Silver melting temperature will help you decide whether the material is suitable for a specific application of not.

Besides, this knowledge help metallurgists choose the right furnace for melting silver. In this guide, we explore some fundamental aspects about silver melting temperature.

Let’s dive right in:

What is the Melting Point of Silver?

The melting point of a compound, element, or solid substance is the point at which it turns into a liquid. Silver is one such substance with a melting point of 961.8°C.

If you prefer the Fahrenheit scale, then the melting point of silver is 1,763.24°F. This conversion is very vital, especially in applications and industries dealing with Fahrenheit as the SI unit.

In the science community, the melting point of silver is measured in Kelvin and given as 1,234.95 K. This scale of measurement gives out an absolute number.

Melting and Boiling Point of Silver

When trying to understand the melting point of silver, getting a good grasp of its boiling point is also a very crucial key property. The boiling point of silver is about 2,162°C which is equal to 3,923.6°F or 2,435.15 K.

These two properties demonstrate the element’s high heat conductivity that enables it to withstand high heat temperatures. This high-heat threshold makes it appropriate for high-heat applications.

Factors Affecting Silver Melting Point

There are very many factors that come into play when we are analyzing the melting point of silver. Let us break it down into some of the most significant factors:

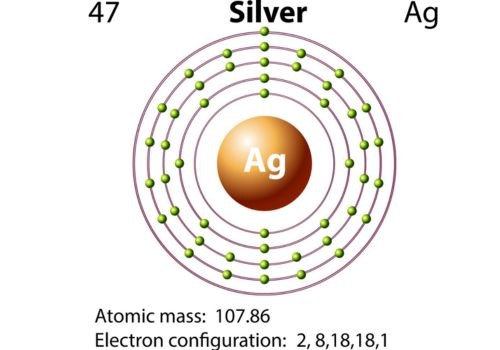

- Silver Atomic Structure: silver closely packed face-centered cubic (FCC) lattice with closely packed atoms that have an impact on its melting point. This structure offers it rigidity and a high mechanical strength making silver have a very high melting point.

- Atomic Size: the size of atoms defines the extent to which such atoms can be compressed into specific patterns of the crystal lattice. The atomic size of silver gives it very strong metallic bonds due to its small atoms in the solid form.

- Silver Purity: fine or pure silver or what is commonly known as pure silver contains 99.9% of silver and has a standard melting point of 961.8°C. Some of the impurities or alloying elements can cause the lowering of the melting point because they distort the orderliness of pure silver.

- Isotopic Composition: silver is composed of two stable isotopes namely Ag-107 and AG-109 with the ratio slightly affecting the melting point. However, in most practical applications, the impact is not observed as such isotopes are very similar in their characteristic.

- Alloying Composition: the process of alloying normally alters the melting point with significant results. For instance, sterling silver having silver and copper concentrations of 92.5% and 7.5% respectively, has a lower melting point than pure silver.

- Crystal Defect: inhomogeneities such as grain boundaries and other defects such as dislocations can lower the melting point of silver. These shortcomings can develop at the time of processing or manufacturing the metal.

Comparing the Melting Point of Silver to Other Metals

We can go through a quick comparison of the melting point of silver and other melting point of other metals:

| Silver melting point | 961.8°C / 1763.24°F / 1234.95K |

| Melting point of gold | 1064°C / 1947.2°F / 1337K |

| Melting point of bronze | 950°C / 1742°F / 1223.15K |

| Melting point of palladium | 1554.9°C / 2830.82°F / 1828.05 K |

| Melting point of copper | 1085°C / 1984°F / 1358.15 K |

| Melting point of lead | 327.5°C / 621.5°F / 600.65K |

| Melting point of steel | Varies around 1370°C / 2498°F /1643.15K |

| Melting point of iron | 1538°C / 2800.4°F / 1811K |

| Melting point of aluminum | 660.3°C / 1220.54°F / 933.45K |

How to Melt Silver Metal

In silver melting, we heat up the silver to the required melting point before pouring it into molds to produce the required forms. Let us dive straight into the step-by-step procedures involved in the silver melting process:

- Preparation: It is important that you have the right furnace or torch which can reach 961.8°C. For this procedure, you will require all your silver items, crucible, tongs, and safety wear.

- Heating: You can take your silver, place it inside the crucible, and slowly heat it. Be careful not to use high heat, switch between a temperature-regulated furnace or a high-heat torch instead.

- Melting: this is the point where the silver transforms solid metal to molten state. It should be fully melted before moving to the next step.

- Pouring: slowly and gently pour the molten silver into the molds that you have pre-made with your desired form. To handle the hot crucible, use tongs, and be sure to wear protective gear.

- Cooling: let the molten silver cool down and harden inside the molds. After cooling, you can safely remove the cast silver pieces.

- Finishing: you can start by cleaning the silver pieces and polishing their surfaces. You can also refine them based on your application requirements.

Melting Different Grades of Silver

There is an assortment of metals that we can classify as different grades of silver. Such varieties have different fusion temperatures due to the difference in their composition. Let us discuss some of the ways you can melt each of them:

- Fine Silver: it usually has 99.9% purity with a melting point of 961.8°C. Some of the applications in which it is commonly used include jewelry and high-quality electronics.

- Sterling Silver: it is composed of 92.5% silver and 7.5% copper with a melting point of around 893°C. It is widely used in pieces of jewelry, utensils particularly cutleries, and decorative material.

- Coin Silver: with a composition of 90% silver and 10% copper, this grade has a melting point of 875°C. both in ancient and modern times, it is applied in the production of coins and occasionally in ornaments.

Importance of Knowing Silver Melting Point

Knowing the melting point of silver can prove crucial for you, especially in various application fields. Let us briefly look at how important it is:

- In jewelry making, all jewelers require a definite melting point that can produce valuable accessories without distorting the silver.

- In industrial applications, specific temperature regulations are necessary in the electronics and manufacturing industry. This is to ensure that the silver parts are reliable based on application conditions.

- In investment and storage, investors and collectors of silver bullion and silver coins need knowledge of this melting point. This is crucial to them when appraising and managing these assets.

- In educational and scientific research, both science and metallurgical students minimize time carrying out laboratory and experimental exercises using this knowledge.

Conclusion

Having all these details in mind allows you to attain the best outcome when melting fine silver or working with its alloys. It also increases your understanding of this precious metal.

Remember, knowing the melting temperature of silver will help determine a suitable application. Besides, it help you choose an appropriate fabrication mechanism.