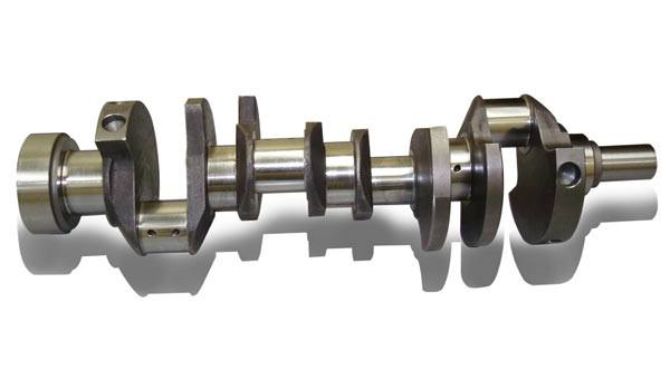

Do you know how a vehicle changes reciprocating motion into rotational motion – well, that is the role of a crank shaft.

In this guide, you are going to learn everything about this essential power transmission accessory in automotive engines. Whether you want to learn about the working principle, parts, features or functions – you will find all information right here.

Types Of Crankshafts

Let me put this out there. There are different types of engines. Crankshafts find its applications in different areas. For this reason, there is no one version of it.

Now let us discuss these types in detail:

Crank Shaft Components

Single Piece

It is made from one solid block of material. They are suitable for use in high and moderate speed engines. Besides, they are resilient and can withstand misalignment of bearings or axial vibrations.

Forged

Forging entails application of forces the metals to shape the final unit. This means welding is not a necessity. They are suitable for medium speed engines like generators. Besides, you can harden forged crankshafts through induction.

Semi-built

Here, you will not assemble all the parts in unison. Some components are fabricated together as a unit. For example, you can fully forge, shape, and build the primary bearings and the crank arm.

They are popular for making diesel engines for ships.

Welded

As the name suggest, you will connect different components of the crankshaft through welding processes. These units are strong but expensive, making them less preferred.

Cast

These systems are affordable to fabricate than other crankshaft versions. This makes them popular in engines that use diesel or petrol.

To make them, you will cast iron that is malleable. Also, you can improve its longevity by subjecting it to heat treatment. This in turn minimizes wear and tear, and enhances tensile strength.

Built up

This system comprises of several pieces that are made separately. As an example, you may perform machining separately on journals and crankpins. Afterward, you will heat, then artificially shrink fit them.

As they cool, they form a tight fit on each other.

Billet

To make this crankshaft, you will use 4340 type of steel alloy. This comprises of molybdenum, nickel, aluminum, and chromium.

They require minimal time to machine and can relay the maximum power available to loads. Furthermore, they operate well with minimal balancing.

Suitable Materials For Fabricating Crankshafts

These units need to be strong because of the forces they endure. Some primary materials that are suitable for its construction include the following:

- Carbon steel

- Steel alloy

- Nickel chrome

Within carbon steel, you can add other components such as:

- Manganese

- Silicon

- Chromium

- Cobalt

- Molybdenum

- Vanadium

Manufacturing Process Of A Crankshaft

As you already know by now, there are several types of crankshafts. This means the manufacturing process will vary from one version to another. We will explain common steps below:

Step 1

The first step entails casting or forging the crankshaft. When you opt for forging, you will heat the metal then bring it to shape.

Casting entails using a mould that will shape molten metal. Once it cools, it takes the shape of the mould.

Side note: Performance engines may prefer using forging as the manufacturing method. Engines that require high performance opt for billet crankshafts. These are expensive to manufacture.

Step 2

After forging or casting the crankshaft, you will smooth out areas for the bearing and journals. Afterward, you will drill oil passages.

Furthermore, when making production engines, you may decide to leave the rough finish of the cast on the webs. However, you will machine parts of performance engines. This helps minimize oil drag.

Step 3

Here, you will ensure that journals are harder than bearings. This is to make sure that wear and tear does not occur on crankshafts, but on bearings.

Using heat treatment process is one way to harden such areas.

Components Of Crankshafts

A crankshaft is not a solitary component. Many parts come together to make is a fully functional system. Her are the parts you will find in this unit:

Parts of Crank Shaft – Photo courtesy: The Engineers Post

Oil Passage

These are holes that provide lubrication to the system thereby minimizing rate of wear and tear. They sit on the crank web and release oil when the system is operational.

Thrust Washers

These components sit between the crank saddle and the web. They maintain the space between two adjacent crankshaft parts.

Oil Seals

They serve the purpose of containing oil in the right places therefore preventing any leakages. Two types of oil seals are used:

Oil Seal on the Front Side

This seal sits behind timing gears and pulleys. When it fails, you can easily trace and repair it.

Oil seal on the rear side

This sits between flywheels and main journals. A garter spring holds this seal in place between crankshafts. When it fails, it is generally hard to reach and repair.

Balancing/Crank Weight

They sit on the crank web and assist in improving the unit’s stability. This means the system can operate smoothly even at higher rpm.

Crank Web/arm

This arm serves as a connection between the crankshafts and journal bearings.

Throws

They are also known as crank pins. Their aim is joining crankshafts to connection rods. It plays the major role of delivering rotational force to the connecting rod’s bigger side efficiently.

Flange Mounting

Flanges connect crankshafts and flywheels.

Main Journals

These parts are linearly placed to the crankshaft. You will use this component to attach this rotating shaft to the engine block.

Working Mechanism Of A Crankshaft

These systems have several components that work together to transfer power. Here is a breakdown on how it operates:

- The crankshaft has a series of offset pins or “journals” spaced around its circumference. These journals are offset from the center of the crankshaft.

- As the engine runs, the pistons move up and down in their cylinders. Hence, they push and pull on the connecting rods.

- The connecting rods are attached to the crankshaft journals. As the pistons move up and down, the connecting rods push and pull on the journals in a rotating motion.

- Because the journals are offset from the center of the crankshaft, the pushing and pulling of the connecting rods causes the crankshaft to rotate in a circular motion.

- The rotating crankshafts transfer momentum from pistons to the transmission units. This in turn drives the wheels of the vehicle or powers other equipment.

Lubricating Crankshafts

The crankshaft have several moving components. This means it needs to operate efficiently so power can be transferred without any loss. In addition, smooth operation minimizes damage in the engine.

For this reason, lubrication of the crankshaft is vital. As the metal parts move up and down, lubrication oil makes the process as smooth as possible.

Reasons for Crankshafts Failure

The design of a crankshaft is to make it efficient for a long time. However, there are moments some extreme cases may cause it to operate below standard, or fail.

Here are some issues that may make this unit fail:

Vibration Induced Failure

The journal and crankpins can fracture when the engine experiences a lot of torsional vibration.

Worn Out Journals

This happens when the oil pressure is inadequate. Journals and bearing surface rub against each other. The effect of this is that the gap widens and the oil pressure lowers.

Fatigue

These are forces that constantly pile up on the crankshaft that may cause fractures to appear. It primarily happens on the joint between the wen and journals. Magna fluxing is one way of inspecting for such failures.

Too much Pressure in Cylinders

Hydraulic lock happens within the liner because of excess crankshaft pressure.

Minimal Lubrication

This will increase friction thus damage the bearings.

Misalignment Of Crankshafts

Parts within this unit may not align to one another thus cause inefficiencies. Some reasons for this include:

- Explosion or fires within the crankcase

- A damaged primary bearing

- Bolts that have broken or are not tight

- Cracked bearing saddles or pockets

- Corrosion in the unit

Alignment in Crank Shaft

How Crankshaft Vs Camshaft Compare

In an engine, you will find these two systems coordinating to realize a collective goal. We have a comparison table that shows how they compare:

| Crankshaft | Camshaft |

| It transmits power | It actuates intake and outlet valves |

| Driven by pistons via connecting rods | Driven by crankshaft via timing systems |

| Main material is steel alloy | Material construction is cast iron or steel |

| Sits beneath engine cylinders | Sits above engine cylinder |

| Handles high torque | Needs less torque to operate |

| With one power stroke, it revolves twice in a 2-stroke engine | With one power stroke, it revolves once |

| One engine requires one crankshaft | One engine can work with one or two units |

| Used in both 2 and 4-stroke engine | Used only in 4-stroke engines |

| Heavy | Light |

Applications Of Crankshafts

Crankshafts are versatile components of a machine. This means it finds its application in several areas. Some of them include:

Diesel Machines

The components here are large and are made through forging alloy steel. This means they can withstand long usages and provide power efficiently.

Generators

These components are available within electric generators. It changes the motion of pistons to rotary motion. Normally, the flywheel will turn due to this rotational force.

Consequently, this will generate power. Alongside the alternator the generator will produce an electrical power.

Combustion Units

This system can sit within an engine block that burns to produce power. It will help it transfer motion from linear to rotational through the use of rods. This allows you to provide power that runs different loads.

Camshaft Drives

Crankshafts and camshafts work together. Driving units like chains assist in relaying power from crankshafts to camshafts.

Motorbikes

The system helps motorbikes move and lower vibrations in the engines.

Power Transmission

A crankshaft makes it easy to relay power to other parts of an engine. Some of these parts include compressors, valve timings, and pumps for air and water.

Crank Shaft

What does a crankshaft position sensor do?

Determine the position and/or rotational speed (RPM) of the crank.

How to Test Crankshaft Position Sensor?

Attach it to the sensor and crank the engine.

What is a V8 Crankshaft?

Two banks of four cylinders share a common crankshaft and are arranged in a V configuration.

Crankshaft Position Sensor Location

In the timing cover or on the side of the block.

Conclusion

It is now clear how important a crankshaft is to an engine. And how it supports several engine operations. We also hope that this guide has given you in-depth knowledge to the workings of a crankshaft.

More Resources:

Crank Shaft Parts – Source: The Engineers Post

Crank Shaft – Source: Wikipedia

Automotive Engine Materials – Source: Science Direct

Structure and Function of Crank Shaft – Source: Motor Service

What is a Crank Shaft – Source: MTAQ