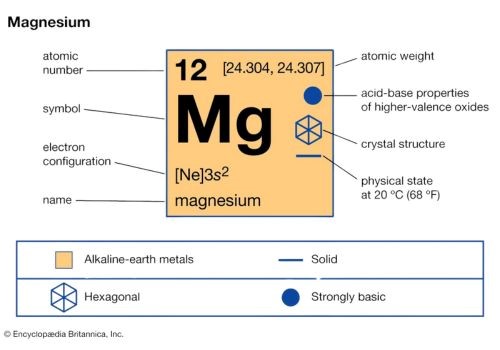

The eighth most abundant earth metal is magnesium (Mg) which also tends to be lightweight and to possess properties that make it unique. It is also a gray-white metal with a high melting point.

The Magnesium Melting point:

- 650 degree Celsius

- 1202 degrees Fahrenheit

Properties of Magnesium

It has low density which is two-thirds against aluminum. This makes it one of the lightest metal in the periodic table.

| Property | Value |

| Atomic Number | 12 |

| Boiling Point | 1090 °C (1994 °F) |

| Electronegativity | 1.00 (Pauling scale) |

| Density | 1.74 gram/cm³ |

| Melting Point (Mg) | 650 °Celsius (1202 °F) |

Factors Affecting the Melting Point of Magnesium

Several types of factors usually impact the melting point of magnesium. Meanwhile, pure magnesium generally shows 650 °C (1202 °F) the melting point of it.

When you add different impurities in magnesium, such as iron or silicon, they can help in reducing the melting point. When you add other metals to pure magnesium, they become Alloys with different melting points.

For example, when you add aluminum to magnesium, the melting point increases. On the other hand, when you add zinc to the magnesium, the M.P. of magnesium decreases slightly.

Magnesium Alloys of Magnesium: Melting Point Ranges

The exact range of melting point still depends on the certain alloy composition.

| Alloy Type | Melting Point Range (°C) | Melting Point Range (°F) |

| Magnesium-Aluminum (Mg-Al) | 900°C – 1040°C | 1652°F – 1904°F |

| Magnesium-Manganese (Mg-Mn) | 620°C – 650°C | 1148°F – 1202°F |

| Magnesium-Zinc (Mg-Zn) | 590°C – 630°C | 1094°F – 1166°F |

Applications of Magnesium Melting Point in Industries

Adding different alloys can affect the melting points which can result in varying qualities to use in many industries. Generally, magnesium has many unique properties, which makes it perfect for different kinds of uses in many industries.

Meanwhile, aircraft also use magnesium in their components because of its lightweight nature and strength. It is used in the automotive industry for magnesium parts like wheels or engine components. This helps reduce vehicle weight and increase vehicle efficiency.

Also, if you notice the casings on your laptops or other electronic devices, magnesium works best to protect them.

When used in biomedical settings, magnesium is very important for taking care of your bone health. Its alloys are used in orthopaedic implants.

Recent Development in Magnesium Melting Point

There are some recent advancements in the magnesium melting point. For instance, adding magnesium to zinc improves performance properties of zinc.

These advancements have also improved the processing of magnesium alloys, which are critical for use.

| Aspect | Key Finding | Description |

| Ignition Point | Increased by 200-300°C | National Institute of Advanced Industrial Science and Technology achieved this through specific processing techniques (details not mentioned). |

| Properties at Melting Point | Density of pure solid Mg: 1.74 g/cm³ (at 20°C) | Density of molten Mg: 1.59 g/cm³ (at melting point) |

| SLM Process Challenges | Burning during SLM due to low melting point (923 K) | Alloying with other elements helps reduce burning. |

| Process Parameter Optimization | Molten pool size and laser power | Higher laser power increases pool size. Finding the right balance of power and speed minimizes defects like porosity and “balling” in SLM. |

Conclusion

When you compare it with other metals, it still has a low melting point. But its lightweight nature and best properties make it ideal for many uses. In the coming days, more discoveries about magnesium alloys will be made.

More resources:

Does Magnesium Rust – Source: KDM

Is Magnesium Magnetic – Source: KDM

Copper Melting Point – Source: KDM

Melting Point of Zinc – Source: KDM

Melting Point of Graphite – Source: KDM