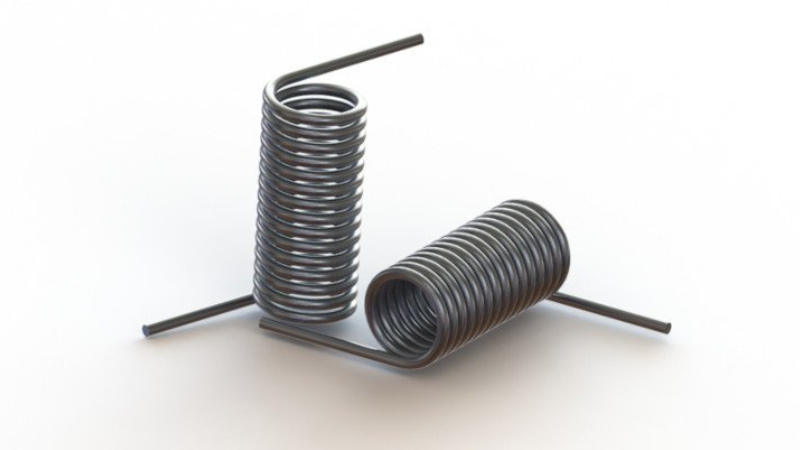

Torsion Springs

Torsion springs are coils or strips that can be helical or flat spiral in shape. They are used to both follow or withstand torque loads. The key specs to take into account when deciding on torsion springs are the spring fee, wire diameter, material, spring end type, and torque score at a deemed function. These springs are typically used in manufacturing applications as components for various motion controls.

There are two basic kinds of torsion springs: helical torsion springs, which can be much like compression or extension springs and act radially to apply torque, and spiral torsion springs, which can be wound as concentric spirals generally from flat or rectangular inventory. Torsion springs are available in a lot of different styles and sizes, ranging from watches and clocks to motion controls in automatic machinery. They may be custom wound or purchased in stock sizes or collection kits.

Gas Springs

Gas springs are mechanical cylinders and rods that use nitrogen or other inert gases to create pressure and force on a piston or rod To determine the best fit for a particular application, consider key terms such as stroke, compressed and expanded length, strength, and features

Gas springs are commonly used in the automotive industry to raise and lower hoods or hatches and come in various sizes and shock lengths to handle different weight requirements. They can also be found on office chairs for seat height adjustment.

Fluid Springs

Fluid springs, also known as hydraulic springs, employ beverages to keep and transmit mechanical electricity, serving as options for standard mechanical springs. They capitalize on the incompressibility of fluids to uniformly distribute forces. Fluid springs offer blessings like adjustable stiffness, precise force management, and damping capabilities. They locate packages across industries such as automobile, aerospace, and robotics. These springs typically encompass a fluid-stuffed cylinder with a shifting piston or diaphragm, complemented by way of valves for stress and go with the flow law.

Various kinds of fluid springs exist. Hydraulic accumulators are fundamental and utilized in hydraulic systems for strength garage and shock absorption. Hydropneumatic springs integrate liquid and gasoline for adjustable springing and damping and are common in car suspensions. Electrorheological (ER) and Magnetorheological (MR) fluid springs utilize unique fluids touchy to electric or magnetic fields for speedy pressure manipulation. Pneumatic springs rely on compressed air for springing and damping consequences. Boussinesq-Plateau fluid springs are specialized for biomechanics and clinical simulations. Electrohydrostatic actuators rent electric power for precise pressure and movement control in heavy equipment. The preference for fluid spring relies upon specific software necessities.

Composite Springs

Composite springs are mechanical components composed of different substances, including metals and composites, to keep and launch mechanical strength. They excel in various applications because of their specific properties. Examples consist of material-reinforced composite springs for automobile suspensions, composite leaf springs in heavy-duty cars, and composite Belleville springs for commercial use. Sporting systems and biomechanical implants also make use of composite materials for stability, stiffness, and flexibility.

The benefits of composite springs include weight reduction, corrosion resistance, customization, and outstanding vibration damping. They are especially precious in weight-sensitive industries like car and aerospace. However, there are drawbacks, including better prices, complex manufacturing procedures, fabric compatibility demanding situations, and limited temperature tolerance. Despite these limitations, composite springs offer revolutionary solutions to meet specific engineering needs and are being used in an extensive range of applications where their benefits outweigh the hazards.

Unique and Specialized Springs

Springs find particular usages across niche industries, along with medical gadgets, aerospace, and automotive sectors. In the clinical field, miniature springs are essential for insulin pumps and pacemakers, while stent springs assist in holding open blood vessels. Aerospace is based on touchdown tools springs and valve springs for secure landings and engine overall performance. Automotive makes use of suspension springs for cushy rides and seatbelt retractors for protection.

Unusual spring designs serve specialized purposes. Constant force springs provide constant pressure in gadgets like retractable pens, wave springs are healthy in tight spaces, torsion springs offer twisting pressure, and vortex springs generate fluid vortices for fluid dynamics research. These examples spotlight springs’ versatility, adapting to precise needs in numerous industries, from ensuring human well-being to enhancing system performance and contributing to scientific studies. Springs are a quintessential detail in engineering, bringing balance, safety, and precision to an array of numerous and sudden programs.

Factors Influencing Spring Selection

For best performance and lifespan, selecting the proper spring requires taking into account a number of parameters. Load requirements, including size and direction, as well as deflection requirements and spring rate, are critical. Material selection is influenced by environmental factors as well as fatigue life requirements.

Operating temperatures must be kept within material limitations, and space is limited. The frequency of operation influences fatigue life, and environmental circumstances influence material selection. Cost factors may restrict possibilities, but safety concerns may mandate redundancy or safety precautions.

Different types of springs qualities are required for static and dynamic loads, and mounting arrangements must be appropriate for the application. Specific damping qualities are required for vibration or shock absorption springs. Corrosion resistance is critical in corrosive situations, and standard and regulatory compliance is frequently required.

Conclusion

Springs are versatile mechanical gadgets that can be used in a wide range of applications. They may be crafted from plenty of materials, consisting of steel, plastic, and composite substances. Springs are to be had in quite a few shapes and sizes, and they may be designed to satisfy the particular desires of the application. When selecting a spring, it’s essential to take into account the burden requirements, deflection necessities, spring rate, material, operating temperature, frequency of operation, value, safety, and mounting preparations.