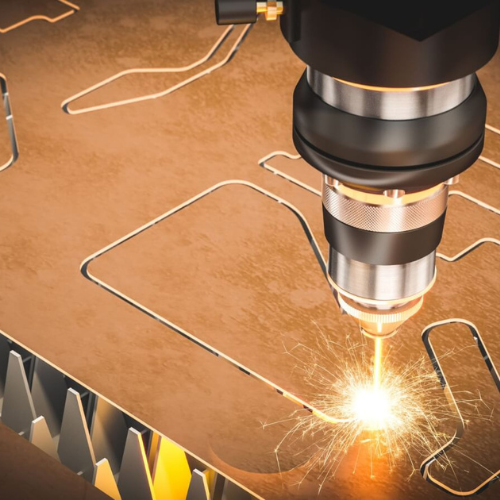

Brass Laser Cutting is an efficient, reliable, economical, method for making intricate parts and products. This is known as one of the fastest cutting processes that ensures great cutting without any damage to materials. With that, it guarantees to provide great finish parts for a wide variety of applications in different industries. If you are looking for futuristic innovation, laser cutting is one of them. Keep Reading!

Wide Range of Techniques Using Laser Cutting

Laser engraving on metal is the process is drawn, creating lettering, and images on the top layers of material in a fast and easy way. It happens by simply removing the top layers and changing them into any design as needed. These are commonly used for making trophies, nameplates, dates, times, brands, locations, and many more. Aside from that it is also perfect for making etch barcodes into different products.

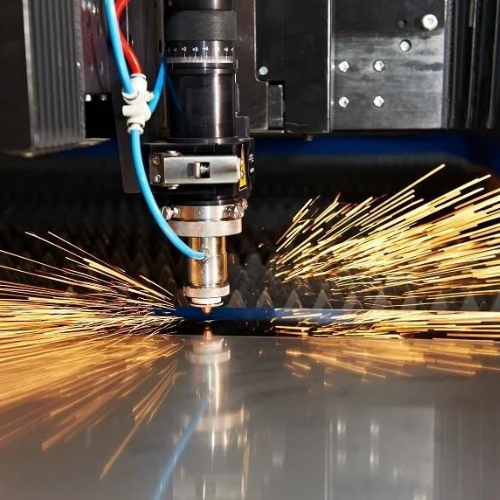

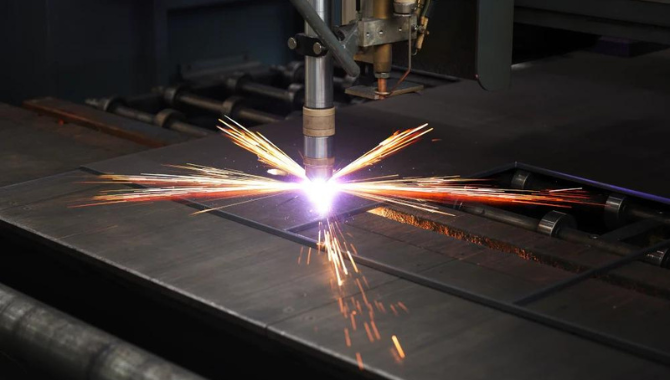

Sheet metal laser cutting is the cutting process that uses a laser beam to cut materials easily. It is perfectly designed to cut materials and make them into complex and intricate parts. Compared to manual cutting, this is highly advisable to use for making a large amount of parts in just a small amount of time.

This is quite the same with laser engraving but in engraving, it can create quality images, letters, words, and others while laser marking is only used to remove the upper parts of a material and then create a marking.

Laser Drilling also uses a laser beam but its purpose is to cut a hole into a material or cut into its surface. Meaning that the purpose of these is to drill in the material from one side to another.

Great Advantages of Brass Laser Cutting

- High Precision Cut. Brass laser cutting precisely cuts any materials and produces complex and intricate parts with the help of a narrow cutting slit. Even the brass is highly reflective through the help of a laser with a low wavelength it helps to cut more precisely.

- Broad Applicability. The laser cutting process can cut thick brass sheets and thin brass sheets. But mostly laser cutters are perfectly focused on cutting thinner components or brass sheets.

- High Speed. A laser cutter can cut brass material quickly without wasting time. This means that the process using a laser cutter is much faster compared to other methods.

- Clean Cut. Laser cutting can produce not only quality cuts but also provide a smooth edge and clean finish.

- Laser cutting is a flexible manufacturing process. It can cut any type of metal and other plastic materials.

- Cost-Effective. Even though laser cutting is expensive compared to other method of cutting. The process i highly cost-effective because it can work at high speed and cannot waste a lot of brass materials.

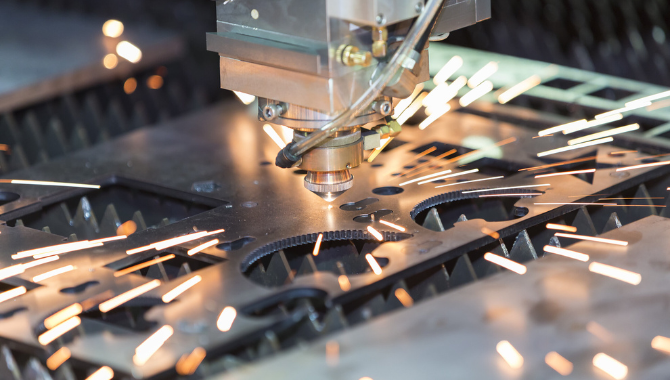

Different Parts That Brass Laser Cutting Makes

Laser brass cutting is used to make beautiful brass parts such as the following:

- Locks

- Bearing

- Gears

- Zippers

- Nameplates

- Plumbing

- Valves

- Electrical Sockets

- Electrical Plugs

- Hose Couplings

- Ammunition casing

- Hinges and more.

Consideration When Choosing Brass Laser Cutting Machines

- Laser Power – It’s highly necessary to consider what type of machine should be used with enough laser power to handle the thickness of brass materials.

- Cutting Speed – For volume production, the cutting speed is highly needed especially if a large amount of brass is wanted to be cut in just a single time. Choosing the right laser-cutting machine with high-speed features is the number one that needs to be looked for.

- Cost and Budget – When choosing the right brass laser cutting always consider its price but make sure that it offers great features and capabilities to work fast for a long period.

- Precision Cutting – Another important consideration is to look at a laser cutter machine that has high repeatability and accuracy. Aside from that make sure that it is equipped with advanced cutting technology to cut brass in precise, consistent, and great results.

- Brass Material Sizes – Another way to choose a laser cutter is to look first at the size of the brass materials that you need to cut. After that check if the laser cutter machine with a bed size can accommodate.

- Services and Support – Choosing the right machine and a reliable supplier is highly needed to achieve long-term success. That is why look for a supplier that offers technical support and quality services.

Brass Laser Cutting for Different Industry

In the decoration industry brass is a common material used to make decorative products because of its durability and appearance. With the help of brass laser cutting, it can create a wide variety of lighting fixtures, decorative screens, lampshades, etc.

Brass laser cutting machine is a popular technology that plays a big role in making home appliances such as safety valves, adaptors, water heater valves, and many more.

The laser cutting machine is perfect for making brass jewelry as one of the unique materials due to its colors and affordable price. The purpose of a laser cutting machine is to make patterns, intricate designs, and beautiful cuts which perfect for creating custom brass jewelry.

Brass laser cutting is in high demand to make products, Logos, company names, images, letters, and other promotional and advertising items.

For the metal fabrication industry, brass is the one material used to make brass heat sinks, brass gaskets, and other brass metal parts. With the help of a brass laser cutting machine, all metal parts are made in a fast and easy way.

Except from brass laser cutters can also be able to cut materials such as:

- Carbon steel

- Stainless steel

- Mild steel

- Aluminum

- Alloy

- Titanium

- Brass

- Silver

- Gold

- Bronze

- Galvanized Steel

Two common laser sources used to cut brass are the CO2 lasers, and the fiber lasers. But the fiber lasers are the most commonly used to cut brass because brass has a high reflectivity that CO2 lasers cannot handle.

- Power Setting – The important key element is to set the power in a high setting depending on how much the inches of the brass sheet are. The purpose of high-power is to reduce the consumed time spent during the cutting process.

- Speed of cutting – To get a great result the cutting must be at a lower speed at approximately 10 to 15%. The purpose of this is to prevent risk when the cut is distinguished.

- Point of focus – In cutting and creating a hole in brass materials, it is highly necessary to set the position at the top of the materials. This helps to reduce materials that interact during the process and the time that is consumed for melting the materials.

- Cutting Gas – Cutting gas is highly needed to enhance the proces reliability. Meaning that it is also necessary to use gas or high-pressure oxygen within 100 up to 300 psi depending on the thickness of the brass