What is Chrome Plating?

Chromium plating is the process of covering metal components with a thin layer of chromium. The electroplating process creates a perfect metal coating on the target object. It extends the life of metal components by reducing wear and tear. An object’s ability to withstand corrosion, reduce friction, avoid galling, and, in some cases, improve attractiveness.

Brief History of Chrome Plating

In 1797, the element chromium was found, and in 1798 it was isolated. German scientist Dr. Geuther developed the first documented chromium electrodeposit in 1855.

Emile Placet and Joseph Bonnet of Paris, France, received the first U.S. patent for chromium plating in 1894. 526114 is the patent number.

Significance and Wide Applications

- Chrome is widely used in most areas where high temperatures and corrosive elements are present.

- 80% of chromium trioxide produced worldwide is used for plating.

- Chrome plating is used in these types of industries, such as aerospace, military, agriculture, and engineering.

The Two Typical Process of Chrome Plating

Hexavalent Chromium

Hexavalent chromium plating is a standard method of chrome plating that is used in the majority of practical applications. This type of chromium is the most dangerous because it is known to cause disease in humans.

Trivalent Chromium

The primary component of trivalent chromium plating is sulfuric acid or sulfur dioxide. In some applications and thicknesses, hexavalent chromium plating can be replaced for trivalent chromium plating.

Hard Chrome and Decorative Chrome Plating Differences

Applications: Industrial settings with high levels of stress are ideal for hard chrome plating. For many consumer goods, however, decorative chrome plating gives the desired appearance and level of protection.

Thicknesses: The finished item’s chrome plating thickness is the main distinction between hard and decorative plating.

Properties: The strength and hardness of materials coated in hard chromium are increased. And your components look better with decorative chrome plating.

Chrome Plating Process with Features

Surface Preparation

- 2 different ways of Surface preparation Sandblasting and Etch-blasting.

- Sandblasting (roughing an area through the use of sand driven compressed air or steam).

- Etch-blasting (etch-blasting is achieved by setting a blasting cabinet air pressure to 30-40 psi).

Cleaning and Degreasing

- Cleaning and degreasing chrome plated steel to prevent rust and oxidation that leads to degradation.

- Cleaning chrome at least once a week helps the chrome stay in good condition.

Acid Bath or Etching

- Oxalic Acid Bath is a cheap method of cleaning rust on stainless steel.

- Etching is where the metal through a process of chemical reaction, is eaten away to create a pattern.

Nickel Plating

- Nickel plating helps protect the steel against corrosion and improve wear resistance.

- Nickel plating enhances the appearance by adding brightness.

Utilization of Chrome Plating

- Cleaning and Degreasing the Steel After thorough cleaning, place the metal in a chromium anhydride container, where it will acquire an electrical charge, sparking a chemical process that causes the chromium to attach to an object.

Final Polishing

- After the application, the final step is polishing the chrome plated steel by buffing, cleaning and coating for adhesion.

The Benefits of Chrome Plating in General

Enhanced Aesthetics

- The item appears more polished and sophisticated when it is coated in chrome.

Durability and Corrosion Resistance

- Due to its increased thickness, chrome-plated steel resists corrosion well against most materials.

- Chrome plating’s durability endures for decades, even under adverse circumstances.

Increased Hardness and Wear Resistance

- Chrome’s high hardness value makes it resistant to abrasion. A high corrosion resistance means minimal chemical assault and no metallic oxidation.

- Because it is low-friction and strong, hard chrome plating is incredibly wears resistant.

Additional Functional Advantages

- Improved Functionality

- Increased Value

Types of Chrome Plating

HCP (Hard Chrome Plating) Benefits

Oxidation Resistance: Because of its exceptional oxidation resistance, HCP is essential to the food, beverage, chemical, and pharmaceutical sectors.

Simple Re-plating: HCP has been eroded or damaged over time can be easily removed and replaced with etching chemicals.

Enhanced Hardness: HCP is more resilient than the majority of metallic coatings and industrial abrasives.

Strong Thickness: Whether machine parts are employed in typical operating settings or in extreme situations, HCP thick protects them from wear.

Minimal Friction: Friction is minimized when metal, plastic, carbon, and graphite come into contact with the HCP.

Abrasion resistance: Because of its high hardness and low friction, the HCP resists wear and abrasion even under extremely significant stress in mechanical contact.

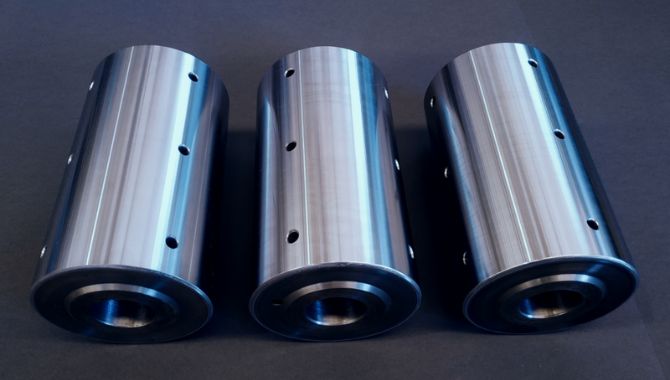

HCP (Hard Chrome Plating) Applications

Clutches: The low friction properties of HCP protect and enhance gear performance by lubricating it and extending its lifespan.

Filler Component: To guarantee that some worn parts regain their former dimensions, HCP is a helpful filler material.

Vehicle Industry: HCP is also used in the vehicle sector, especially on components like cylinders and shock absorbers.

Aircraft Industry: HCP parts are also frequently found here, such as landing gear and aluminum piston heads.

DCP (Decorative Chrome Plating) Benefits

Easy Maintenance: Since ornamental chrome plating is resistant to rust, it may be easily cleaned with common household cleansers and disinfectants.

Extra Visual Attractiveness: The part’s smooth, glossy surface is enhanced by the decorative chrome plating on it.

Great Efficiency: The decorative chrome plating shields the object against substances that cause oxidation, like chemicals.

DCP (Decorative Chrome Plating) Applications

Kitchen Utensils: The kitchen’s metal spoons, knives, spatulas, tongs, and forks are some uses of chrome plating.

Device Hardware: Instrument hardware, such as that found on guitars and clarinets, is plated in chromium to increase strength and give aesthetic appeal.

Tools: Ornamental chrome plating extends the life and resilience of tools and equipment.

Automotive Components: A variety of automotive parts, such as trim, door handles, rocker panels, bumpers, and grilles, are chrome-plated.

1. Using Specialized Machinery

In the first process, chromium is removed using a number of specialized machinery. This is the most economical option, even if it costs more.

- Abrasive Blaster Method

- Ultrasonic Cleaning Method

2. Using Chemical Solutions

Chemical treatments are less expensive option than specialized technology when it comes to removing chromium.

- Hydrochloric Acid Method

- Sodium Hydroxide Method

You can apply hard chromium plating to both ferrous and nonferrous metals. Including:

- High alloyed metals

- Stainless steel

- Cast irons

- Titanium alloys

- Bronze

- Brass

- Etc.

Due to several variables, chrome plating techniques can be quite costly.

The fact that this plating is an electrolytic process is the most crucial of these variables. Thus, electricity is required at all layers of plating.

It could take a day, this comprises prepping the metal, getting the chrome bath ready, correct plating, and finishing.

The procedure is lengthy and arduous. The payoff is tremendously satisfying, but it requires a lot of patience.

Many component elements of oil exploration and production gear are chrome plated to lengthen their service life and prevent price downtime.

Chrome-plated shafting is used in hydraulic equipment to improve service life in harsh industrial conditions.

Maintenance, usage, and weather patterns are some of the aspects that affect how long chrome plating lasts.

Chrome-plated surfaces can last for many years if properly maintained.

Damaged chrome plating can sometimes be rectified by re-plating or re-polishing. The amount of the damage, on the other hand, will affect the viability of repair.

A professional assessment is recommended.

Traditional chrome plating procedures use dangerous chemicals like as chromic acid, which can be damaging to the environment.

However, there are less dangerous chromium alternatives, such as trivalent chrome plating.

A substance will not corrode if it is plated with chrome. Chrome plating is used for rust-prone applications such as auto body parts.

The automotive industry consumes the most chrome.

Hard chrome plating leaves behind a chromium layer that ranges in thickness from:

- 0008 to 0.0050. The outside of the metal is (between 0.020 and 0.127 mm) thick.

Conversely, thin dense chromium plating comes in a thickness that varies from:

- This ranges from 0.0002 to 0.0006 inches (0.005 to 0.015 mm).

Overall Application of Chrome Plating

Automotive Industry

- Corrosion Resistance on steel parts

- Wear Resistance

- Tarnish preservation

- Metallization of plastic parts

- Promotion of coating adhesion

Household Items and Fixtures

- Chrome plating provides increase corrosion resistance and surface hardness, it also provides aesthetic and decorative purpose.

- Chrome plating is used in these following items. (Doorknobs, Shower Fittings, Interior and Exterior Lighting, toilet flush and chains.)

Industrial Machinery

- Hydraulic Cylinder

- Mining Equipment

- Shafts and Rotors

- Agricultural

Decorative and Customized Uses

- Used in Customized motor parts

- Bright Appearance

- Metal Furniture

- Hand Tools

Environmental and Safety Considerations

Environmental Impact

- Chrome Plating uses harmful chemicals such as hexavalent chromium, which is harmful if released into the environment without proper containment.

- Chromium can be toxic.

- Chrome plating uses toxic acid baths which is harmful to a person and may cause various health conditions.

- Hazardous substances.

Safety Measures and Regulations

- Air Monitoring

- Personal Protective Equipment (PPE)

- Product Substitution

- Reduce Mist Generation

- Respirators

Sustainable Practice and Alternative

- Alternatives

- Dull-Nickel Plating

- Bright-Nickel Plating

- Nickel Tungsten

Maintenance and Care of Chrome Plated Surfaces

Cleaning Methods

- Streaks and Grease and fingerprints can be removed by using either soap and water or vinegar

- Use sand paper to remove rust

- Wet Sanding

- Washing/Rinse Off

- Polishing

- Buffing the Chrome

Preventative Maintenance

- Washing Chrome Plated Steels on a Weekly basis

- No ammonia based or acid cleaning solutions

Restoration and Repair Techniques

- Sandblasting the rusted part

- Using Sandpaper manually (180-320 grit sandpaper)

- Isolate the rusted part

- Scrape of rust

- Treat metal

- Clean Chrome

- Treat the rust/Put metal polish

- Let the metal polish dry

- Buff the chrome

- Polish the chrome

Future Trends and Innovations

Advancement in Technology

- Because of its benefits over alternatives, the improvement of the chrome plating technology is still expected.

- According to the Global Chrome Plating Market, the Chrome Plating Market is expected to grow over the next five years. And new applications for chrome plating would be recognized.

Potential New Applications

- Military Advancements

- Metal Manufacturing

- Sanitary ware

Conclusion

Electroplating chromium into other metals is known as “chrome plating.” Natural in nature, chrome is a silvery-white metal with a hint of blue; it forms a thin film on surfaces and neutralizes in the air with ease.

The chrome layer improves look, boosts toughness, and makes maintenance easier. There are several commercial and industrial uses for the chrome plating process. With the Chrome Plating, turn the ordinary into the spectacular! Enhance your surfaces with unparalleled luminosity and long-lasting durability.