Laser cutting machines have become a vital tool in the modern production and fabrication industries. These machines are offering precision, speed, and versatility. Hence, allowing more efficiency and productivity for small or large businesses.

This article aims to help you understand the different factors that affect the price of a laser cutting, from machine type, power, to additional features. It will also help you choose the right laser cutting machine that you can benefit the most. Whether you are a business owner considering purchasing a laser-cutting machine, this article is for you.

Scroll down to read and learn more!

What is Laser Cutting Machine

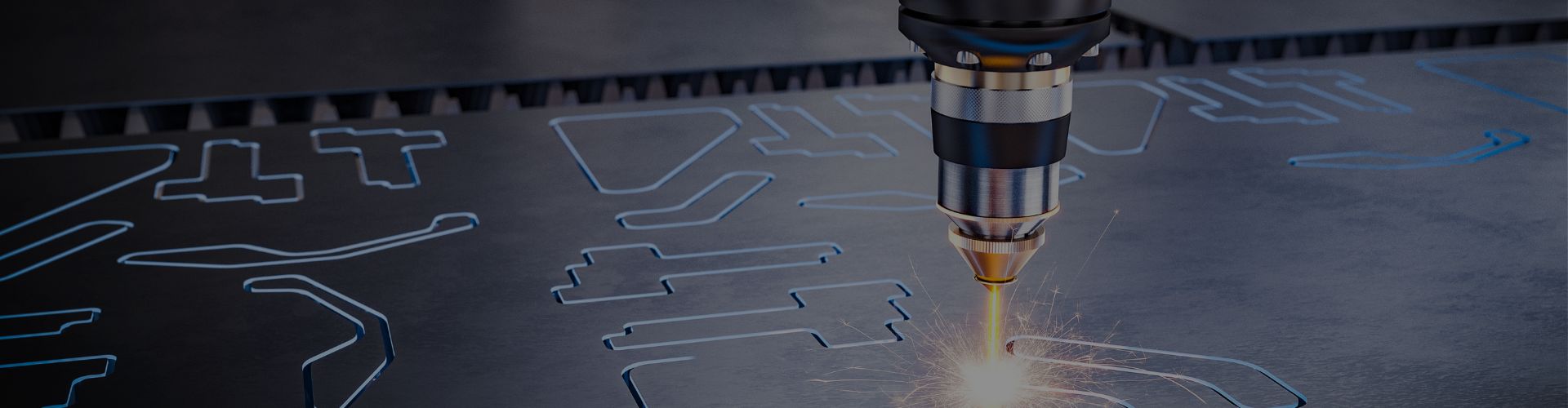

The primary function of laser cutting machines is to cut metals or non-metal materials with high accuracy and speed. Thus, making it a precision tool commonly used in the fabrication and manufacturing processes.

These machines are equipped with cutting edge and high-powered laser beam. Allowing materials to have a clean and precise cut. It can cut materials through melting, blowing, and vaporizing.

The overall price of a laser cutting machine will depend on its capabilities, features, and other important characteristics.

Average Price of Common Laser Cutters Available in the Market

Laser-cutting machine prices in the market today can range between $3000 to $1000000. This price range depends on various machine factors.

The price range can be a little overwhelming. However, understanding the different factors influencing their prices can help you choose the right machine for your applications.

Different Factors that Affect the Price of Laser Cutting Machines

The different influencing elements below can help you determine the price of the laser cutters.

Type of Laser Used in the Machine

Laser cutting machines are integrated with various laser types such as diode, fiber, and CO2. These laser types come with different functionalities and therefore, also come with varying prices.

CO2 laser cutters are widely known because of their versatility when it comes to cutting non-metals. It is best for fabrics, MDF, acrylics, and more. It functions in both cutting and engraving.

On the other hand, fiber lasers provide efficiency in cutting metals like carbon steel and stainless steel.

Furthermore, diode lasers are cost-effective machine when it comes to smaller projects. Thus, making it perfect for hobbyist and DIY makers.

The specific types of lasers mentioned above have a great impact on the machine’s cost.

Features

The laser cutting machine’s price can escalate if it has features such as:

- Intuitive user interface

- Built-in design software

- Safety features

Power Output

A laser cutter’s power output (kW) is closely linked to its capabilities. The higher the power output, the more capability it can cut thicker materials at a high speed. A sheet metal laser cutting machine with high power output is especially beneficial for sheet metal fabrication. It is important to note that the enhanced capabilities often come with higher prices.

Size

Laser-cutting machines in the market are available in different sizes. You can choose from industrial laser cutters for mass production and compact desktop cutter machines for small businesses.

The laser-cutting machine’s size directly impacts its overall cost. The bigger the machine, the bigger its cost due to its robust construction and enhanced capabilities.

Machine’s Axes

Precision is very crucial when it comes to cutting materials with intricate designs. A laser cutting machine with several axes can create complex cuts and designs with maximum flexibility. However, it is more expensive since the number of axes can influence the overall machine cost.

Speed

For large businesses that deal with mass production, a laser cutting machine’s speed is very crucial. However, laser cutters that are designed for fast turnover often have higher costs.

Machine’s Work Table

The size of the laser cutting machine’s work table indicates how much material it can accommodate. Bigger work tables are suitable for large projects. It is also ideal for batch processing of smaller items. It is important to take note that larger work tables have higher prices.

Precision

Laser cutting machines with higher precision are typically more expensive yet very crucial for making intricate designs.

Workpiece Material

Several workpiece material needs a specific type of laser used in the machine. Therefore, if you want a versatile laser cutter, you can expect it to have a higher price.

Services and Support

The support services that are offered after your purchase of laser cutting machines can influence the overall value you can get. Services such as after-sales support encompasses training sessions and inspections. These services are usually indispensable, especially for novice operators. This entails a higher buying price.

Brand

The laser cutting machine brand can have a notable impact on its cost. Machines come from well-established brands known for their cutting-edge advancements, trustworthiness, and longevity, and often come with a higher price tag.

Automation Level

Automation level of a laser cutting machine such as computer-controlled settings, material recognitions, and more can enhance your user experience. However, these cutting-edge features can naturally increase the price of the machine.

Different Types of Cutting Machines and Its Cost

These machines are excellent in processing non-metal materials such as fabric, wood, and acrylic. CO2 laser cutters can offer advanced cutting technology and efficiency in handling intricate details with precision.

CO2 laser cutting machines’ prices are ranging between $8000 up to $50000. In this price range, you can expect a machine with 100W up to 500W power output.

These cutting machines are designed with laser beams generated by Neodymium-dope Yttrium Aluminum Garnet (Nd: YAG) crystals. Therefore, you can ensure versatility and ability to cut or engrave a variety of materials including metals, ceramics, plastics, and more.

Nd: YAG laser cutters are also popular for their fine and precise cutting, allowing them to have prices ranging from $40,000 up to $300,000.

Diode laser cutters are often a cost-effective option for several businesses since their cost only ranges from $5000 up to $20,000.

These machines are integrated with semiconductor diodes that generate a laser beam. The laser beam produced is used for cutting and engraving different materials.

Fiber laser cutters are specially designed for cutting metal materials such as stainless steel, brass, and aluminum. This machine typically has 500W up to 20kW power outputs.

The fiber laser cutting machines are usually priced between $20,000 up to $500,000.

This type of laser cutting machine is designed with a power output ranging from 0.5kW to 2kW. Thus, making it ideal for small businesses and beginners. Entry-level laser cutters cost $3,000 up to $10,000.

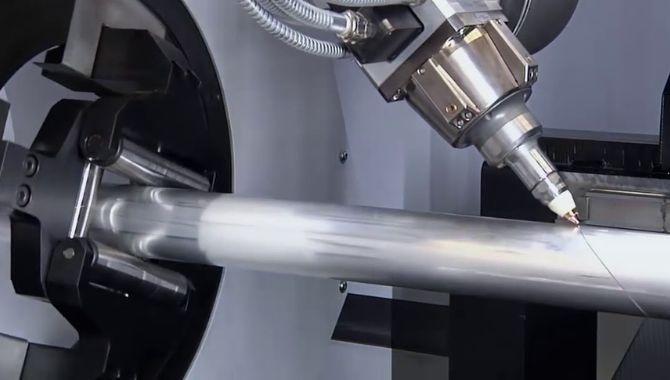

These machines offer precise, accurate, and clean cutting of tubes. Tube laser cutters are commonly used for automotive and furniture industries. It typically cost around $30,000 up to $200,000.

Laser-cutting machines designed for hobbyists offer both cost-effectiveness and precision. This machine is ideal for craft enthusiasts, personal projects, and DIYers. The price range of hobbyist laser cutters is from $500 to $3500.

These machines offer both functionalities of industrial and entry-level laser cutter models. It serves the needs of businesses seeking advanced features at an affordable cost compared to industrial laser machines. The price of a mid-range laser cutter ranges from $10,000 up to $50,000.

Industrial laser cutters are powerhouses in the world of manufacturing. They can accommodate heavy-weight tasks effortlessly such as processing carbon steel and stainless steel. This machine costs from $20,000 up to $500,000.

Laser cutting machines designed for metals are customized to deliver robustness and accuracy. It also offers precision, especially in various metal fabrication. Metal laser cutters typically cost between $15,000 up to $300,000.

Small laser cutters are an excellent choice if you are looking for affordability and high efficiency in a smaller machine. This machine’s cost ranges from $2000 up to $15000.

Choosing the Right Laser Cutting Machine

To make the right choice, consider the following critical aspects:

Material Compatibility

Determine the types of materials you intend to work with. Some laser machines are optimized for metals, while others excel with non-metal materials like plastics, wood, or fabrics. Ensure your chosen machine aligns with your material needs.

Cutting Power

Evaluate the power output of the laser cutter, usually measured in watts (W)

or kilowatts (kW). Higher power typically allows for cutting thicker materials and faster processing. Choose a power level suitable for your specific applications.

Machine Size

Consider the physical dimensions of the laser cutter, as it should fit within your workspace. Compact models are ideal for small workshops, while larger machines are suitable for industrial settings.

Budget

Determine your budget range. Laser cutting machines come in a wide price spectrum, depending on their capabilities and features. Balance your requirements with cost considerations to find the best fit.

Cutting Area

Assess the size of the cutting bed or workspace. Ensure it accommodates the dimensions of the materials you plan to work with. Larger cutting areas offer more versatility.

Conclusion

In conclusion, the cost of a laser cutting machine varies widely depending on factors like type, power, and brand. It’s essential to match your machine choice with your specific needs and budget. Whether you’re a hobbyist, a small business, or an industrial operation, understanding the cost factors will help you make a wise investment in this versatile and precise tool for material processing.