Why Laser Etching?

The power of laser etching has been grossly underestimated in the manufacturing industry. A lot of manufacturers get stuck in traditional etching methods but for your sheet metal fabrication to stand out, you need to maximize the power of laser etching to create high-quality designs and patterns with high precision.

Do you want to discover how to increase the accuracy of your metal fabrication? This guide explicitly explains the technology of Laser etching and how its power can be utilized in fabricating your sheet metal.

Role of Precision in Sheet Metal Fabrication

For you to produce high-quality end products, there are processes you must follow during sheet metal fabrication. To achieve this, high-level precision is required because one mistake can alter the entire process.

Precision is of utmost importance in sheet metal fabrication due to the following reasons:

- Quality: The slightest error in measurements or cutting can result in defective products.

- Functionality: Parts that do not fit together properly can cause the product to malfunction or fail.

- Time: When parts are fabricated precisely, they fit together perfectly, which speeds up the entire production process.

- Safety: When parts fit together accurately, there is less risk of the product failing or malfunctioning and causing injury to you.

- Aesthetics: Precise fabrication can improve the appearance of your sheet metal parts, which is important for products that are visible to customers.

Importance of Laser Etching in Sheet Metal Fabrication

The process of laser etching involves utilizing a focused beam of laser to make an impression on a material’s surface, resulting in a specific design or marking. Examples include stainless steel, jewelry, electronics, automotive parts, etc.

The laser beam is highly focused and concentrated and you guide it by a computer-controlled system. This allows for precision because the laser follows the exact pattern and design specified in the digital files.

Laser etching plays an important role in achieving precision in sheet metal fabrication by

- Achieving consistency: The technology of laser etching allows you to produce consistent and accurate results every time, regardless of the complexity of the design.

- Ensuring Sharp Edges: Laser etching allows for sharp and clean edges, which is particularly important when working with intricate designs or small components.

- Increasing Efficiency: With its fast and efficient capabilities, laser etching can expedite production schedules and enhance overall output, making it an excellent tool for boosting productivity.

Sheet Metal Fabrication Process

Cutting: you cut the sheet metal by disintegrating it into different parts. There are different cutting methods. Examples: laser cutting, waterjet cutting, punching, etc.

Deformation: This is the process where you shape sheet metal into various forms like cones, cylinders, or boxes. There are different deformation methods. Examples: bending, rolling, stamping, etc.

Assembly: This is the process where you join two or more pieces of sheet metal to create an end product. There are different assembly methods. Examples: welding, brazing, soldering, etc.

Comparison of Traditional Etching Methods to Laser Etching

When it comes to etching, laser technology is considered superior to conventional techniques such as chemical etching.

| Traditional Etching Methods | Laser Etching |

| Involves using chemical or acid-based solutions to selectively remove material from the surface of the metal. | Uses a computer-guided laser beam to remove material from the surface of the metal precisely. |

| Can result in uneven etching and jagged edges. | Produces sharp and clean edges, allowing for intricate and precise designs. |

| Maybe less precise, leading to variations in the finished product. | Offers high precision, resulting in consistent and accurate results every time. |

| May be slower and less efficient, leading to longer lead times and higher costs. | Enables swift turnaround times and improved output capacity. |

| May be limited to certain materials, such as copper or brass. | Can be used on metal, plastic, wood, and more. |

How to Use Laser Etching in Sheet Metal Fabrication?

Understanding the Technology of Laser Etching

Laser etching involves using a focused laser beam to apply heat to a material, causing it to melt and allowing for the creation of a permanent mark on the surface of the material. You have to heat the surface first to leave a permanent mark on it.

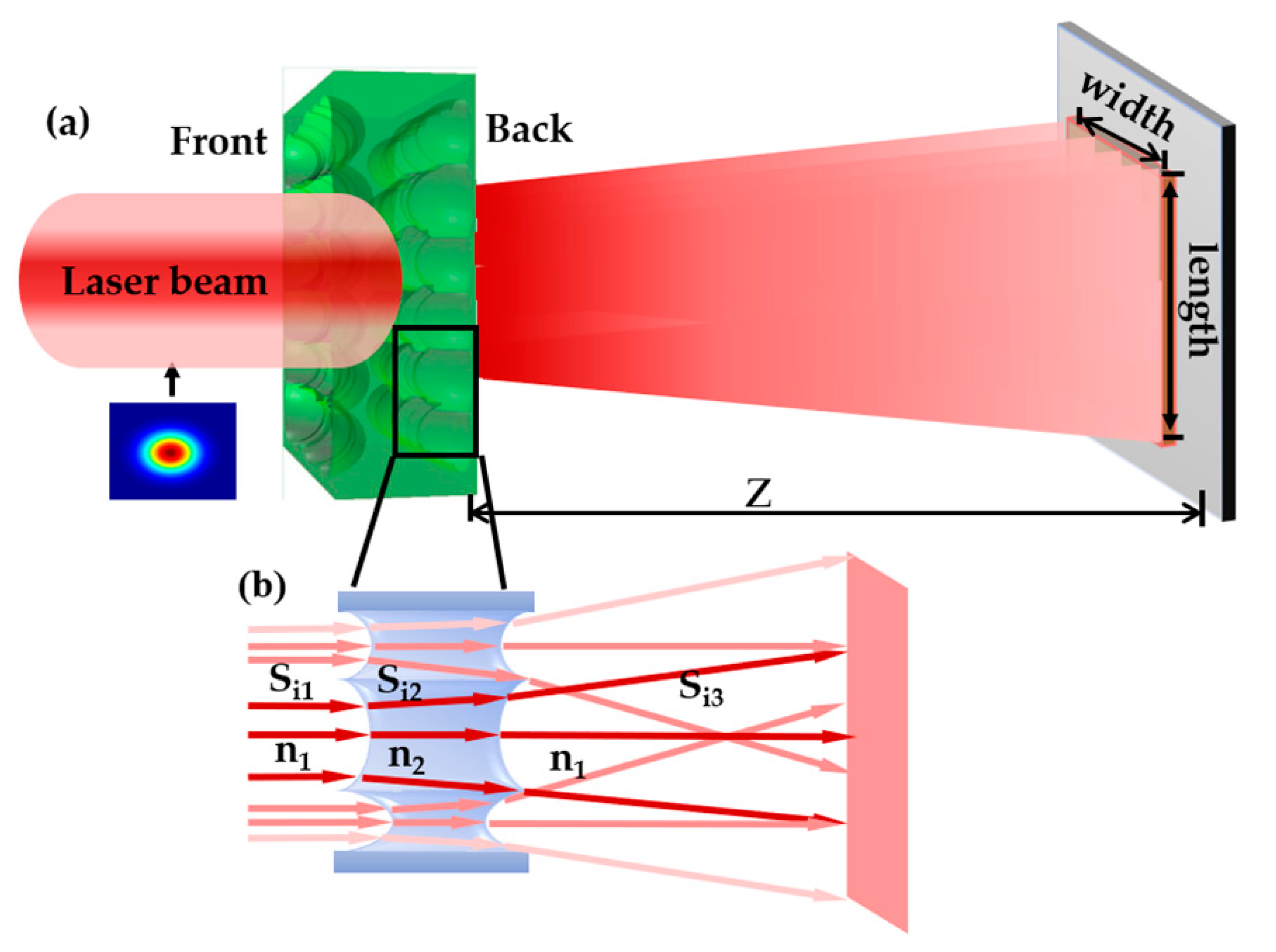

- A laser is a concentrated beam of light that is created when a material called the gain medium is excited by an outside source of energy, like electricity or another beam of light. This causes the gain medium to emit light in the form of photons.

- The photons emitted by the gain medium bounce back and forth between two mirrors at either end of the laser. This creates a concentrated beam of light that’s all traveling in the same direction and has the same color.

- When the laser beam is focused onto a material during laser etching, it gets really hot and vaporizes or melts the material. This is because the photons in the laser beam have a lot of energy, and when they hit the material, they transfer some of that energy to it.

- The amount of heat generated by the laser can be controlled by adjusting the power of the laser and how quickly it moves across the surface of the material.

How Lasers Work – A Complete Guide

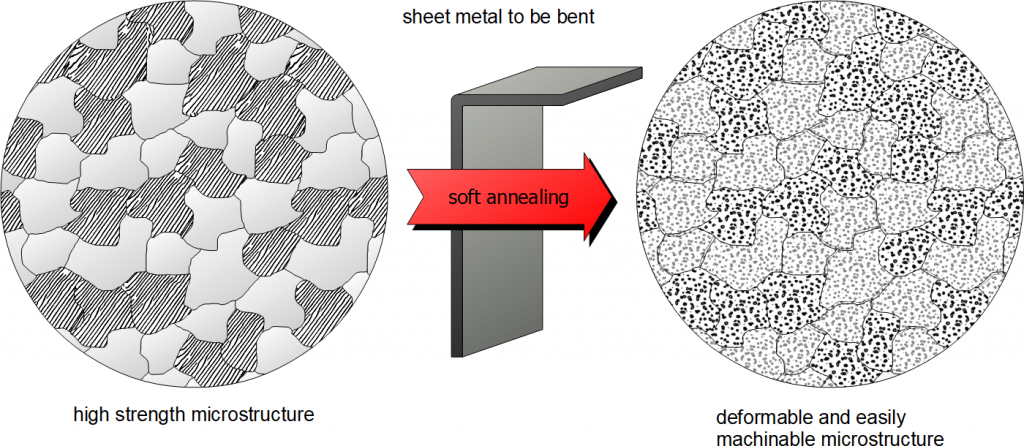

When you’re doing laser etching, you may notice that the color of the metal can change in the area where the laser has been used. This is due to a process called annealing.

- When you’re doing laser etching, you may notice that the color of the metal can change in the area where the laser has been used. This is due to a process called annealing.

- Annealing happens when you apply heat to a metal, causing the structure of the metal to change. This can happen at different temperatures for different metals, but generally involves the rearrangement of the atoms in the metal so that they form larger crystals.

- The application of a laser beam onto metal for etching purposes results in the concentration of significant thermal energy within a confined region. This can cause the metal to undergo annealing in that area, which can change its color.

- The exact color that you see will depend on a number of factors, including the type of metal that you’re working with, the temperature of the laser beam, and how long the beam is applied to the metal.

- For example, if you’re working with stainless steel, you may notice that the metal turns a brownish color in the area where the laser has been used. This is because the heat of the laser has caused the metal to undergo annealing, which changes the way the metal reflects light and creates a brownish color.

Now, it’s worth noting that the color change that happens during laser etching is usually a surface effect. That means that it doesn’t penetrate very deep into the metal. Depending on the exact process that you’re using, you may be able to remove the color by polishing or buffing the surface of the metal.

Comparison to Other Laser-Based Processes

You can delve into various techniques utilized in the fabrication of sheet metal. Laser etching is just one of them. Examples: laser cutting, laser engraving, and laser welding.

| Process | Description | Advantages | Disadvantages |

| Laser Etching | Uses a computer-guided laser beam to melt the surface of metals |

|

|

| Laser Cutting | Uses a laser beam to cut through the sheet metal. |

|

|

| Laser Welding | Uses a laser beam to melt and join two pieces of sheet metal together. |

|

|

| Laser Drilling | Uses a laser beam to drill precise holes in the sheet metal. |

|

|

Importance of Quality Control in Sheet Metal Fabrication

Quality control ensures that your final product meets the required specifications. It involves steps like regular calibration, inspection, and testing of the finished parts to identify and fix any defects. Some of the important ones include:

- Ensures product reliability and safety

- Minimizes waste and rework

- Improves customer satisfaction

- Enhances competitiveness

- Supports continuous improvement

Pros of Laser Etching in Metal Fabrication

Speed

A lot of people keep asking questions like “how fast is laser etching? The speed of a laser beam in a vacuum is constant and approximately 299,792,458 meters per second (or about 186,282 miles per second). Systems with higher laser power are way faster.

Cost-Effectiveness

Laser etching can help you save more money because its speed helps increase productivity in a short time and can as well be used to create various designs and patterns which reduces the need for other methods.

Improved Precision and Accuracy

Both precision and accuracy are important when it comes to laser etching. You want the machine to be consistent in its results (high precision), but you also want it to be able to recreate the designs you have in mind (high accuracy).

Enhanced Efficiency and Productivity

You can create intricate designs quickly and easily as a result of the automated process and the high speed of laser etching.

Flexibility and Versatility

Laser etching can work on many materials. Examples are metals, glass, plastic, wood, and leather.

How to Create Precise and Intricate Designs

How Laser Etching can be used to Create Complex Designs

Here are detailed steps on how you can create complex designs with laser etching:

- Create a digital design: to do this, you have to make use of soft wares like Adobe illustrator.

- Chose the right material: some materials you can use includes wood, plastic, metal, glass, etc.

- Set up the laser etching machine: you have to adjust the laser power, speed, and focus.

- Load the digital design: here, you import the file into the design software and confirm the layout and object settings.

- Etch & finish: to do this, you etch the design onto the chosen material and finally finish the design. For example, you may need wood to be sanded or sealed.

Importance of Design Soft wares and Programming in Laser Etching

Design soft wares such as CorelDraw will allow you to create designs that can be scaled, edited, or exported.

Programming soft wares like laser CAD will as well allow you to have total control of the laser etching machine. You have the power to determine the laser power, setting, and path of the laser beam.

- Design software enables the creation of precise and intricate designs

- Programming ensures the accurate execution of designs

- Enables customization and personalization

- Increases efficiency and productivity

- Supports innovation

Finding the Perfect Laser Etching Machine: Key Factors to Keep in Mind

Important Factors in Selecting a Laser Etching Machine

It’s very easy to make a mistake when choosing a laser etching machine. Some factors you must consider include laser power, precision and accuracy, automation, maintenance, and support.

Power, Speed, and Accuracy Considerations

Remember we said the higher the laser power, the faster the speed. You want to ensure the machine you select has the appropriate power.

You also want to consider the desired speed of production as this allows for more designs in a shorter time.

Precision is another factor you must consider. The higher the accuracy, the more detailed your designs will be and the less likely it will be for errors to be made.

Cost and Maintenance Considerations

It is important to consider your budget and the long-term ROI of the laser etching machine.

You must consider the ongoing maintenance requirement of the laser etching machine you’re looking to purchase.

Guide for Successful Laser Etching

Preparation and Cleaning

By properly preparing and cleaning the sheet metal, you can ensure that the laser etches the design accurately.

Proper Machine Setup and Calibration

You have to ensure the laser etching machine is rightly positioned in a well-ventilated area with adequate space and that the laser beam is properly calibrated to ensure it’s hitting the surface of the material correctly.

Safe Handling and Maintenance of Laser Etching Machines

To ensure the longevity and optimal performance of the machines as well as the safety of the operator, you have to safely handle and maintain the laws etching machine.

Materials Suitable for Laser Etching

- Metals: Stainless steel, aluminum, brass, copper, and titanium.

- Plastics: Acrylic, polycarbonate, ABS, and other plastics.

- Wood: Plywood, MDF, bamboo, and hardwoods.

- Glass: Wine glasses, mirrors, and other glassware.

- Ceramics: Porcelain, earthenware, and other ceramics.

- Leather: Wallets, bags, and belts.

- Stone: Granite, marble, and other stone surfaces.

- Fabric: Certain types of fabric, such as denim.

- Paper: High-quality paper.

Limitations of Laser Etching for Certain Materials

Here are some limitations of laser etching for certain materials:

- Metals: Some metals, such as gold and silver, are difficult to laser etch because they reflect too much light.

- Wood: Laser etching can create dark burn marks on some types of wood, which may not be desirable depending on the desired outcome.

- Glass: Laser etching on glass can be limited by the thickness and type of glass used. Additionally, some types of glass may not produce the desired contrast or depth of etching.

- Ceramics: Ceramic surfaces can vary greatly in hardness, which can affect the ability to achieve consistent results with laser etching.

- Leather: Laser etching on leather can be limited by the type of leather used and the desired contrast or depth of etching.

- Stone: The hardness and color of stone surfaces can affect the outcome of laser etching, and some stones may not produce the desired contrast or depth of etching.

- Fabric: Certain types of fabric may not produce sharp, precise results with laser etching and may require pre-treatment or special coatings to achieve the desired outcome.

- Paper: High-quality paper can be laser etched effectively, but the thin or low-quality paper may not produce sharp, precise results. Additionally, the paper may become brittle or discolored.

Best Practices for Preparing Sheet Metal for Laser Etching

Sheet Metal Fabrication Steps

To fabricate a sheet, the first step you take is to cut the sheet metal into the required size, afterwards, the edges are smoothed out by deburring.

Cleaning and Surface Preparation

Cleaning helps you ensure the metal surface is free of contaminants and has the right surface finish. You can achieve this by degreasing, sandblasting, pickling, grinding, electroplating, and phosphating.

Masking and Stenciling Techniques

These are techniques that help you create a pattern or design on the metal sheet surface by covering certain areas and leaving others exposed e.g. tape masking, liquid masking, etc.

Conclusion

By now you must have understood how laser etching works and how you can use it in your sheet metal fabrication to achieve the highest level of accuracy. There are other laser-based processes you can choose from but Laser etching is known for speed, precision, and versatility in sheet metal fabrication.

If you are looking for a precise way to create intricate designs, you might want to consider it. To get an expert to guide you in getting started with laser etching, Contact us now and get all the help you need.