The history of milling machines dates back to the early 19th century, initially for producing weapons, machinery, and metal parts. With the Industrial Revolution, they became crucial in manufacturing.

This article covers milling machines’ background, types, uses, maintenance, and selecting the right one, providing comprehensive purchasing guidance for you.

what are milling machines

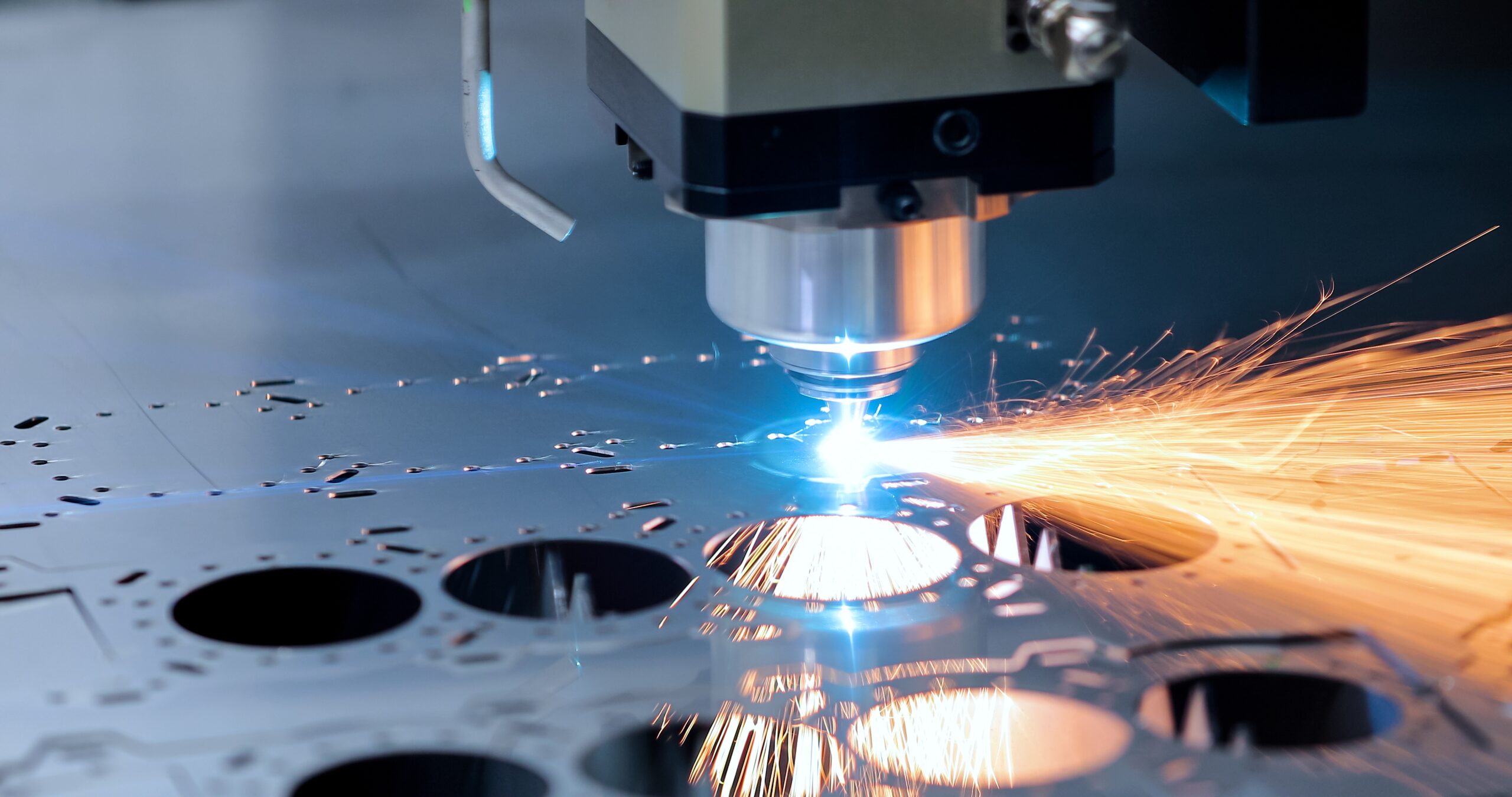

A milling machine is a machine tool used to process workpieces, and you can remove excess material from the workpiece by operating rotating cutting tools. You can commonly use milling machines for processing metals, but you can also use them for processing other sturdy materials, such as plastics or wood. You will find milling machines widely used in your daily life, and you can utilize them to produce various parts and products, from large mechanical parts to precision crafts.

Importance of milling machines in various industries

Milling machine is a machine tool that processes workpieces by milling, drilling, and boring, which can greatly concentrate the processes, shorten the production cycle of company products, improve the production efficiency of your company, and your company will gain greater economic benefits.

Advantages and disadvantages of milling machines

Understanding the advantages and disadvantages of milling machines can help you better comprehend and evaluate their applicability and limitations.

Advantages

- Versatile Functionality:Milling machines are capable of performing various operations, including plane milling, slot milling, contour milling, and gear milling, among others. They can be applied across various fields.

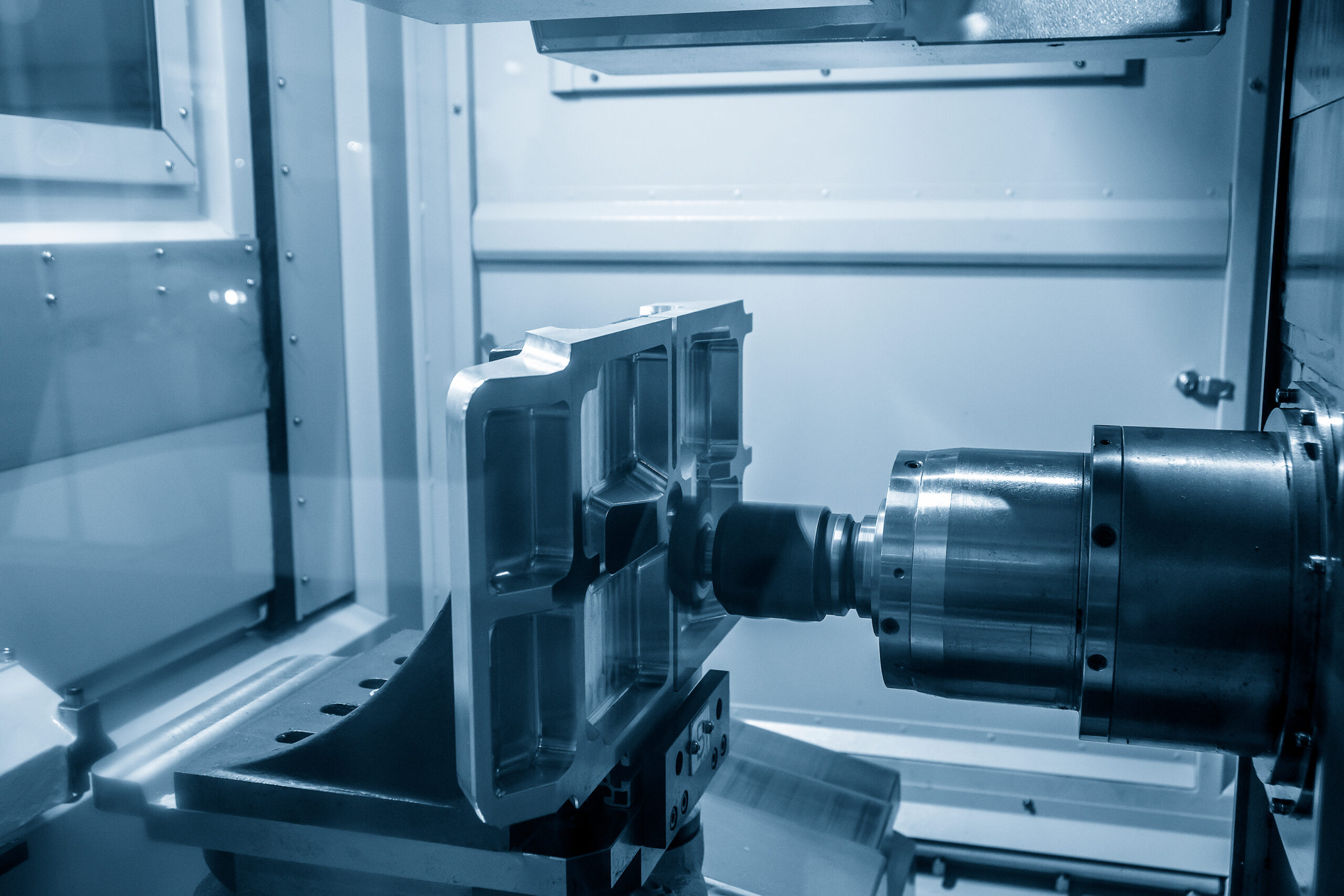

- High Precision:With the development of technology, milling machines are constantly being updated and improved. Today’s milling machines are capable of processing workpieces with increasing precision, achieving extremely fine tolerances. The advent of CNC milling machines, in particular, has been able to meet the majority of machining requirements.

- Processing Complex Parts:Multi-axis CNC milling machines in particular can simultaneously control three or more moving axes, allowing the cutting tool to work on the workpiece from different angles. This capability enables the machining of complex contoured workpieces and reduces the need for multiple setups, providing significant advantages when processing many complex parts.

- Increased Efficiency:CNC milling machines can be programmed to automate the milling process, reducing the uncontrollable factors associated with manual labor and improving production efficiency.

Disadvantages

- High Cost:The purchasing and maintenance costs of high-end CNC milling machines are very high, posing a significant financial burden on companies.

- Complex Operation:Operating professional milling machines, especially CNC ones, requires specialized knowledge and skills for programming and operation. This necessitates either the recruitment of experienced operators at a higher cost or significant time investment in training.

- Equipment Maintenance:Milling machines require regular maintenance, including lubrication and the replacement of worn-out cutting tools, incurring additional costs to maintain precision and functionality.

- Environmental Impact:Milling machines occupy a large floor area and often generate significant noise during operation, which can disrupt other work processes. Additionally, the cutting process produces debris, requiring companies to allocate additional workspace to accommodate milling machine operations.

Components of Milling Machines

Here are some of the basics of what makes up a milling machine,The components of a milling machine are roughly composed of 9 components, divided into the following parts:

- Base: supports the entire machine tool, with a certain level of hardness and strength

- Bed: the main body of the machine tool, on which most of the machine tool is installed

- Crossbeam: with attached brackets, the crossbeam can move along the top guide rail of the bed

- Spindle: a hollow shaft with a tapered hole at the front end, transmitting power to the spindle

- Spindle speed change mechanism: changes the fixed speed of the main motor through gear to drive the spindle

- Vertical worktable: used for mounting workpieces and driving the workpiece to move vertically

- Horizontal worktable: located between the vertical worktable and the lifting platform, used to drive the vertical worktable to move horizontally

- Lifting platform: located on the front side of the bed on a vertical guide rail, driving the worktable to move up and down along the vertical guide rail

- Feed speed change mechanism: changes the fixed speed of the feed motor through gears to achieve various speeds for the movement of the worktable, in order to meet the needs of milling.

A comprehensive and detailed understanding of these components can give you a thorough understanding of the structure of the milling machine, and hopefully help you operate the milling machine more efficiently.

Types of milling machines

there are many types of milling machines commonly used in manufacturing and metal processing. Each type has its specific advantages and uses. Understanding these different types of milling machines can help you work more efficiently, leading to higher economic benefits. Here are a few common types:

Benchtop Milling Machine

The machine is supported by a benchtop and is mainly used for milling small parts such as instruments and meters. It is commonly seen in home workshops, repair departments, or small-scale production settings. Because of its ease of operation and relatively small size, benchtop milling machines are often used for processing precision parts or for repair work. Benchtop milling machines include:

Horizontal Bench Milling Machine: A benchtop milling machine with a horizontally arranged spindle.

Vertical Bench Milling Machine:A benchtop milling machine with a vertically arranged spindle.

Cantilever Milling Machine

This is a type of milling machine where the head is mounted on a cantilever. The bed is arranged horizontally, and the cantilever can typically move vertically along the column guide on one side of the bed. The milling head can move along the cantilever guide and has a large processing range, making it suitable for processing large castings, molds, fan blades, and other large parts. Cantilever milling machines include:

Cantilever Milling Machine: A cantilever milling machine equipped with a milling head.

Cantilever Boring and Milling Machine: A cantilever milling machine equipped with a boring and milling head, capable of boring operations.

Tooling for milling machines

The milling machine tool is an important part of the machining process, as it determines the efficiency and accuracy of milling operations. This means that choosing the right milling machine tool is crucial. Milling machines typically use several types of cutting tools, each with specific purposes:

- Milling Cutters: Milling cutters come in various types, with the most common being the upright milling cutter. These cutters are used to remove material from the workpiece. They come in different shapes and sizes, such as square end mills, ball end mills, and corner radius end mills, each suitable for different applications.

- Face Milling Cutters:Face milling cutters have a larger cutting diameter and are used for facing and milling larger flat surfaces. They typically use indexable carbide inserts for cutting.

- Shell End Mills: Shell end mills are larger milling cutters with multiple inserts used for heavy-duty milling operations, including slotting, side milling, and face milling.

- Milling Inserts: These are the cutting tools installed on the milling cutter. They come in various shapes and materials, such as carbide, metal ceramic, and ceramic, to meet different processing requirements.

- Tool Holders and End Mill Holders: These are used to secure end mills and other cutting tools to the spindle of the milling machine, providing stability and precision during the cutting process.

- Tool Holder: The tool holder is used to secure cutting tools to the spindle and allows for quick and precise tool changes.

Materials for Milling machines

As a powerful milling tool, so what are some of the common materials that you know can be used as milling?

- iron: Often used for the machine’s base, bed, and various structural components due to its excellent vibration damping properties and stability.

- Steel: Commonly used for the machine’s cutting tools, workholding devices, and other components due to its durability and machinability.

- Aluminum: Used for lighter components such as covers, guards, and some structural parts due to its lightweight and corrosion resistance.

- Brass and bronze: Occasionally used for bushings, bearings, and fittings due to their low friction properties and resistance to corrosion.

- Plastics: Utilized for non-structural components, covers, and electrical insulation due to their low weight, ease of machining, and electrical insulating properties.

By understanding the materials required for milling and refining the entire set of production processes, it can be better applied to the manufacturing industry and other fields.

The application of milling machines

You can use a milling machine as a type of machine tool to process metals, plastics, wood, and other materials. It is one of the most common equipment in mechanical processing, widely used in manufacturing, aerospace, automobile manufacturing, electronics, medical equipment, and other fields. Its main applications include:

Automotive Industry

Milling machines are primarily used to manufacture engine cylinder heads, crankshafts, and other precision parts. They ensure the stability and longevity of vehicles through precise milling, while also enhancing driver comfort.

Aerospace Industry

In the aerospace industry, milling machines are mainly used to produce aircraft structural components such as wings and fuselage parts, as well as to process engine components like turbine blades and casings. As aerospace technology advances, the increased precision required for aircraft poses a significant challenge for milling machines.

Mold Manufacturing

In practical applications, milling machines are mainly used in the development and processing of molds. They can quickly produce molds according to design requirements through precise operations and reasonable processing paths. Additionally, milling machines can control the surface finish and processing quality of molds through different cutting methods and processing parameters.

Mechanical Manufacturing

Milling machines are primarily used to process various mechanical parts such as gears, bearings, and transmission devices. In the automation industry, milling machines are crucial for producing machined parts based on mechanical drawings and for manufacturing irregular connecting components in non-standard designs.

Medical Equipment

Milling machines are mainly used in the manufacturing of surgical instruments, orthopedic implants, customized prostheses, and supports. This demands extremely stringent accuracy in processing, ensuring patient safety.

Education and Research

Schools and research institutions use milling machines for teaching and experimental projects. These milling machines are relatively old and lack high precision, mainly serving to facilitate student internships.

Basic Operation of a Milling Machines

Milling machines have a wide range of applications in the mechanical processing industry. The above has introduced some concepts and types of milling machines, but rich theory also needs practical support. Are you eager to know how milling machines are operated?

- Part Planning: First, you need to have a plan for processing the workpiece. It’s best to have the engineering drawings needed for processing prepared in advance. The drawings should indicate dimensions, tolerance fits, and geometric tolerances. This way, the processed workpiece will be more precise.

- Workpiece Preparation: Prepare the materials needed for processing. The material must be larger than the finished workpiece, and it’s best if the material is square-shaped for easier clamping.

- Clamping the Workpiece: Clamp the workpiece onto the workbench, ensuring that all degrees of freedom are securely fixed to prevent movement and rotation during processing. Otherwise, it could result in material wastage at best and pose a safety threat at worst.

- Setting Parameters: Based on the requirements of the workpiece and the processing goals, set appropriate cutting parameters, including cutting speed, feed rate, and cutting depth. These settings will directly affect the processing results and the surface quality of the workpiece.

- Start Processing: Once everything is ready, start the milling machine and begin processing. The cutting tool rotates and moves along a designated path, cutting the workpiece surface and gradually shaping it into the desired form.

- Processing Inspection and Adjustment: Throughout the processing, continuous checks on the quality of the processing are needed, and adjustments should be made as necessary. This includes inspecting the dimensional accuracy, surface finish, and flatness of the workpiece.

- Processing Completion and Cleanup: After the workpiece is processed, the milling machine surface needs to be cleaned. Remove chips and residual cooling lubricants to extend the milling machine’s lifespan.

Selecting the Right Milling Machines

When choosing a milling machine, how can you select one that is suitable and can save money and effort? You can consider the following factors:

- Processing Requirements: First, consider the type, size, and material of the workpiece that needs to be processed, and determine the required processing capabilities and precision.

- Functional Features:Different milling machines have different functional features. For example, CNC milling machines can achieve automated processing, while integrated milling machines are suitable for small-scale processing. Choose the appropriate functional features based on specific requirements.

- Processing Precision: For workpieces with high precision requirements, it is necessary to select milling machine equipment that can provide high-precision processing.

- Process Requirements: Consider the requirements of processing technology and procedures, such as whether high-speed cutting, multi-axis linkage, and other special processing capabilities are needed.

- Maintenance and Care: Consider the maintenance and care of the equipment. Select equipment that is easy to maintain and repair to ensure stable operation.

- Quality and Brand: Choose well-known brands and reliable quality milling machine equipment to ensure performance and reliability.

- Cost Considerations: Take into account the equipment’s purchase cost, operating cost, and maintenance cost, and choose equipment that fits the budget.

Maintenance and Care of Milling Machines

After understanding some basic knowledge and operation of milling machines, I believe you may still have some concerns. For example, how long is the lifespan of a milling machine? How should it be maintained in the later period to extend its lifespan and accuracy?

Regular Inspection of the Milling Machine’s Lubrication System

The normal operation of the milling machine’s lubrication system is crucial for maintaining the precision and stability of the machine tool. It is best to perform this check once a month. Check the quality and remaining amount of the lubricating oil, and replace it in a timely manner. When replacing the lubricating oil, remember to use oil that is compatible with the machine tool.

Maintaining the Cleanliness of the Milling Machine Surface

Impurities on the surface of the milling machine can affect its machining accuracy and easily lead to damage to tools and workpieces. Clean the milling machine surface regularly, both before and after use. You can use specialized cleaning agents and soft brushes to clean off impurities and dust. At the same time, be careful not to use hard objects to scrape the milling machine’s surface to avoid causing scratches.

Pay Attention to the Working Environment of the Milling Machine

The milling machine should be placed in a dry, well-ventilated environment, avoiding direct sunlight and damp areas, and preventing dust from entering the interior of the machine tool. Try to avoid storing other miscellaneous items near the milling machine to avoid affecting the normal operation and maintenance of the machine tool.

Regular Maintenance and Overhaul of the Milling Machine

It’s best to do this once a year. Regularly inspect the degree of wear of various parts of the milling machine, such as guide rails, spindles, and fixtures, and perform repairs or replacements as needed. Also, conduct various accuracy tests, such as parallelism and perpendicularity, adjust and record the test results to maintain the machining accuracy of the milling machine.

CNC Software Updates and Data Backup

It’s best to do this every three months to keep the CNC in optimal working condition.

The Future trends of milling machines

In the manufacturing industry, milling machines play a vital role. With the continuous advancement of technology, milling machines are also evolving. The future of milling machines will be more intelligent, automated, and will focus more on green manufacturing and processing new materials, which will bring greater growth and change to your company!

conclusion

The professional capabilities of milling machines are extremely powerful. Although they currently have some limitations, with thorough understanding and proper use of these machines, you can reap significant benefits. If you are interested in learning more about milling machine prices and detailed specifications, please contact kdmfab. We look forward to hearing from you!