This article describes the optimal techniques for producing high-quality laser engraving on titanium. Titanium can only be engraved with the appropriate tools, despite being a useful metal for many uses.

Remarkably durable and glossy, titanium is a lightweight material that doesn’t tarnish or corrode. Its strength-to-density ratio is also the highest of all the metallic elements. Titanium is becoming a more common metal for use in a wide range of product manufacturing applications because of its amazing qualities.

Types of Lasers Engravers Machines for Titanium

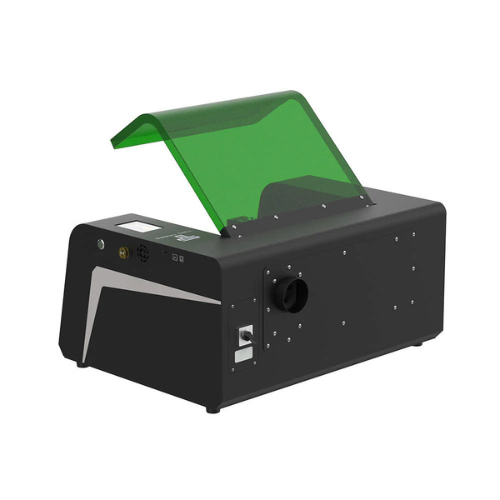

Vanadate laser engraver devices offer superior beam quality, peak powers, and depth of focus.

In cold marking applications, these green laser systems offer greater beam stability, power, and speed.

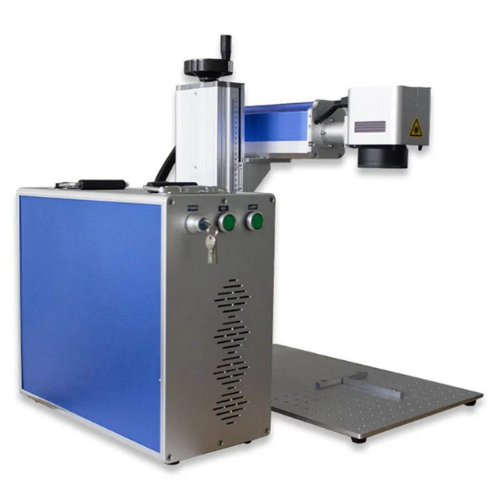

Titanium is easily engraved with a fiber laser marker. These devices require no consumables and are accurate, flexible, and multifunctional.

When a specific spray is applied beforehand, CO2 laser marking solutions can be used to engrave bare minerals such as titanium.

Cold marking applications can benefit from the use of ultraviolet laser engraving, which produces finely detailed micro-markings.

Dual-head laser systems allow you to process titanium quickly by using a single controller to operate two laser markers simultaneously.

How Does Titanium Laser Engraving Work?

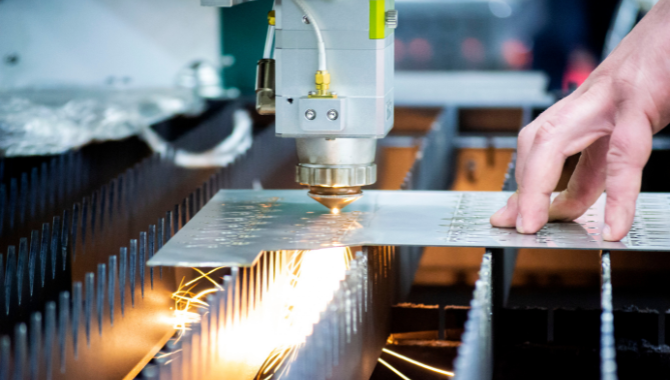

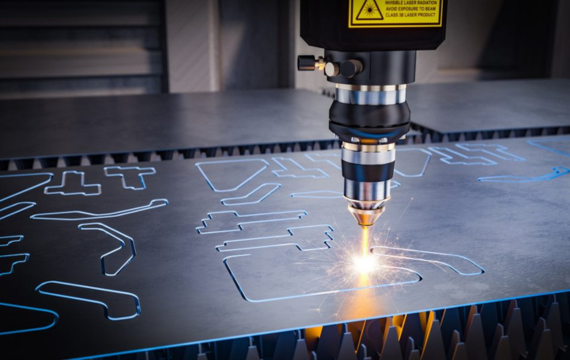

A powerful laser beam is used to precisely and carefully heat the titanium surface.

This procedure, which does not require extra inks or chemicals, produces a mark that is observable and lasting by changing the physical properties of titanium.

The Benefits of Titanium Laser Engraving

Resilience

- Titanium provides exceptionally robust and legible engravings due to its exceptional resistance to abrasion and deterioration.

Ability to Resist Corrosion

- Titanium has a broad range of applications due to its high corrosion resistance.

Precision and Defining Features

- Titanium is a material that is frequently used in high-tech, aerospace, and medical industries where accuracy is critical, and it is particularly favorable in these conditions.

Procedure Without Contact

- By using a non-contact laser engraving technique, the titanium surface is shielded from direct contact with the engraving tool.

Adaptability

- Customizing titanium products for usage in a range of sectors is feasible thanks to the versatility of laser engraving.

Extended-Term Marking

- Titanium has readable, long-lasting laser engravings.

Efficiency and Swiftness

- It can be used for both large- and small-scale production.

Unresponsive and Stated Process

- The process of laser engraving is contactless. Consequently, the engraving process is orderly and environmentally safe.

Extraordinary Finish Quality

- Following laser engraving, titanium has a polished, flawless finish.

Appropriate Applications for Titanium Laser Engraving

Medical equipment serial numbers, lot codes, and other identifying information can be marked.

Aircraft parts can be marked with part numbers, serial numbers, or other important information.

Titanium rings, bracelets, and other items can have elaborate and customized patterns and inscriptions.

Easy tool tracking, branding, and identification are made possible by laser engraving, which also improves inventory control.

High-end consumer devices like watches, laptops, and cell phones employ titanium. To give the items a premium and unique touch.

Serial numbers, logos, and other identifying information are frequently engraved with a laser on gun parts and accessories.

Laser engraving can be used for branding, personalization, or logo addition. Similar to camping equipment, golf clubs, or bicycle frames.

In professional or industrial contexts, engraving names, trademarks, or other information on titanium tools or equipment can improve personalization.

Using laser engraving, designers can imprint complex patterns, designs, or images for aesthetic purposes on titanium surfaces.

Titanium can be laser engraved for aesthetic, branding, or product traceability reasons.

- 2D barcodes

- data matrix codes

- QR codes

- serial numbers

- VINs

- Logos

- And more can all be examples of this.

Given its remarkable versatility and precision across a wide range of surfaces, a fiber laser is the perfect tool for laser engraving or branding titanium.

Depending on the size, number, and complexity of the engravings, titanium laser engraving might have varying costs.

The accuracy and durability of the marks make it a cost-effective option for many applications over time, even though there may be setup fees initially.

In terms of medical uses, titanium laser engraving is safe.

The inscriptions are robust, biocompatible, and immune to sterilization techniques frequently employed in the medical industry. The procedure is non-invasive.